Airtight tank type decoking dehydration tank

A closed tank, dehydration tank technology, applied in the direction of fixed filter element filter, gravity filter, lighting and heating equipment, etc., can solve the problems of atmospheric environment pollution, lack of efficient and environmentally friendly dehydration petroleum coke dehydration device, harmful to the body, etc. Improve the effect of filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0030] Referring to the accompanying drawings, the specific implementation is as follows:

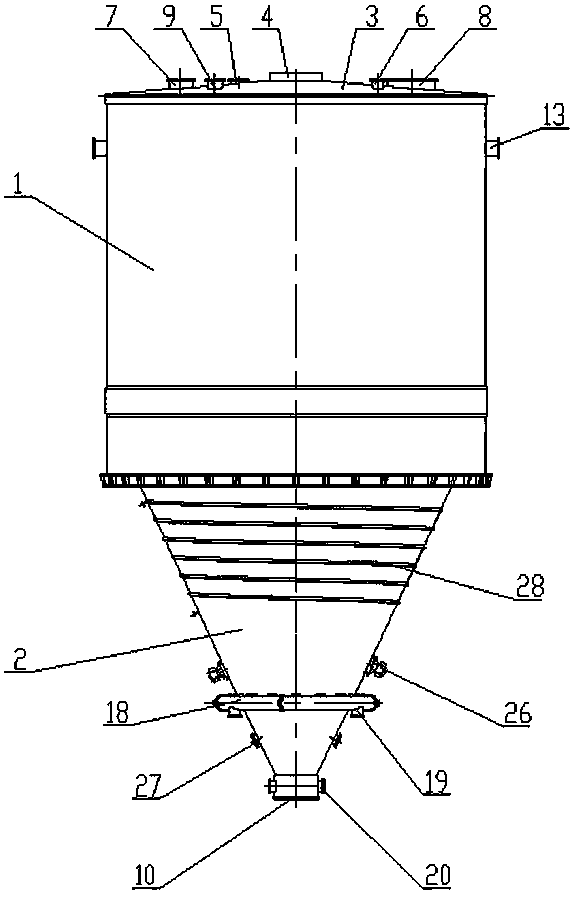

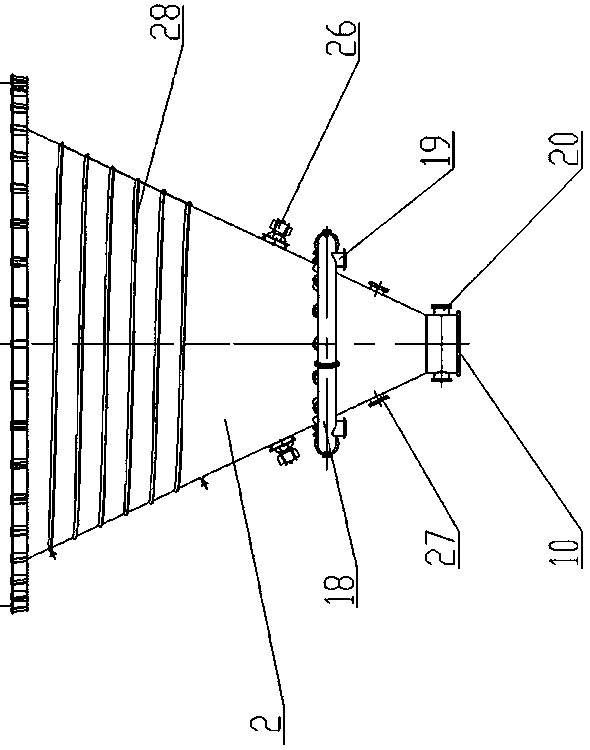

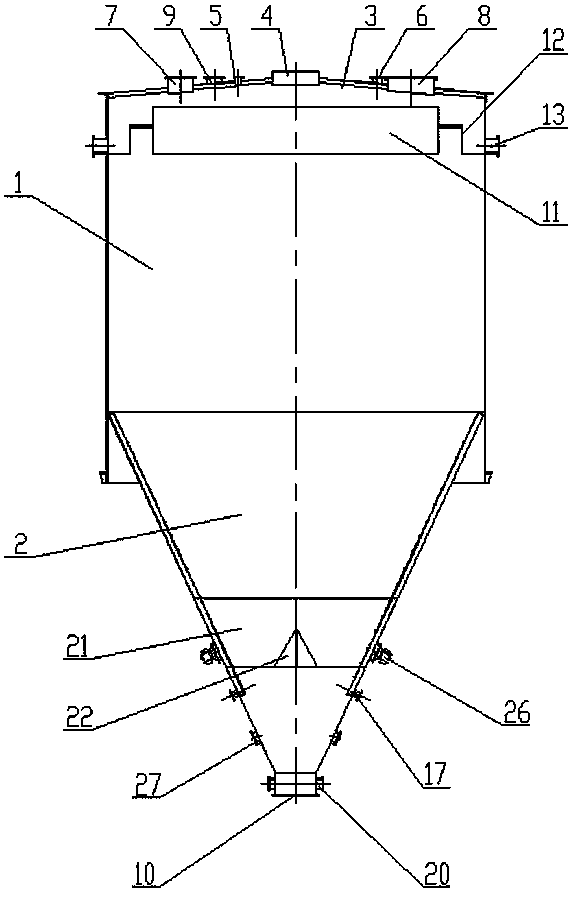

[0031] Such as Figure 1-4 As shown, a closed tank type decoking and dehydration tank includes a vertically arranged cylinder 1 and a cone 2 located below the cylinder 1, the large end of the cone 2 is connected to the bottom end of the cylinder 1, and the cylinder 1 A top cover 3 is installed on the top, and a material inlet 4 is provided on the top cover 3. A material outlet 10 is provided at the small end of the cone 2. The top cover 3 is also provided with an exhaust port 5, a water inlet 6, a manhole 7, maintenance The hole 8 and the nozzle 9 of the level gauge, the cylinder 1 is provided with an overflow assembly, the overflow assembly includes a disc-shaped foam coke baffle 11 and a zigzag overflow set on the outer circumference of the foam coke baffle 11 Weir 12, the zigzag overflow weir 12 is connected with the inner wall of the cylinder 1, and the side wall of the cylinder 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com