Thermosensitive paper and preparation method thereof

A heat-sensitive paper and base paper layer technology, applied in the field of papermaking, can solve the problems of print head damage, printing quality impact, easy fading, etc., and achieve the effect of reducing consumption and reducing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

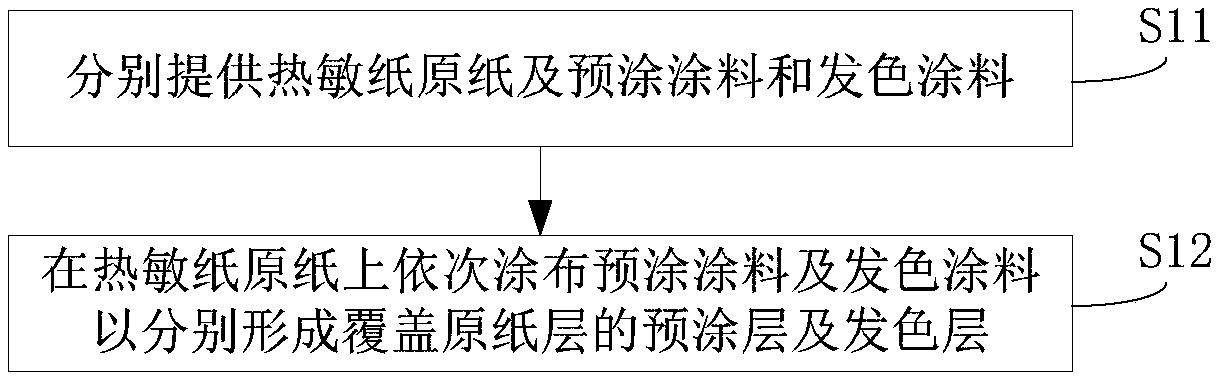

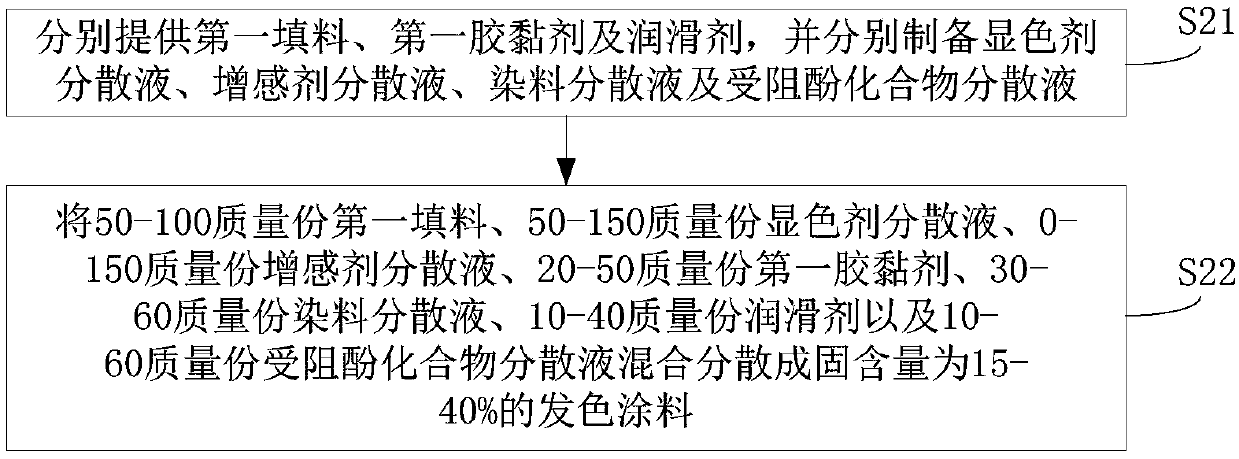

Method used

Image

Examples

Embodiment 1

[0068] 80 parts by mass of calcined kaolin with an oil absorption value of 90g / 100g, 20 parts by mass of hollow plastic pigments, 10 parts by mass of polyvinyl alcohol, and 10 parts by mass of styrene-acrylic latex were mixed and dispersed to form a precoating paint with a solid content of 30%.

[0069]36 parts by mass of 2,4-diphenylsulfonylphenol, 4 parts by mass of polyvinyl alcohol, and 5 parts by mass of magnesium silicate were mixed and dispersed into a dispersion with a concentration of 40%, and ground in a wet grinder until the particle size was 1.0 μm, to obtain the color developer dispersion;

[0070] Mix and disperse 36 parts by mass of 1,2-diphenoxyethane and 4 parts by mass of polyvinyl alcohol into a dispersion with a concentration of 40%, and grind it in a wet mill to a particle size of 1.0 μm to obtain a sensitized agent dispersion;

[0071] 36 parts by mass of crystal violet lactone and 4 parts by mass of polyvinyl alcohol were mixed and dispersed to form a d...

Embodiment 2

[0076] 80 parts by mass of calcined kaolin with an oil absorption value of 70g / 100g, 20 parts by mass of hollow plastic pigments, 10 parts by mass of polyvinyl alcohol, and 10 parts by mass of styrene-acrylic latex were mixed and dispersed to form a precoating paint with a solid content of 30%.

[0077] 36 parts by mass of 2,4-diphenylsulfonylphenol, 4 parts by mass of polyvinyl alcohol, and 5 parts by mass of magnesium silicate were mixed and dispersed into a dispersion with a concentration of 40%, and ground in a wet grinder until the particle size was 1.0 μm, to obtain the color developer dispersion;

[0078] Mix and disperse 36 parts by mass of 1,2-diphenoxyethane and 4 parts by mass of polyvinyl alcohol into a dispersion with a concentration of 40%, and grind it in a wet mill to a particle size of 1.0 μm to obtain a sensitized agent dispersion;

[0079] 36 parts by mass of crystal violet lactone and 4 parts by mass of polyvinyl alcohol were mixed and dispersed to form a ...

Embodiment 3

[0084] 80 parts by mass of calcined kaolin with an oil absorption value of 80g / 100g, 20 parts by mass of hollow plastic pigments, 10 parts by mass of polyvinyl alcohol, and 10 parts by mass of styrene-acrylic latex were mixed and dispersed to form a precoating paint with a solid content of 30%.

[0085] 36 parts by mass of 2,4-diphenylsulfonylphenol, 4 parts by mass of polyvinyl alcohol, and 5 parts by mass of magnesium silicate were mixed and dispersed into a dispersion with a concentration of 40%, and ground in a wet grinder until the particle size was 1.0 μm, to obtain the color developer dispersion;

[0086] Mix and disperse 36 parts by mass of 1,2-diphenoxyethane and 4 parts by mass of polyvinyl alcohol into a dispersion with a concentration of 40%, and grind it in a wet mill to a particle size of 1.0 μm to obtain a sensitized agent dispersion;

[0087] 36 parts by mass of crystal violet lactone and 4 parts by mass of polyvinyl alcohol were mixed and dispersed to form a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com