Anti-precipitation ink based on printer inkjet stability

An anti-sedimentation and stability technology, applied in ink, household utensils, applications, etc., can solve the problems of low service life of printer inkjet nozzles, not bright colors, and easy precipitation, so as to improve physical properties and enhance affinity Harmonization and wettability, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

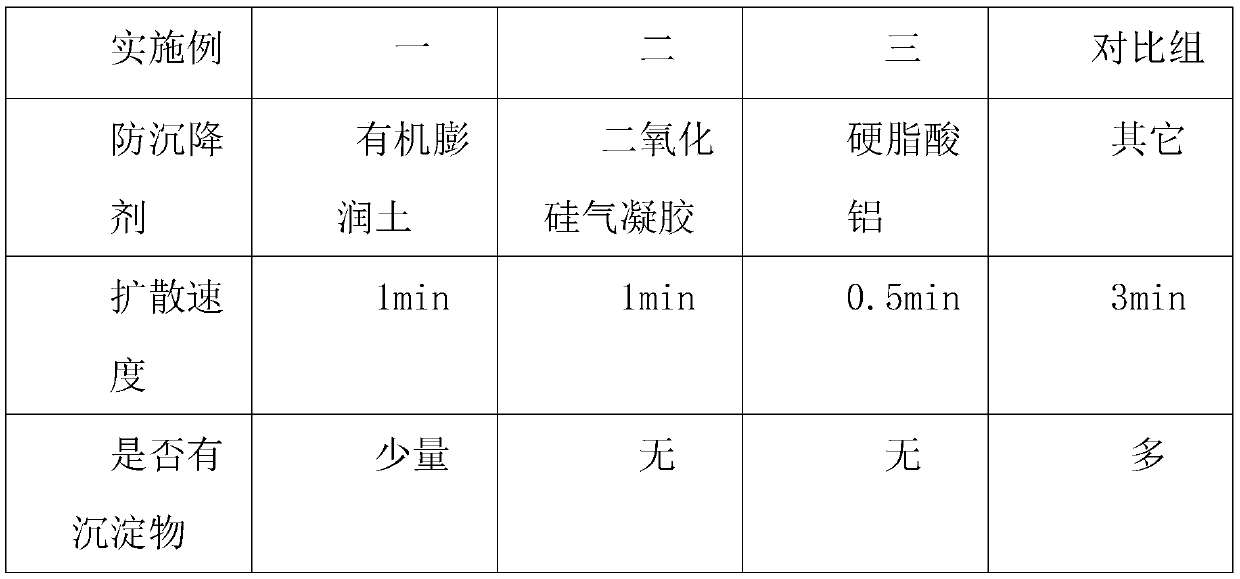

Examples

Embodiment 1

[0029] The present invention provides a kind of anti-sedimentation ink based on inkjet stability of the printer through improvement, including taking parts as the unit of measurement: 30 parts of carbon black powder, 20 parts of deionized water, 1 part of anti-settling agent, 5 parts of humectant, 1 part of PH regulator, 1 part of surfactant, 1 part of dispersant, 0.5 part of lubricant, 1 part of thickener, 0.02 part of preservative, 0.1 part of reactive dye, 0.2 part of antirust agent, 0.2 part of defoamer, Fragrance liquid 1 part.

[0030] Further, the following steps are included:

[0031] S1. Screening: Put the carbon black powder in the raw material into the screen for screening, and the screen mesh for screening the carbon black powder is 100 mesh;

[0032] S2. Production of deionized water: first pass tap water through quartz sand to filter coarser particles of impurities, then pass through reverse osmosis membrane under high pressure, and finally undergo ultraviolet s...

Embodiment 2

[0039] The present invention provides a kind of anti-sedimentation ink based on inkjet stability of the printer through improvement, including taking parts as the unit of measurement: 40 parts of carbon black powder, 30 parts of deionized water, 1 part of anti-settling agent, 5 parts of humectant, 1 part of PH regulator, 1 part of surfactant, 1 part of dispersant, 0.5 part of lubricant, 1 part of thickener, 0.02 part of preservative, 0.1 part of reactive dye, 0.2 part of antirust agent, 0.2 part of defoamer, Fragrance liquid 1 part.

[0040] Further, the following steps are included:

[0041] S1. Screening: Put the carbon black powder in the raw material into the screen for screening, and the screen mesh for screening the carbon black powder is 100 mesh;

[0042] S2. Production of deionized water: first pass tap water through quartz sand to filter coarser particles of impurities, then pass through reverse osmosis membrane under high pressure, and finally undergo ultraviolet ste...

Embodiment 3

[0049] The present invention provides a kind of anti-sedimentation ink based on inkjet stability of the printer through improvement, including taking parts as the unit of measurement: 50 parts of carbon black powder, 40 parts of deionized water, 1 part of anti-settling agent, 5 parts of humectant, 1 part of PH regulator, 1 part of surfactant, 1 part of dispersant, 0.5 part of lubricant, 1 part of thickener, 0.02 part of preservative, 0.1 part of reactive dye, 0.2 part of antirust agent, 0.2 part of defoamer, Fragrance liquid 1 part.

[0050] Further, the following steps are included:

[0051] S1. Screening: Put the carbon black powder in the raw material into the screen for screening, and the screen mesh for screening the carbon black powder is 100 mesh;

[0052] S2. Production of deionized water: first pass tap water through quartz sand to filter coarser particles of impurities, then pass through reverse osmosis membrane under high pressure, and finally undergo ultraviolet s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com