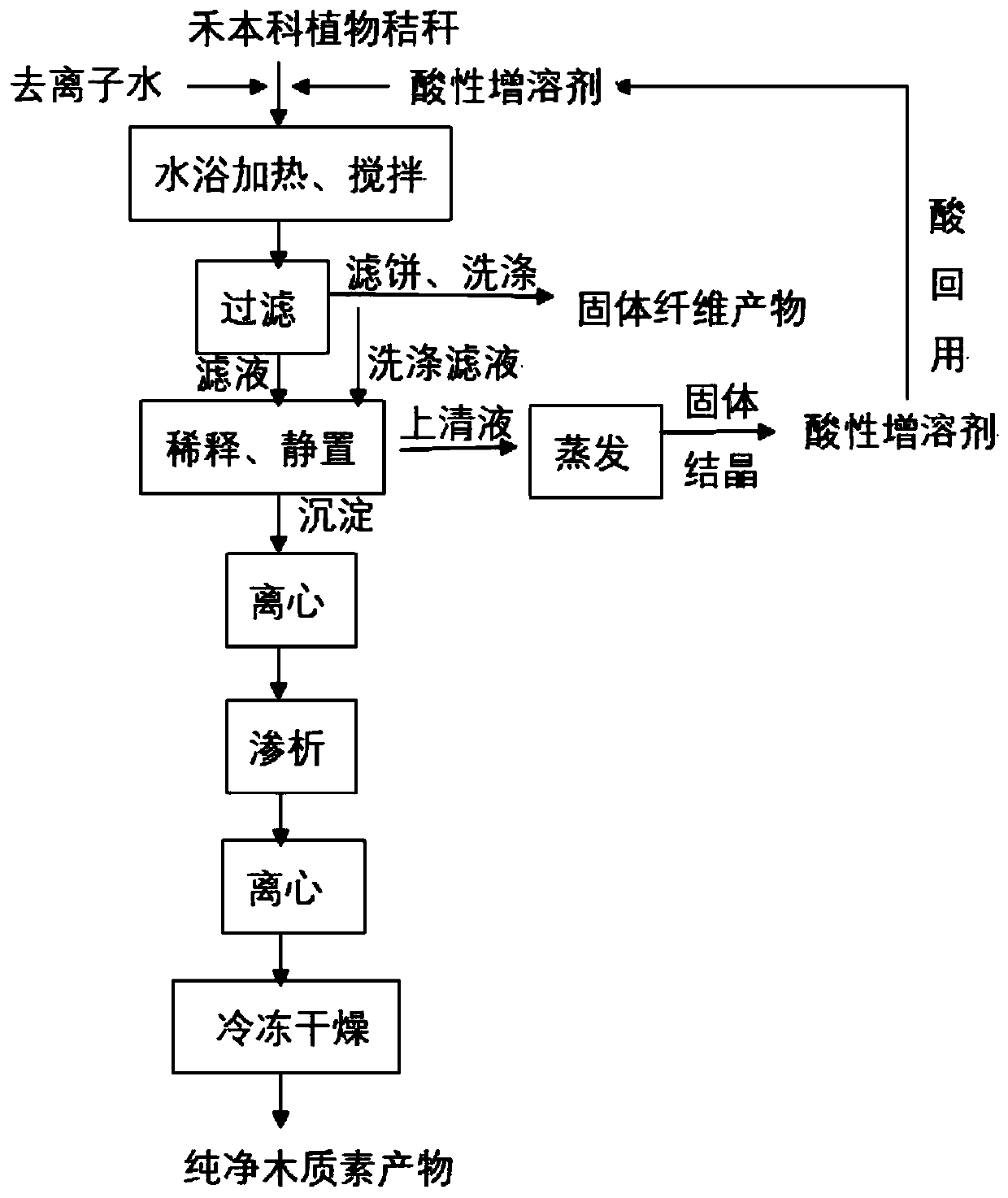

Method for separating chemical components of grass family plants and purifying lignin

A gramineous plant and phytochemical technology, which is applied in the field of separating chemical components of gramineous plant straws and purifying lignin, can solve the problems of secondary pollution of chemicals, high requirements on experimental conditions, and complicated separation technology, and achieves the degree of polycondensation. Low, high yield, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The total weight of the experiment is 200g, and the ratio of raw material weight to total weight is 1:10.

[0057] (1) Pulverization: select the dried gramineous plant stalks and pulverize them with a pulverizer to obtain gramineous plant stalk residues for subsequent use;

[0058] (2) Acid hydrolysis: take by weighing 20g of gramineous plant straw debris, 60g p-toluenesulfonic acid and 120g deionized water, wherein p-toluenesulfonic acid accounts for 30% of the total weight, and put the gramineous plant straw debris into a porous circle In the bottom flask, put p-toluenesulfonic acid and deionized water into the Erlenmeyer flask and stir evenly. Put the porous round bottom flask and the Erlenmeyer flask into the water bath at the same time, and fix them with a test tube rack, and heat them in the water bath to 80 ℃, add the p-toluenesulfonic acid solution in the Erlenmeyer flask to the porous round bottom flask, continue to stir for 30min, after the reaction is complet...

Embodiment 2

[0068] The total weight of the experiment is 200g, and the ratio of raw material weight to total weight is 1:10.

[0069] (1) pulverizing: method is with embodiment 1;

[0070] (2) Acid hydrolysis: take by weighing 20g of gramineous plant straw debris, 90g p-toluenesulfonic acid and 90g deionized water, wherein p-toluenesulfonic acid accounts for 45% of the total weight, and put the gramineous plant straw debris into a porous circle In the bottom flask, put p-toluenesulfonic acid and deionized water into the Erlenmeyer flask and stir evenly. Put the porous round bottom flask and the Erlenmeyer flask into the water bath at the same time, and fix them with a test tube rack, and heat them in the water bath to 80 ℃, add the p-toluenesulfonic acid solution in the Erlenmeyer flask to the porous round-bottom flask, continue stirring for 15 minutes, after the reaction is completed, add 200 g of deionized water to the porous round-bottom flask to obtain a fiber suspension, and set asid...

Embodiment 3

[0080] The total weight of the experiment is 200g, and the ratio of raw material weight to total weight is 1:10.

[0081] (1) pulverizing: method is with embodiment 1;

[0082] (2) Acid hydrolysis: Weigh 20g of gramineous plant straw debris, 120g p-toluenesulfonic acid and 60g deionized water, wherein p-toluenesulfonic acid accounts for 60% of the total weight, and put the gramineous plant straw debris into a porous circle In the bottom flask, put p-toluenesulfonic acid and deionized water into the Erlenmeyer flask and stir evenly, put the porous round bottom flask and the Erlenmeyer flask into the water bath at the same time, fix them with a test tube rack, and heat them in the water bath to 60 ℃, add the p-toluenesulfonic acid solution in the Erlenmeyer flask to the porous round bottom flask, continue to stir for 30min, after the reaction is completed, add 200g of deionized water to the porous round bottom flask to obtain a fiber suspension, and set aside;

[0083] (3) filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com