Preparation method of polymerized tannic acid coated high-activity aluminium powder/silicon powder

A tannic acid, high activity technology, used in offensive equipment, compressed gas generation, non-explosive/non-thermal agent components, etc. Abundance, low equipment requirements, and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

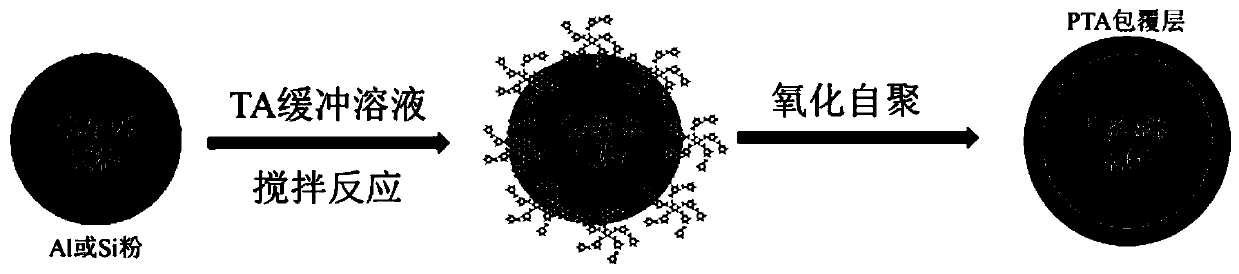

Method used

Image

Examples

Embodiment 1

[0028] Dissolve 0.22g of Tris buffer reagent in 100mL of methanol / N,N-dimethylformamide solvent with a volume ratio of 1:1, adjust the pH to 8.5, then add 0.20g of tannic acid (TA), stir and dissolve evenly A tannic acid-buffer solution was obtained; then 0.10 g of nano-aluminum powder was added, stirred for 1 hour from the polymerization reaction, filtered and washed to obtain a nano-aluminum powder coated with polymerized tannic acid.

[0029] figure 2 with Figure 4 They are the SEM and TEM images of the nano-aluminum powder and the nano-aluminum powder coated with polymerized tannic acid prepared in this example, respectively. By comparison, it is found that the polymerized tannic acid has formed a uniform coating layer on the surface of the nano-aluminum powder. Image 6 It is the XRD pattern of nano-aluminum powder and the nano-aluminum powder coated with polymerized tannic acid prepared under the present embodiment. By comparison, it can be found that the aluminum pea...

Embodiment 2

[0031] Dissolve 0.22g of Tris buffer reagent in 100mL of methanol / N,N-dimethylformamide solvent with a volume ratio of 1:1, adjust the pH to 9.6, then add 0.20g of tannic acid (TA), stir and dissolve evenly A tannic acid-buffer solution was obtained; then 0.10 g of nano silicon powder was added, stirred for 6 hours from the polymerization reaction, filtered and washed to obtain nano silicon powder coated with polymerized tannic acid.

[0032] image 3 with Figure 5 The SEM and TEM photographs of the nano-silicon powder and the polymerized tannic acid-coated nano-silicon powder prepared in this example are the SEM and TEM photographs respectively. It is found by comparison that the polymerized tannic acid has formed a uniform coating layer on the surface of the nano-silicon powder. Figure 7 The XRD pattern of the nano-silicon powder and the polymerized tannic acid-coated nano-silicon powder prepared under this example is shown. By comparison, it can be found that the silicon...

Embodiment 3

[0034] Dissolve 0.22g of Tris buffer reagent in 100mL of methanol / N,N-dimethylformamide solvent with a volume ratio of 1:1, adjust the pH to 8.5, then add 0.20g of tannic acid (TA), stir and dissolve evenly A tannic acid-buffer solution was obtained; then 0.10 g of micron aluminum powder was added, stirred for 1 h from the polymerization reaction, filtered and washed to obtain micron aluminum powder coated with polymerized tannic acid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com