Special jointing agent for flexible sheet and preparation and construction method thereof

A technology of flexible sheet and jointing agent, applied in construction, building structure and other directions, can solve the problems of high cost, inability to overcome efflorescence cracking, etc., and achieve the effect of short process, improved outdoor durability, and simple and easy construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0049] The preparation method of the special jointing agent for flexible sheets provided by this application has simple process and short process; and it can be made into finished products in the factory without adding water and blending by workers on the construction site, which ensures the quality of the jointing agent; the produced flexible sheet The special pointing agent has the properties of pan-alkali resistance, crack resistance and weather resistance; the raw material is simple, the finished product is cheap, and the defects of the prior art can be overcome.

[0050] According to some embodiments of the preparation method of the special grouting agent for flexible sheets of the present invention, preferably, the components contained in the mixed emulsion and the weight percentages of each component are: pure acrylic emulsion with a low glass transition temperature 40- 45%, high weather resistance silicone acrylic emulsion 15-20%, coalescent 0.4-0.5%, propylene glycol 0...

Embodiment 1

[0056] 1. Prepare mixed emulsion:

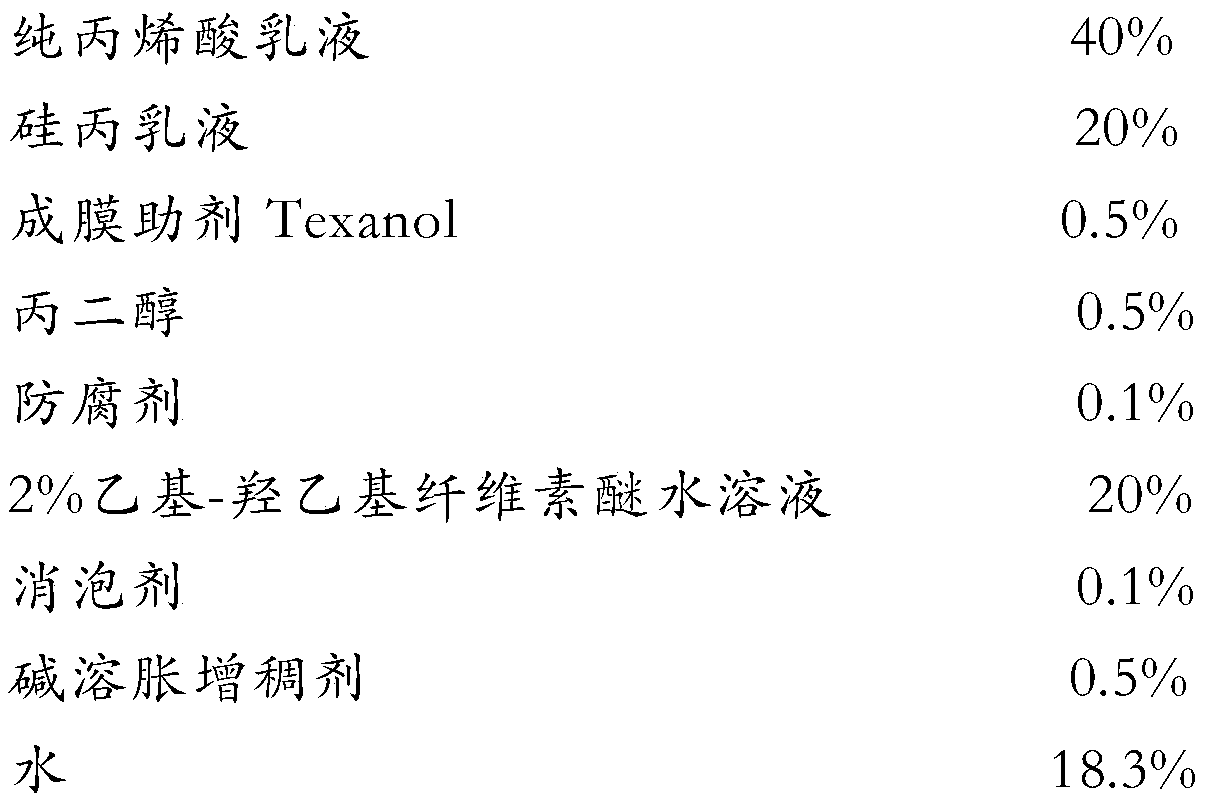

[0057] The mixed emulsion formula is:

[0058]

[0059] Put the formula amount of pure acrylic emulsion, silicon acrylic emulsion and water into the clean reaction kettle, turn on the disperser at 300-500 rpm, pre-mix the emulsion and water, stir well, then add the formula amount of film-forming Auxiliary Texanol, propylene glycol and stir evenly, gradually increase the stirring speed, add preservatives, 2% ethyl-hydroxyethyl cellulose ether aqueous solution, defoamer, and mix the above materials at 500-800 rpm After 10 minutes, when the bubbles in the solution in the kettle are defoamed, gradually increase the speed of the disperser, and slowly add an alkali-swellable thickener to thicken, and the viscosity of the prepared mixed emulsion is between 65-95KU.

[0060] 2. Preparation of special pointing agent (gray):

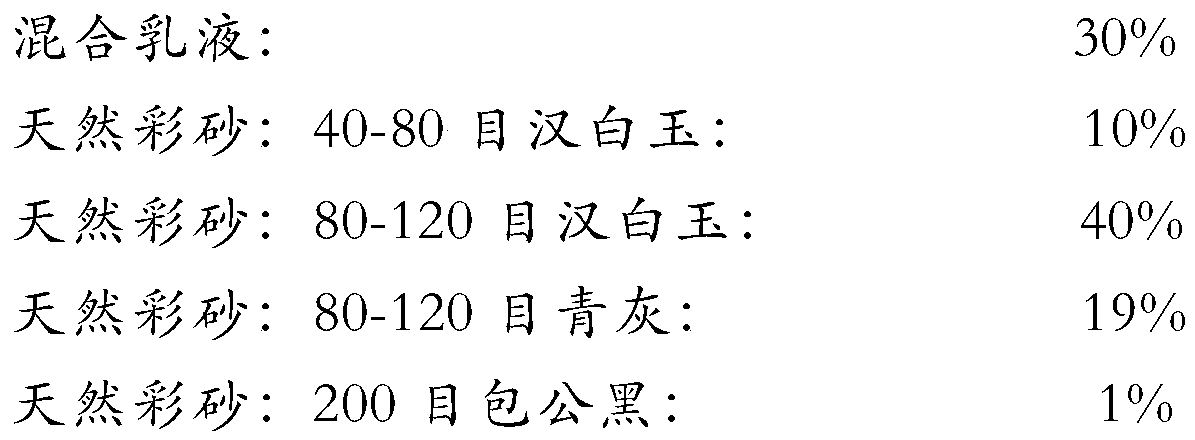

[0061] The formula of special pointing agent is:

[0062]

[0063] Put the mixed emulsion of the formula into the cle...

Embodiment 2

[0065] 1. Prepare mixed emulsion:

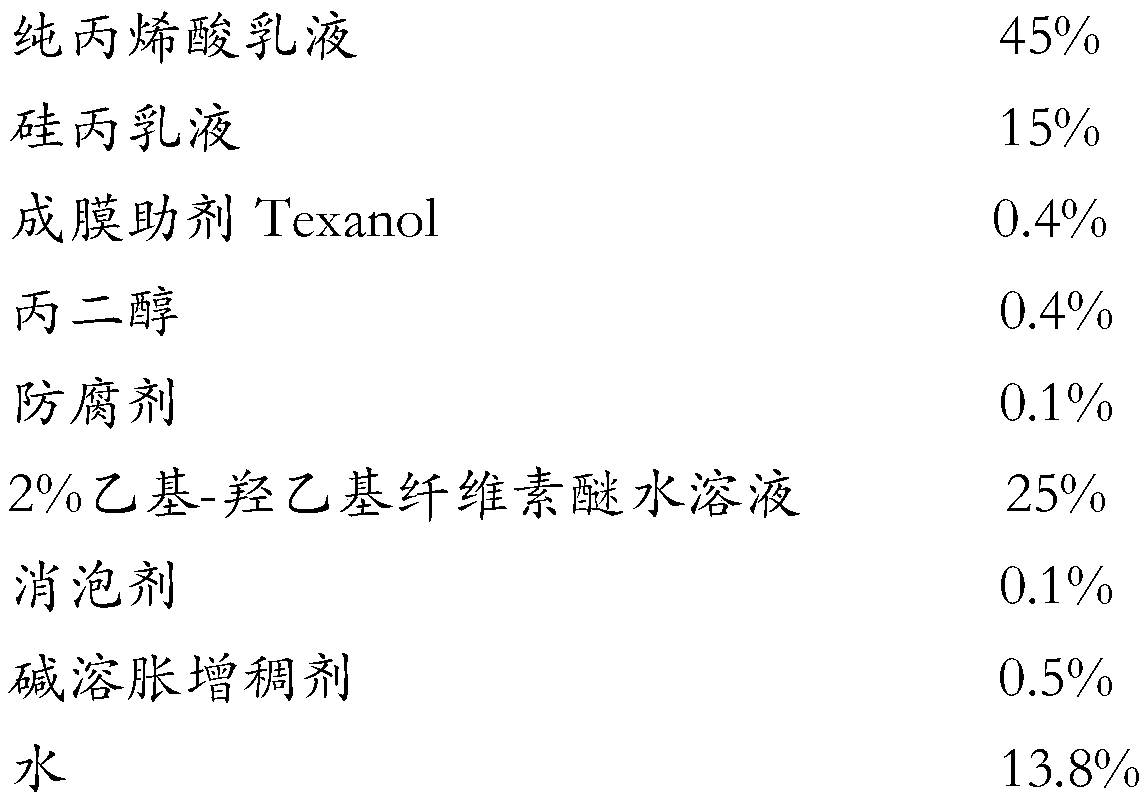

[0066] The mixed emulsion formula is:

[0067]

[0068] Put the formula amount of pure acrylic emulsion, silicon acrylic emulsion and water into the clean reaction kettle, turn on the disperser at 300-500 rpm, pre-mix the emulsion and water, stir well, then add the formula amount of film-forming Auxiliary Texanol, propylene glycol and stir evenly, gradually increase the stirring speed, sequentially add preservatives, 2% ethyl-hydroxyethyl cellulose ether aqueous solution, defoamer, mix at 500-800 rpm for 15 minutes, wait When defoaming until there are few bubbles in the solution in the kettle, gradually increase the speed of the disperser, and slowly add alkali swelling thickener to thicken, and the viscosity of the prepared mixed emulsion is between 65-95KU.

[0069] 2. Preparation of special pointing agent (black):

[0070] The formula of special pointing agent is:

[0071]

[0072] Put the mixed emulsion in the clean reaction ket...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com