Centralized treatment control method for cutting fluids of carving centers

A control method and centralized processing technology, which can be used in engraving, decorative arts, processing models, etc., can solve the problems of large workload, high work intensity, time-consuming and laborious, etc., to achieve uniform concentration, ensure stability, and improve quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

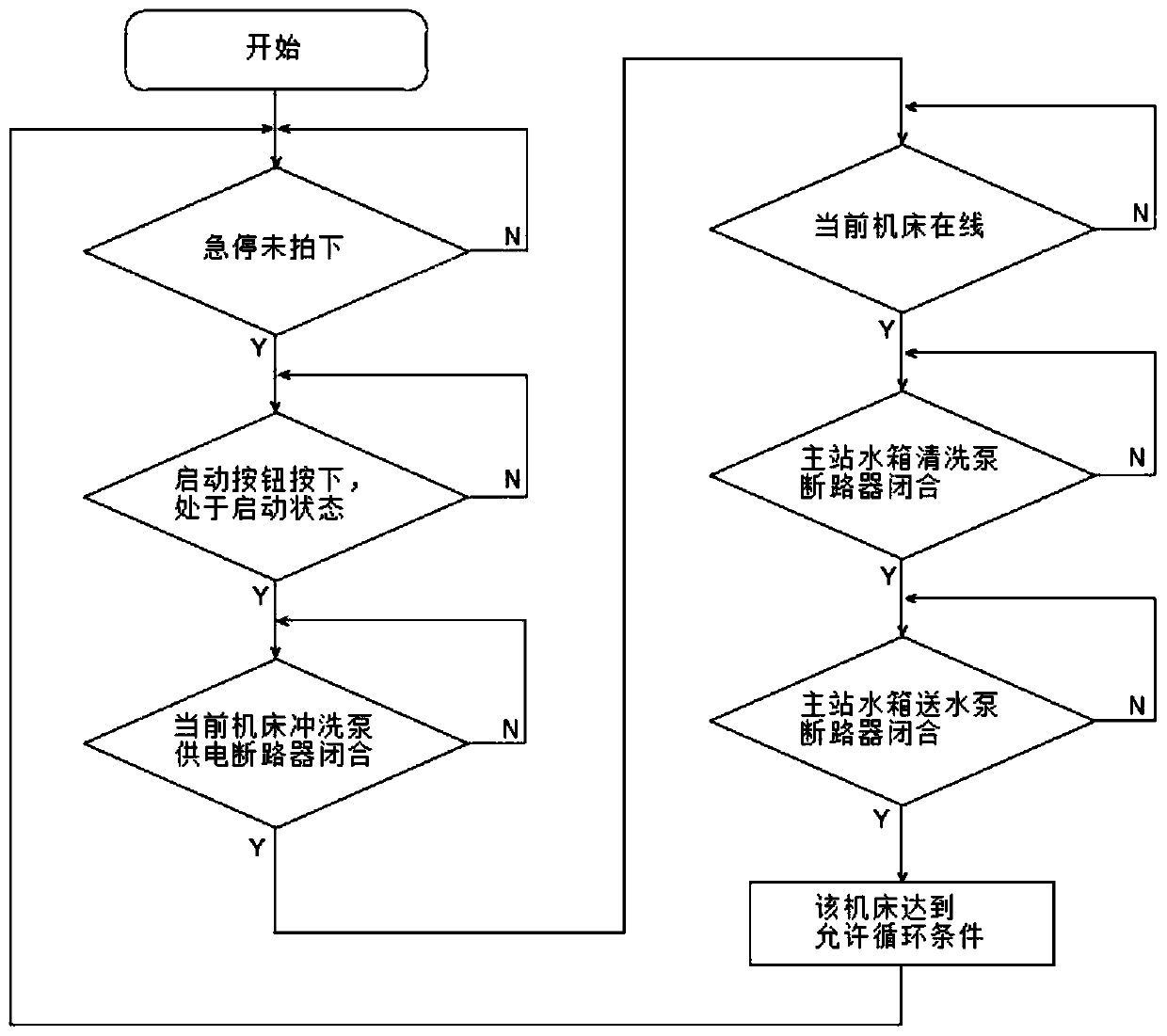

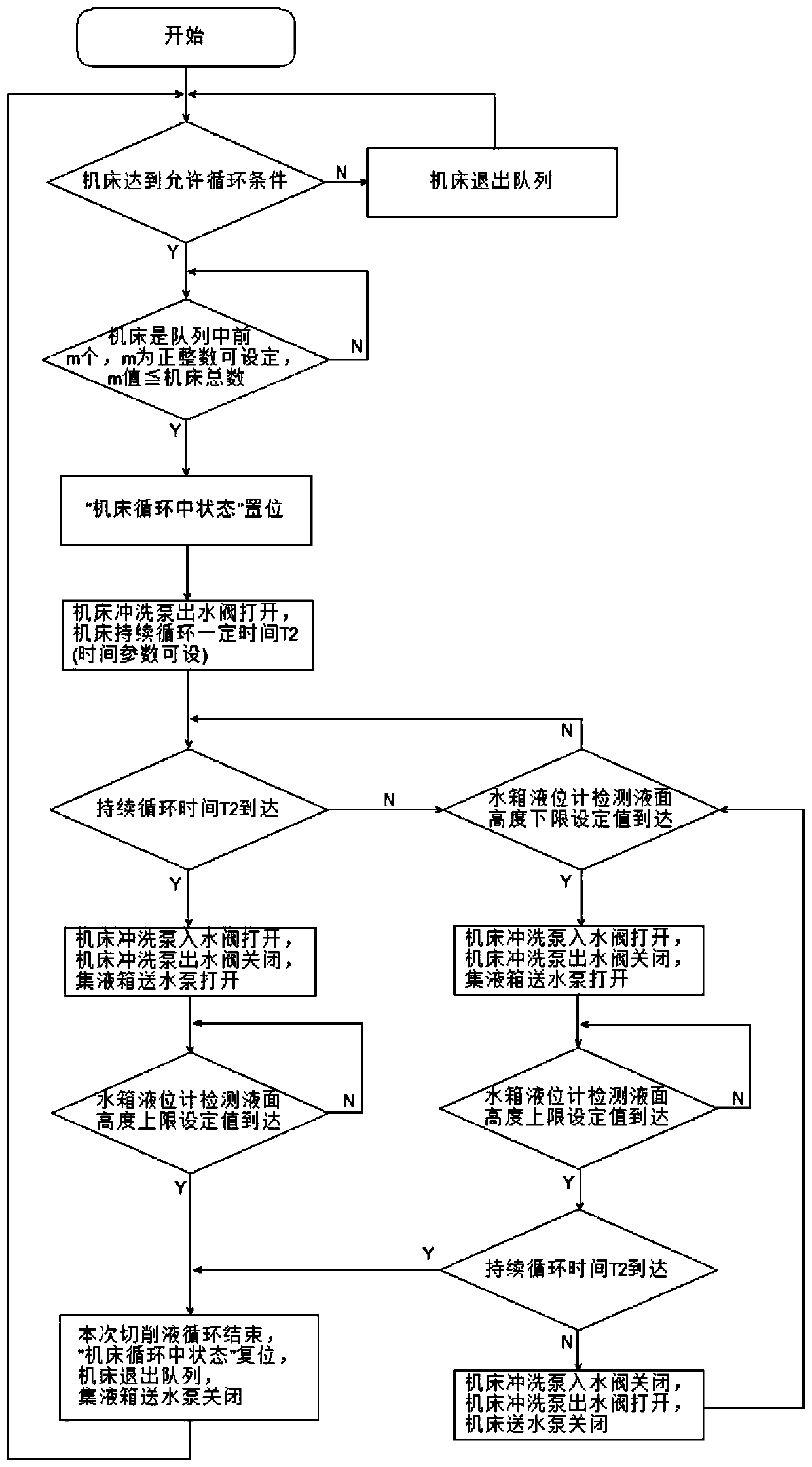

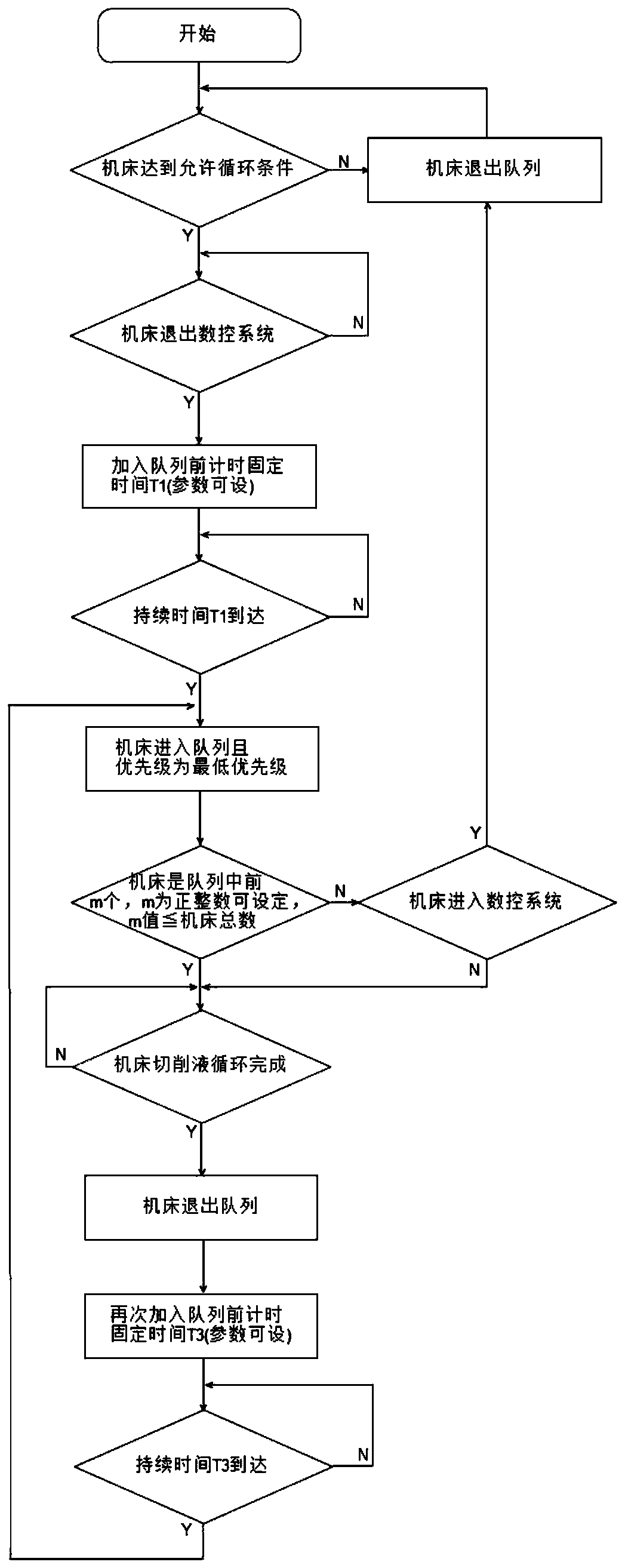

[0047] The present invention is an engraving center cutting fluid centralized processing control system, including n engraving centers and their cutting fluid water tanks, an electrical control cabinet, a liquid collection tank, a main liquid return pipeline and a main liquid delivery pipe Road, each branch cutting fluid circuit, n is a positive integer, among them, each engraving center cutting fluid water tank contains a flushing pump, 3 solenoid valves (water outlet valve, water inlet valve, machine tool flushing valve) and 1 liquid level sensor. The liquid tank includes a water delivery pump, a clean water pump and a liquid level sensor.

[0048] The electrical control cabinet is equipped with n "online / offline" knobs, n is a positive integer, and the "ON / OFF" of each knob indicates whether the cutting fluid of the engraving center water tank participates in automatic circulation.

[0049] ①Install the following components at the water tank of the single engraving center: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com