Full-automatic wet prepreg impregnation machine

A prepreg, fully automatic technology, applied in coating and other directions, can solve the problems of difficult control of fiber cloth resin content, low production efficiency, unreasonable structural design equipment, etc., to solve the problem of uncontrollable product thickness, solve health and Safety issues, the effect of solving the problem of rich and poor rubber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

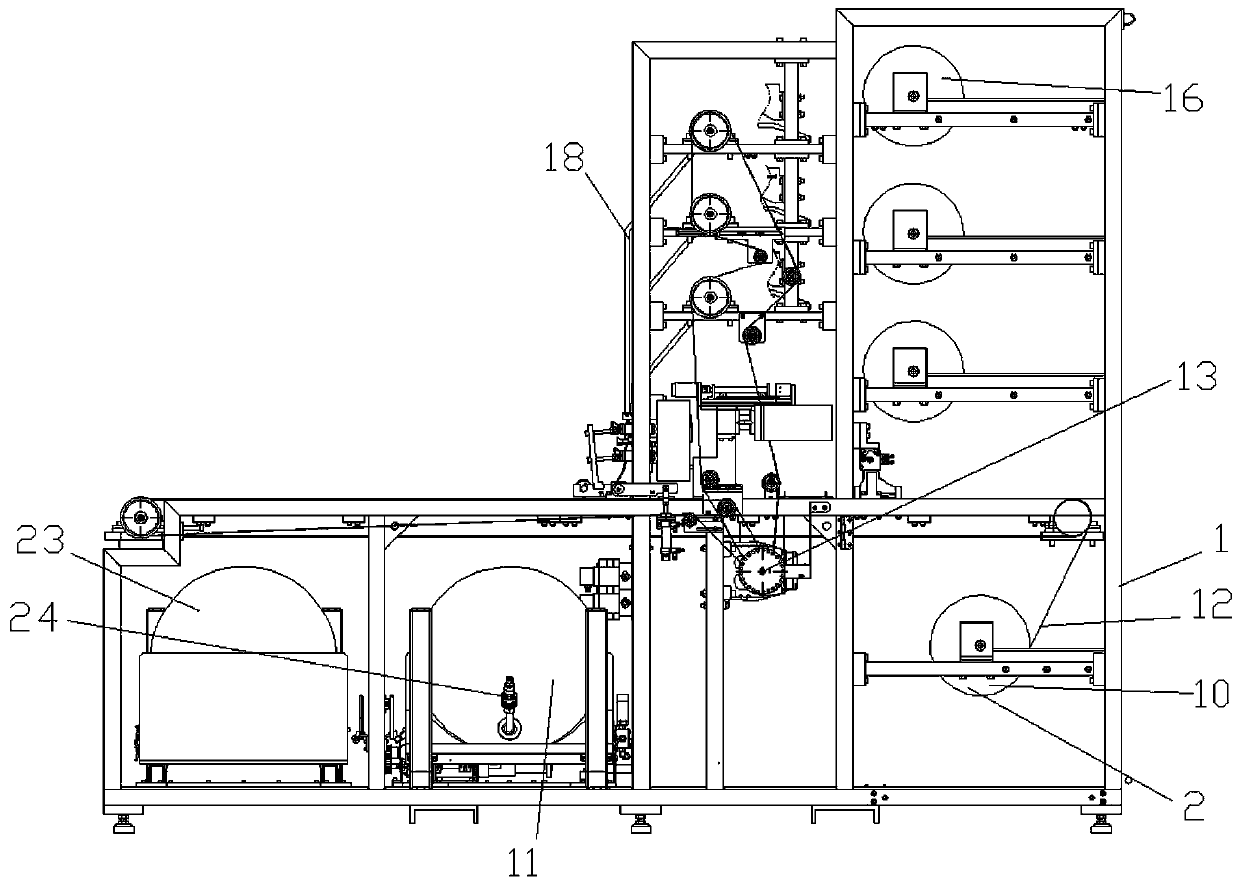

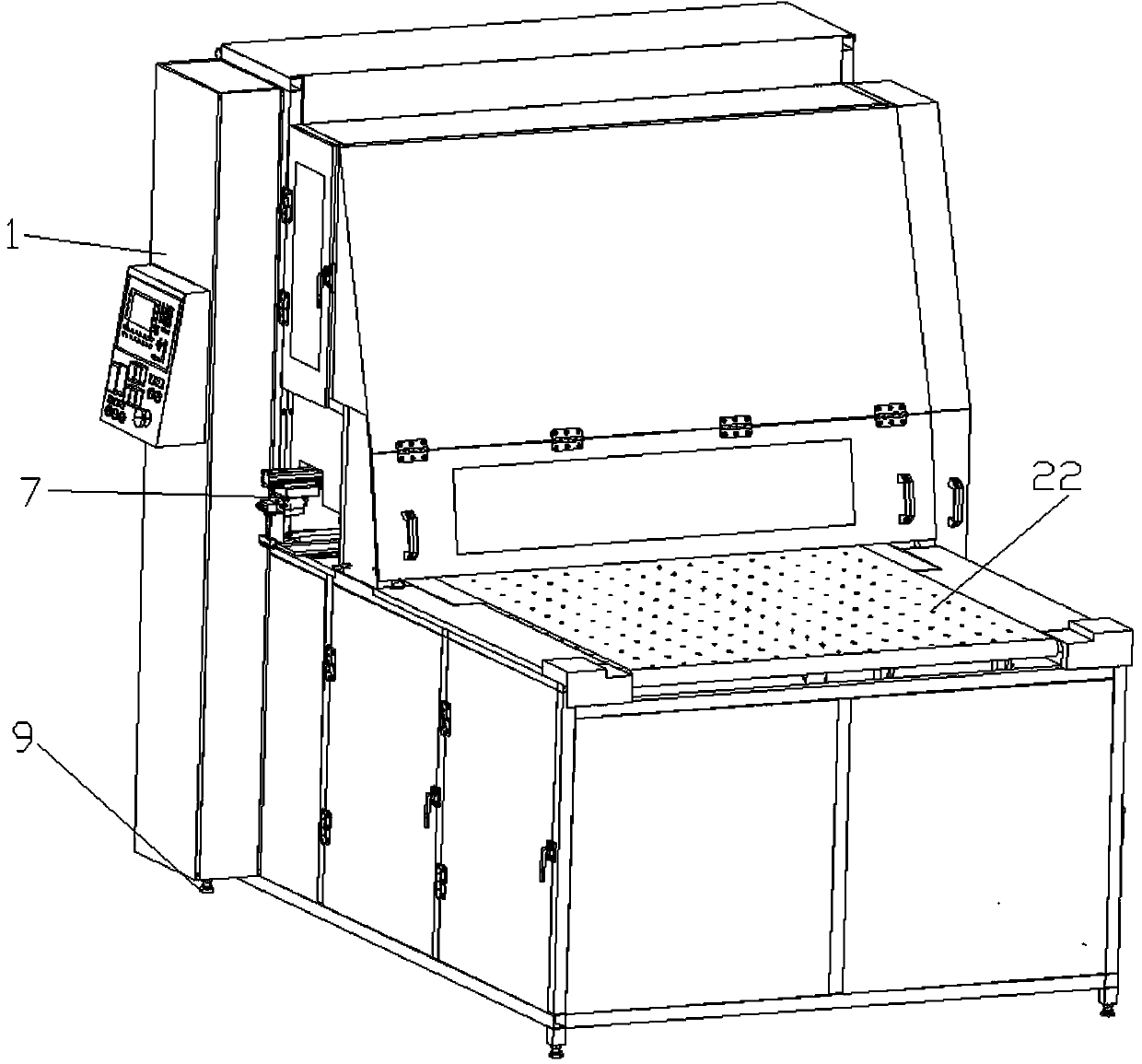

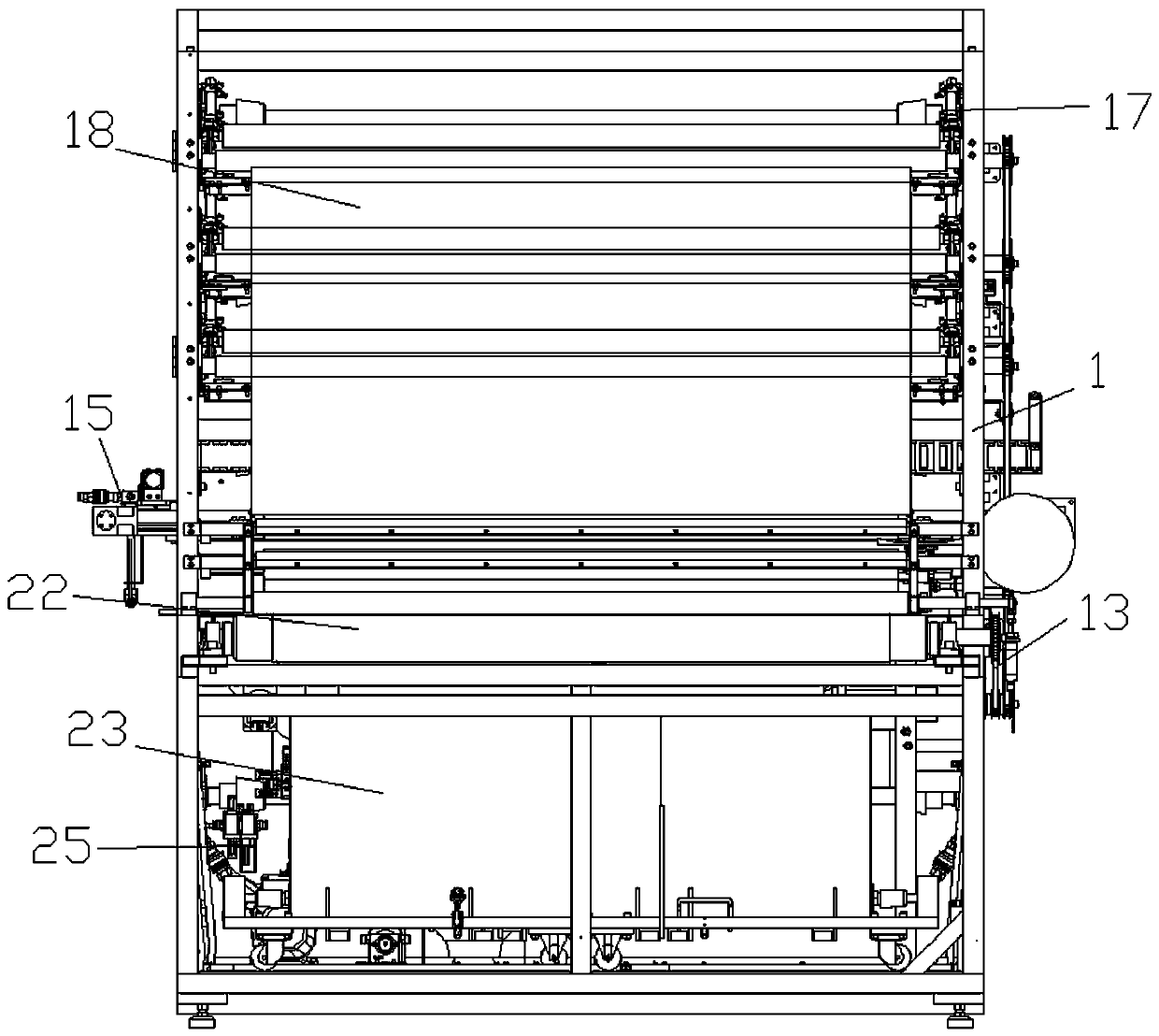

[0027] Example: such as figure 1 , figure 2 , image 3 , Figure 4As shown, it includes a main body frame 1, which is equipped with equipment adjustable anchor bolts 9, fiber cloth station 16, fiber cloth pressing mechanism 17, resin mixing and spraying mechanism 15, adhesion film cutting mechanism 14, adhesion film Mechanism 2, fiber cloth guiding mechanism 18, fiber cloth cutting mechanism 19, fiber cloth soaking mechanism 20, vacuum adsorption mechanism 21, resin and curing agent pumping mechanism 25; Roller, the outer side of the fiber cloth roller is wound with fiber cloth, and the main frame 1 is provided with three fiber cloth stations 16 with the same structure and correspondingly arranged up and down; the fiber cloth pressing mechanism 17 includes a lower pressing roller connected to the main frame 1 through bearing rotation , the upper part of the lower pressing roller is provided with an upper pressing roller, and the main frame 1 is provided with three fiber cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com