Machining tool and machining process of special-shaped stainless steel products

A stainless steel and product technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of high processing difficulty, low efficiency, low product accuracy, etc., achieve rapid and stable mass production, ensure product quality and Accuracy, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

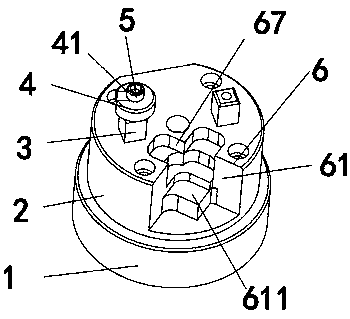

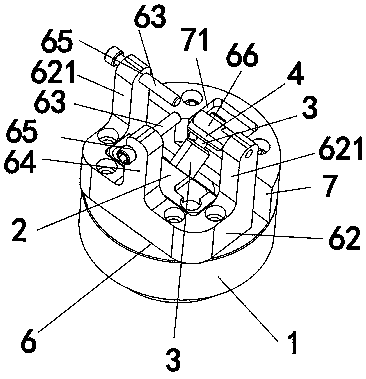

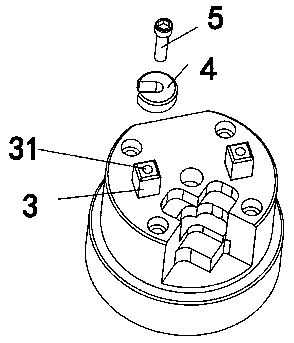

[0023] Such as figure 1 As shown, the processing tooling for special-shaped stainless steel products described in this embodiment includes product clamping mechanism one installed on the fixed part of the machining center and product clamping mechanism two installed on the rotating part of the lathe; product clamping mechanism one and The product clamping mechanism 2 includes a fixed block 1, a positioning block 3, a pressure block 4 and a compression bolt 5. A spacer 2 is fixed on the fixed block, a positioning block 3 is fixed on the spacer 2, and a threaded hole 31 is provided on the positioning block 3. , the sleeve body of the special-shaped stainless steel product is set on the top of the positioning block, and the pressure block is placed on the top surface of the sleeve body of the special-shaped stainless steel product. The head and the top surface of the briquetting block are pressed together to fix the sleeve body of the special-shaped stainless steel product; the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com