Speed-up vacuum upper-suction casting mould

A casting mold and vacuum technology, which is applied in the field of instant vacuum suction casting molds, can solve problems such as affecting the dimensional accuracy of workpieces.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

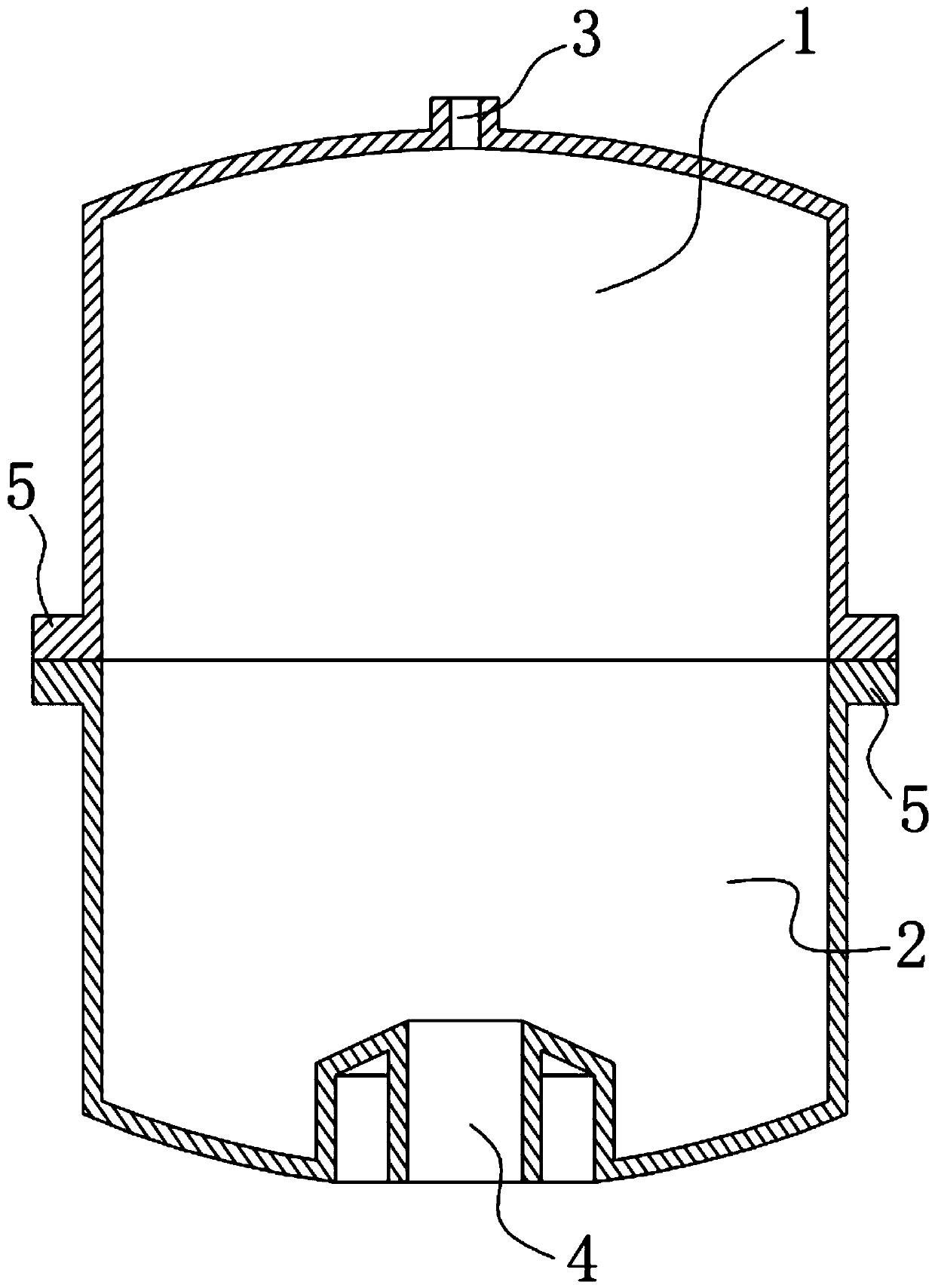

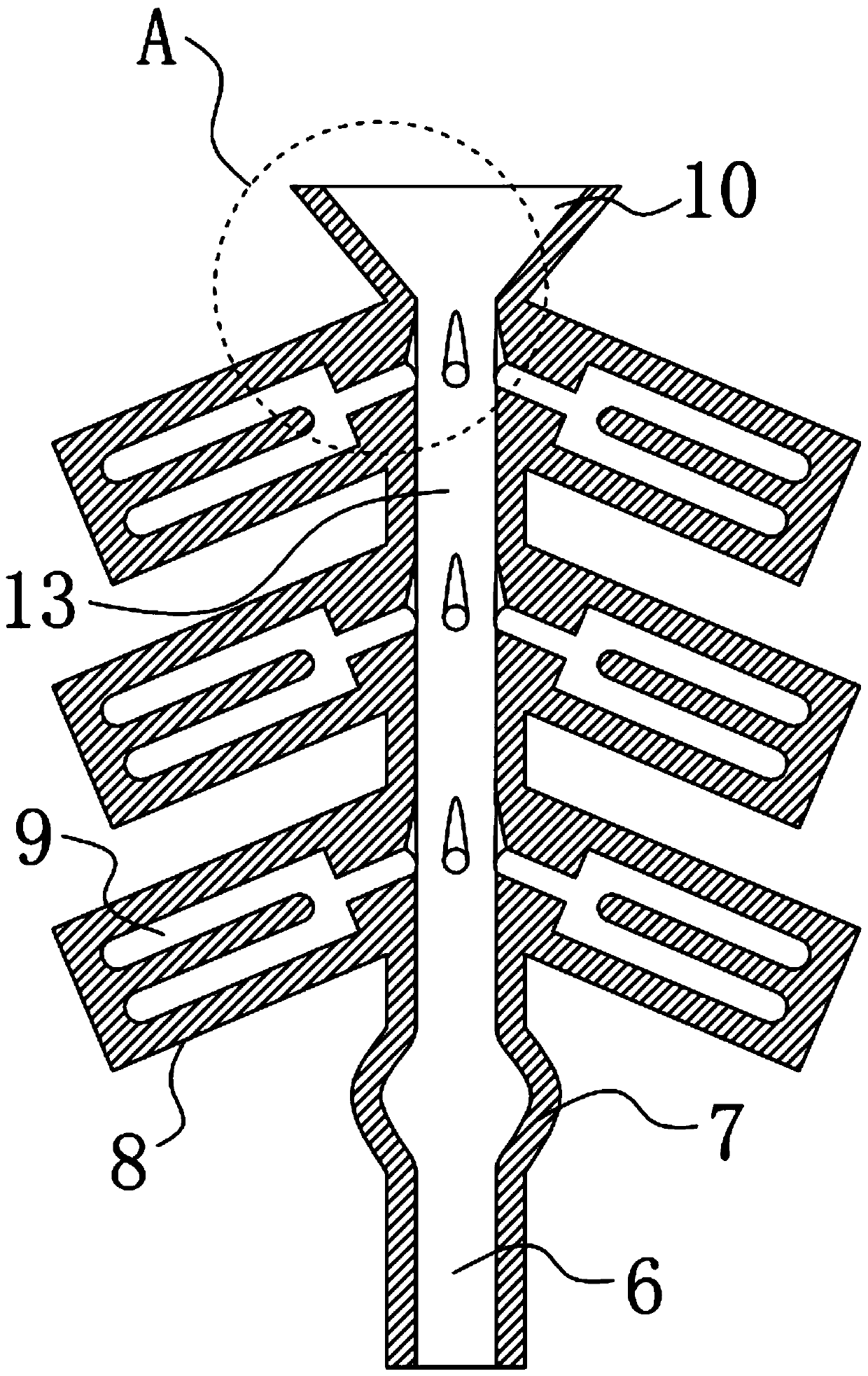

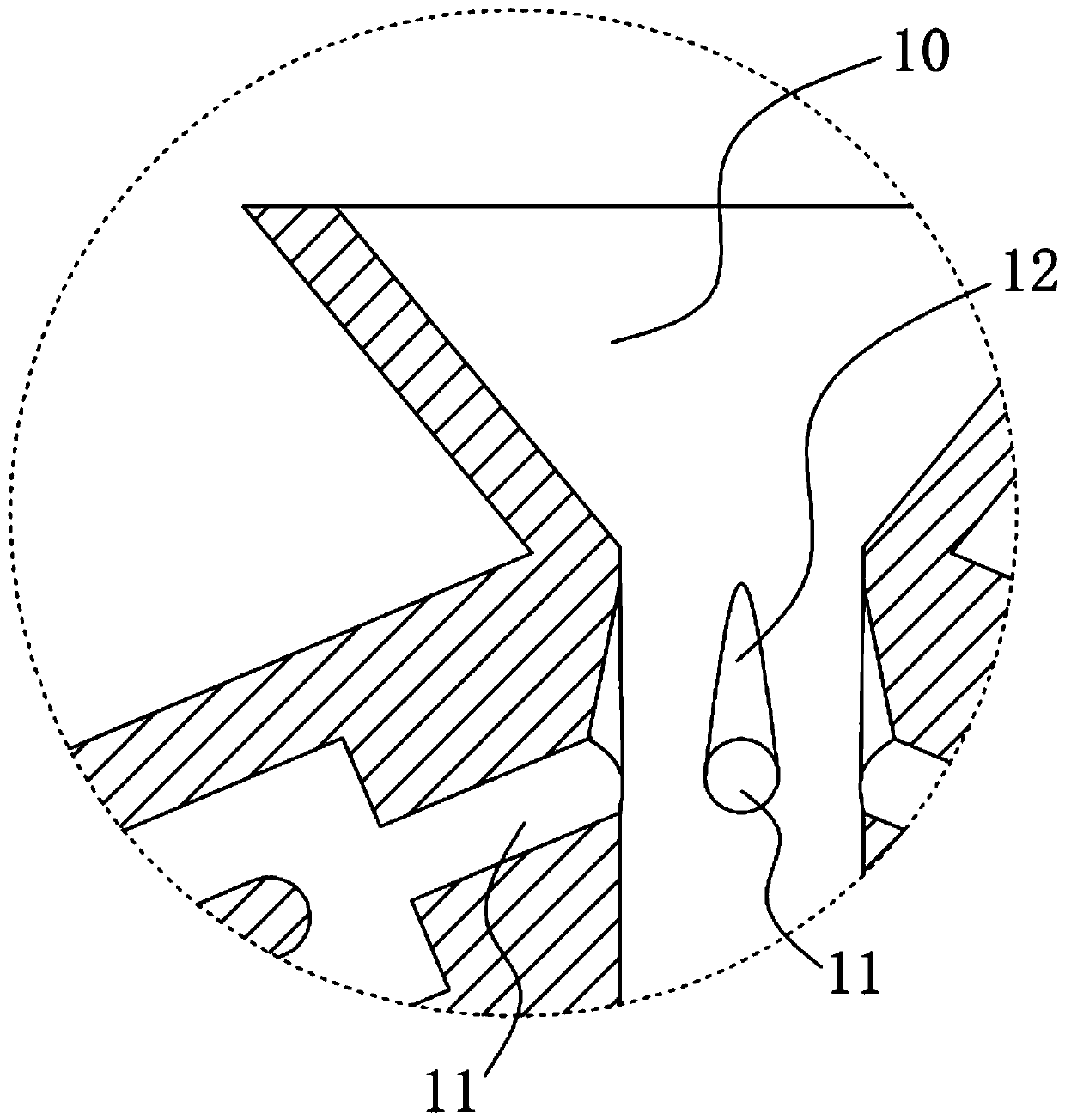

[0028] In order to achieve the purpose of the present invention, a quick-acting vacuum up-suction casting mold includes: a mold tree 8, including a vertical pipe 13 that runs through vertically, and the vertical pipe 13 is obliquely connected with several mold cavities 9, and the mold cavities 9 pass through The liquid flow passage 11 is connected with the vertical pipe 13, and along the radially outward direction of the vertical pipe 13, the height of the liquid flow passage 11 gradually decreases; the transition groove 12 is recessed in the inner wall of the vertical pipe 13, and each liquid flow passage 11 are intersected with a transition groove 12, along the direction from top to bottom, the recessed depth of each transition groove 12 gradually deepens, and the plane where the transition line between the transition groove 12 and the flow channel 11 is lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com