Organic solvent resistant ultrafiltration membrane and preparation method and application thereof

A technology that is resistant to organic solvents and organic solvents, applied in chemical instruments and methods, membranes, membrane technologies, etc., can solve the problems of loss of basic performance of ultrafiltration membranes, erosion of ultrafiltration membranes, and high maintenance costs, and achieve good market application prospects. , The effect of preventing the erosion of organic solvents and the simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

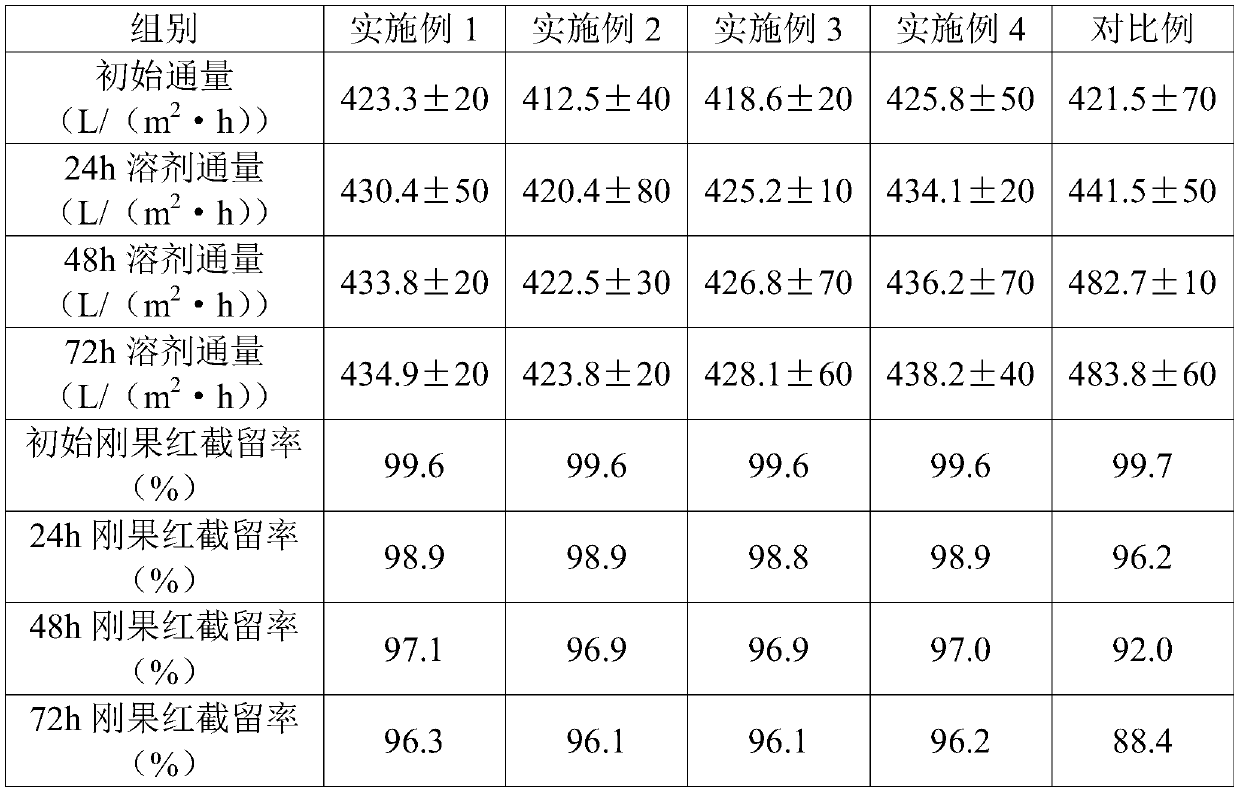

Examples

Embodiment 1

[0035] Weigh 100g of polyetherimide, 600g of N-methylpyrrolidone and 50g of polyvinylpyrrolidone, mix and stir for 1 hour, and defoam in a vacuum defoamer for 20 minutes to obtain a casting solution;

[0036] Use a flat-plate scraping machine to scrape the casting solution. The thickness of the scraped film is 100 μm. After the scraped film, it is dried at normal temperature and pressure for 1 min. The dried film is immersed in deionized water, and the temperature of the deionized water is maintained at 20°C, immersion time 10min, take out to obtain ultrafiltration membrane;

[0037] Add 50g of ethylenediamine to 400g of tetrahydrofuran, mix and cool down to 0°C, stir for 10 minutes to obtain a membrane pore modification solution, immerse the ultrafiltration membrane in the membrane pore modification solution, graft and modify it for 1 hour, take it out and place it at room temperature Drying for 20min under normal pressure, obtain the first modified ultrafiltration membrane; ...

Embodiment 2

[0040] Weigh 200g of polysulfone, 800N,N-dimethylformamide and 100g of polyvinyl alcohol, mix, stir for 2h, and defoam in a vacuum defoamer for 30min to obtain a casting solution;

[0041] Use a flat-plate scraping machine to scrape the casting solution. The thickness of the scraped film is 400 μm. After scraping, dry it at normal temperature and pressure for 2 minutes. The dried film is immersed in ethanol, and the temperature of the deionized water is kept at 30. ℃, immersion time 10min, take out to obtain ultrafiltration membrane;

[0042] Add 150g of ethylenediamine to 500g of tetrahydrofuran, mix and cool down to 10°C, stir for 20 minutes to obtain a membrane pore modification solution, immerse the ultrafiltration membrane in the membrane pore modification solution, graft and modify it for 2 hours, take it out and place it at room temperature Dry 40min under normal pressure, obtain the modified ultrafiltration membrane for the first time;

Embodiment 3

[0045] Weigh 150g of polyethersulfone, 700N,N-dimethylacetamide and 70g of polyvinylpyrrolidone, mix, stir for 1.5h, and defoam in a vacuum defoamer for 30min to obtain a casting solution;

[0046] Use a flat-plate scraping machine to scrape the casting solution. The thickness of the scraped film is 200 μm. After scraping, dry it at normal temperature and pressure for 1 min, and immerse the dried film in a mixed solution of deionized water and ethanol. The temperature of the mixed solution is 30°C, the immersion time is 20min, and the ultrafiltration membrane is obtained by taking it out;

[0047] Add 100g of ethylenediamine to 450g of tetrahydrofuran, mix and cool down to 8°C, and stir for 15 minutes to obtain a membrane pore modification solution, immerse the ultrafiltration membrane in the membrane pore modification solution, graft and modify it for 1 hour, take it out and place it at room temperature Drying for 20min under normal pressure, obtain the first modified ultrafi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com