Quinoa shredded egg thin pancake and manufacture method thereof

A production method and technology of quinoa eggs, which are applied in the field of food processing, can solve the problems of uneven surface of egg skin, limitations of industrial production, low qualification rate, etc., and achieve good egg liquid coagulation characteristics, good uniformity, and soft taste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

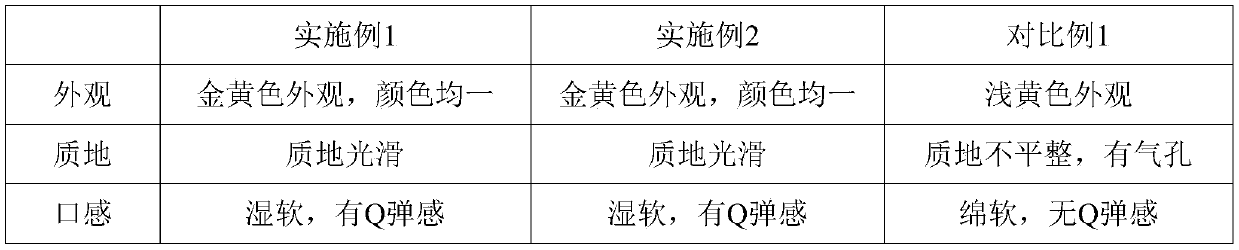

Examples

Embodiment 1

[0025] A kind of preparation method of quinoa egg skin, comprises the following steps:

[0026] (1) Raw egg pretreatment: beat the raw egg with an egg beater, and then separate the egg white and egg yolk;

[0027] (2) Egg liquid premixing: Weigh 4 parts of water, 45 parts of egg white, and 50 parts of egg yolk by weight, stir in advance, and gradually add 15 parts of quinoa flour at a stirring speed of 400r / min, stir well until there is no agglomeration, and record as Mixture A;

[0028] (3) Seasoning oil configuration: Weigh 6 parts of vegetable oil, 1 part of glycerin, and 3 parts of butter, heat and melt the butter in advance, fully mix with vegetable oil and glycerin, and record it as mixed liquid B;

[0029] (4) Preparation of slurry: mix mixed solution A and mixed solution B, add 1 part of glyceryl monostearate, 0.5 part of glucono-δ-lactone, mix thoroughly to obtain a slurry, and set aside;

[0030] (5) degassing: the slurry obtained in step (4) is degassed, the vacuu...

Embodiment 2

[0034] A kind of preparation method of quinoa egg skin, comprises the following steps:

[0035] (1) Raw egg pretreatment: beat the raw egg with an egg beater, and then separate the egg white and egg yolk;

[0036] (2) Egg liquid premixing: Weigh 5 parts of water, 50 parts of egg white, and 50 parts of egg yolk by weight, and stir in advance, at a stirring speed of 400r / min, gradually add 15 parts of quinoa flour, stir well until there is no agglomeration, and record as Mixture A;

[0037] (3) Seasoning oil configuration: weigh 4 parts of vegetable oil, 2 parts of glycerin, and 5 parts of butter, heat and melt the butter in advance, fully mix with vegetable oil and glycerin, and record it as mixed solution B;

[0038] (4) Preparation of slurry: mix mixed solution A and mixed solution B, add 2 parts of glyceryl monostearate and 1 part of glucono-δ-lactone, mix thoroughly to obtain a slurry, and set aside;

[0039] (5) degassing: the slurry obtained in step (4) is degassed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com