Multistage ionization rotating magnetic field acceleration spiral wave plasma source

A plasma source and rotating magnetic field technology, applied in the direction of plasma, electrical components, etc., can solve the problems of high processing precision of electrostatic gate, reduce the service life of plasma source, restrict the service life of plasma source, etc., and achieve electrodeless design , Various propellants, the effect of increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and examples. It should be understood that the following examples are intended to facilitate the understanding of the present invention, and have no limiting effect on it.

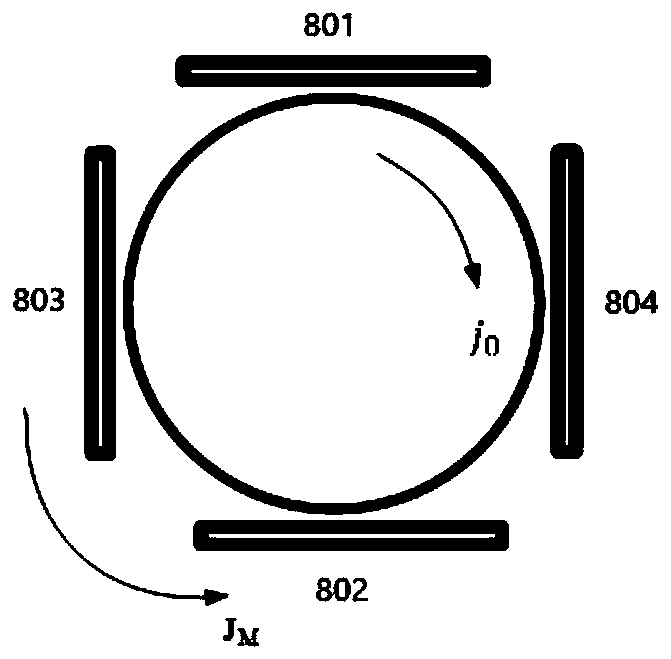

[0027] Such as figure 1 As shown, the multi-stage ionized rotating magnetic field accelerated helicon wave plasma source of the present invention includes a discharge chamber 1, a first-stage helicoid antenna 2, a first-stage helicoid magnetic coil 3, a second-stage helicoid antenna 4, a second-stage The helical wave magnetic coil 5 , the magnetic mirror structure and the rotating magnetic field acceleration coil 8 , the magnetic mirror structure includes the first-stage magnetic confinement magnetic coil 6 and the second-stage magnetic confinement magnetic coil 7 . Among them, the discharge chamber 1, the first-stage helical wave antenna 2, the first-stage helical wave magnetic coil 3, the second-sta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com