An active clamp flyback converter and its control method

A technology of flyback converter and control method, applied in control/regulation system, DC power input conversion to DC power output, instrument, etc., can solve the problem of failure to realize zero voltage turn-on, increase on-state loss, and affect the service life of devices and other problems to achieve the effect of avoiding the reverse surge of excitation current, improving circuit EMI, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

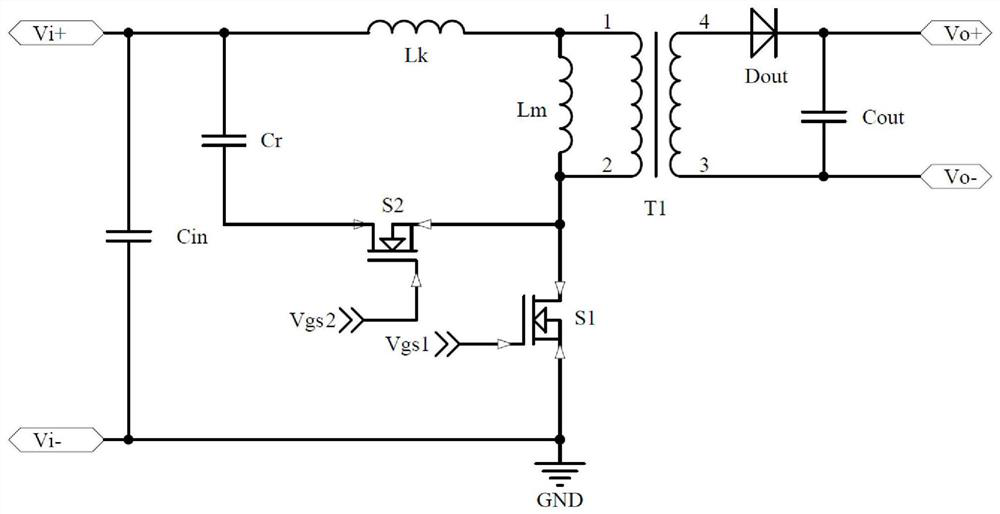

[0030] Figure 5 Shown is a schematic diagram of an active clamp flyback converter implemented by the present invention. The circuit includes a main power circuit, a main clamp circuit, an auxiliary clamp circuit and an output rectifying and filtering circuit. Among them, the main power circuit is formed by connecting the transformer T1 and the main switching tube S1; the main clamping circuit is formed by connecting the main clamping switching tube S2 and the main clamping capacitor Cr; the auxiliary clamping circuit is composed of the auxiliary clamping switching tube S3, the auxiliary clamping The clamping capacitor Cc is formed by connecting the auxiliary clamping diode Dc; the output rectification filter circuit is formed by connecting the output rectifying diode Dout and the output capacitor Cout. The detection method to determine the working state of the circuit adopts the method of comparing the detected input voltage with the set input voltage threshold; the input vol...

no. 2 example

[0057] The schematic diagram of the active clamp flyback converter is the same as that of Embodiment 1. The difference between this embodiment and the first embodiment is that in the driving mode 1 of the second embodiment, the main clamp tube S2 and the auxiliary clamp switch tube S3 are connected to The main switching tube S1 is in a complementary driving state. Therefore, this embodiment only provides the working principle of the driving mode 1.

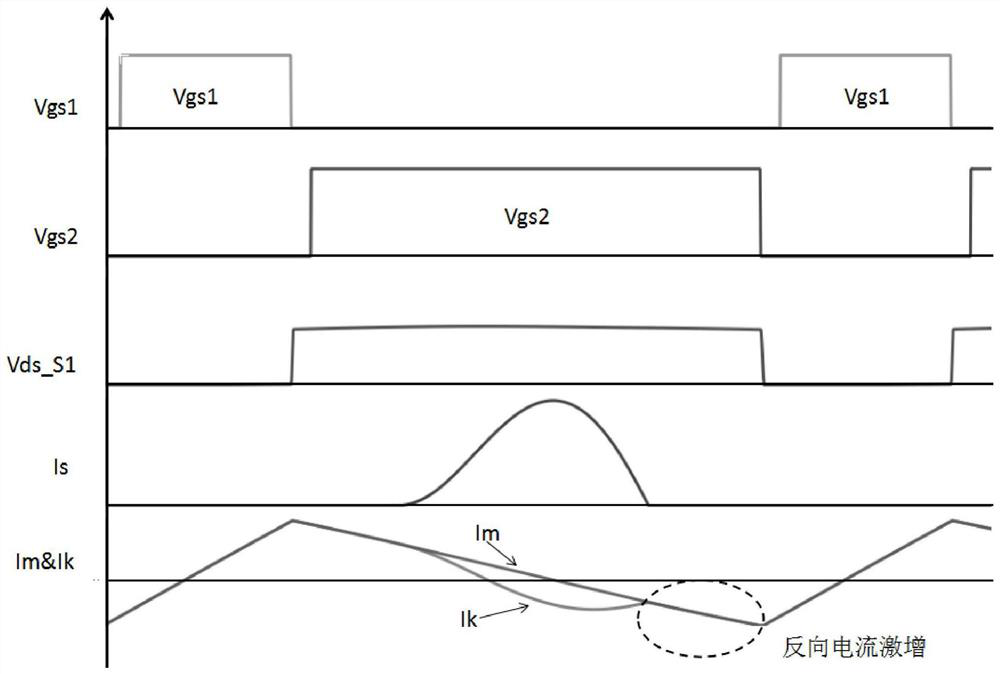

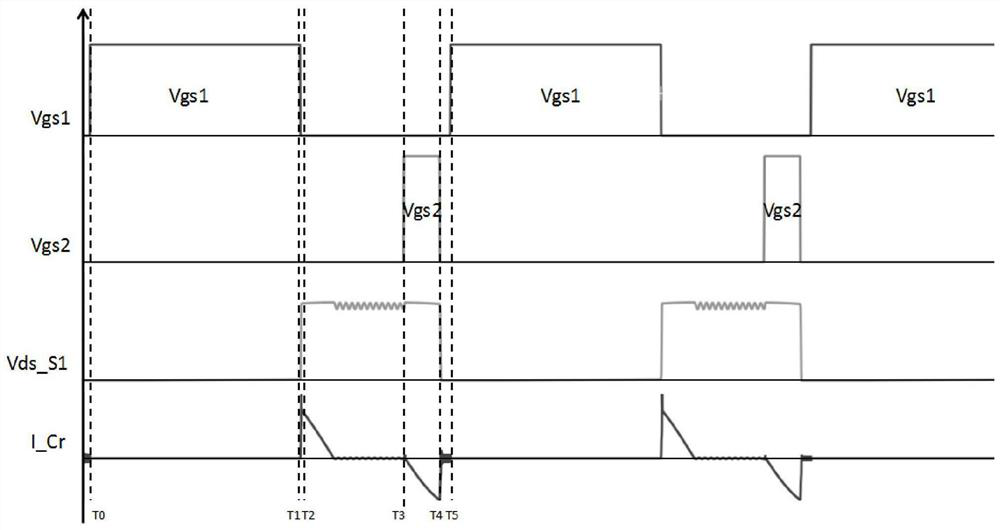

[0058] When the input voltage is lower than the set threshold, the circuit is in a continuous working state. At this time, the driving mode 1 is adopted. At this time, the auxiliary clamping switch S3 is in the non-working state, and the main clamping tube S2 and the main switching tube S1 are in the complementary driving state. . Figure 8 The working waveform diagram is shown, in which Vgs1 is the driving waveform of the main switching tube S1, Vgs2 is the driving waveform of the main clamping switching tube S2, Vds_S1 is the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com