Electric main shaft reliability loading testbed for load comprehensive decoupling

A loading test and electric spindle technology, which is applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve the problem of inability to accurately simulate the axial and radial cutting force and cutting torque of the electric spindle, and the difficulty of mixing loads. Decoupling, low loading frequency and other issues to achieve the effect of ensuring loading accuracy, reducing impact, and solving partial load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

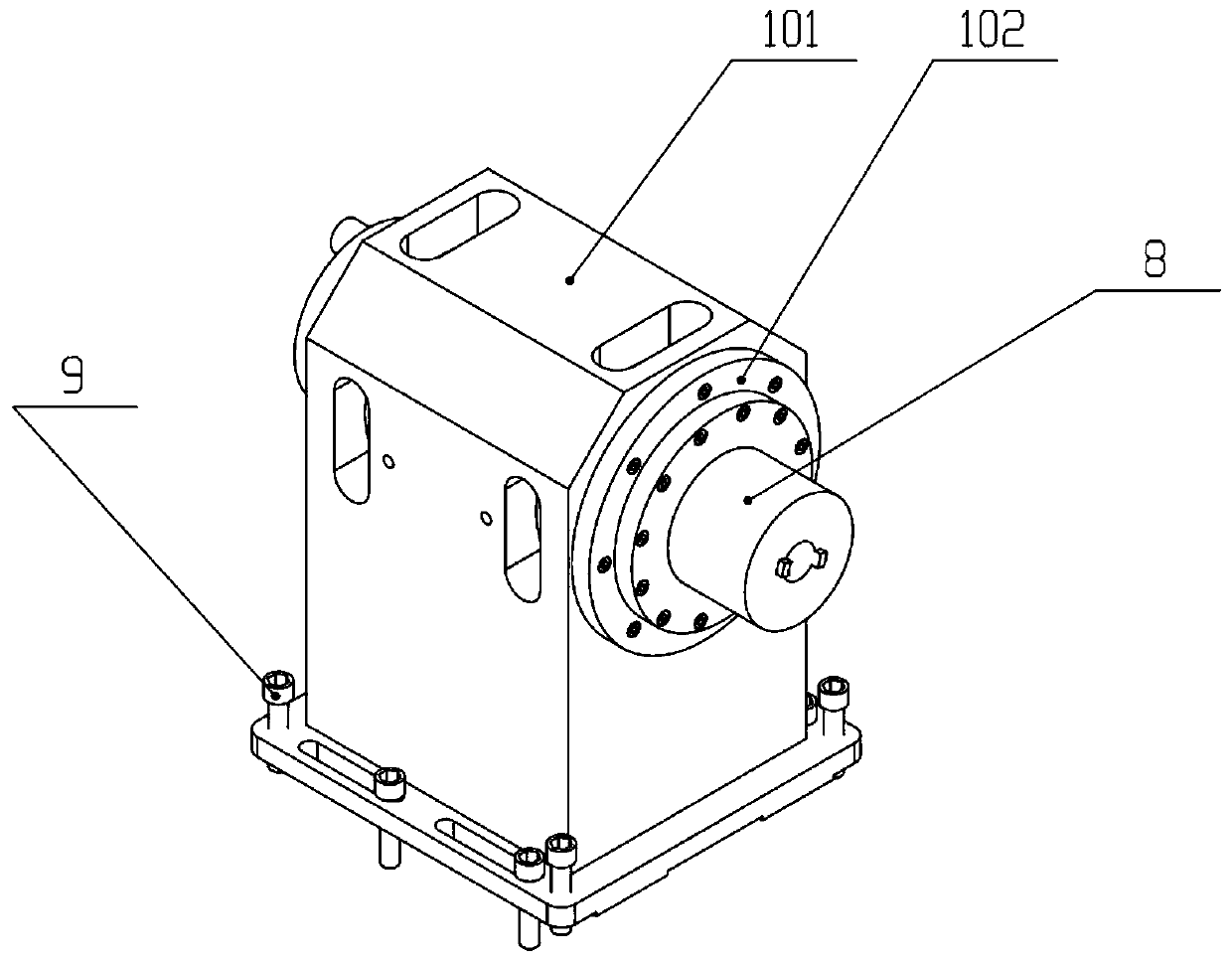

[0041] refer to figure 1 , the present invention consists of an electric spindle clamping module 1, a radial force amplitude loading module 2, a radial force average loading module 3, a cutting torque loading module 4, an axial force loading module 5 and a loading unit module 6.

[0042] refer to figure 1 , Figure 8 and Figure 9 , the electric spindle clamping module 1 passes through the spindle support seat 101, the radial force amplitude loading module 2 passes through the electric vibration table 201, the radial force average loading module 3 passes through the average electric cylinder bracket 302, and the cutting torque loading module 4 passes through The base 404 of the dynamometer is fixedly connected to the top of the horizontal iron 7, and the loading unit module 6 is equipped with a simulated tool handle 601. One end of the simulated tool handle 601 is locked and connected with the cutting torque loading module 4 through the bellows coupling 401, and the other O...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com