A horizontal linear motor driven medium and high frequency fatigue testing machine

A fatigue testing machine, linear motor technology, applied in the direction of applying repetitive force/pulse force to test the strength of materials, instruments, measuring devices, etc. , to achieve the effect of easy promotion, safe and reliable performance, simple and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with a specific case in the accompanying drawings.

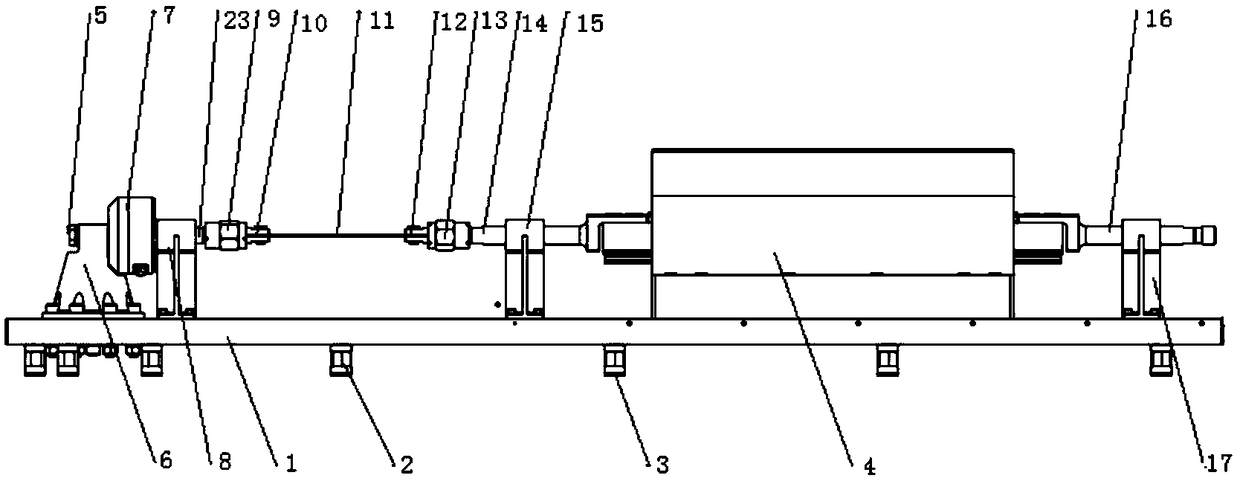

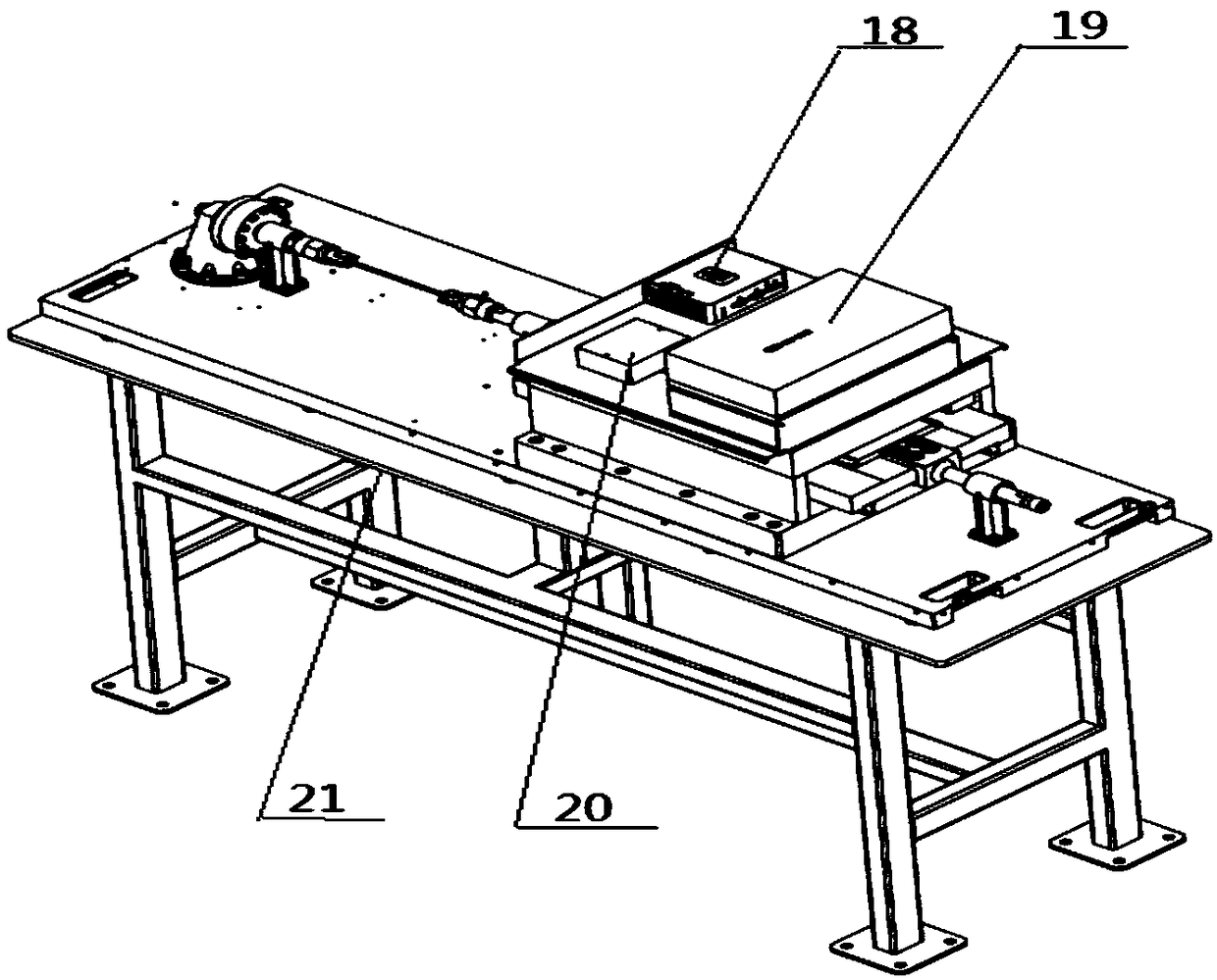

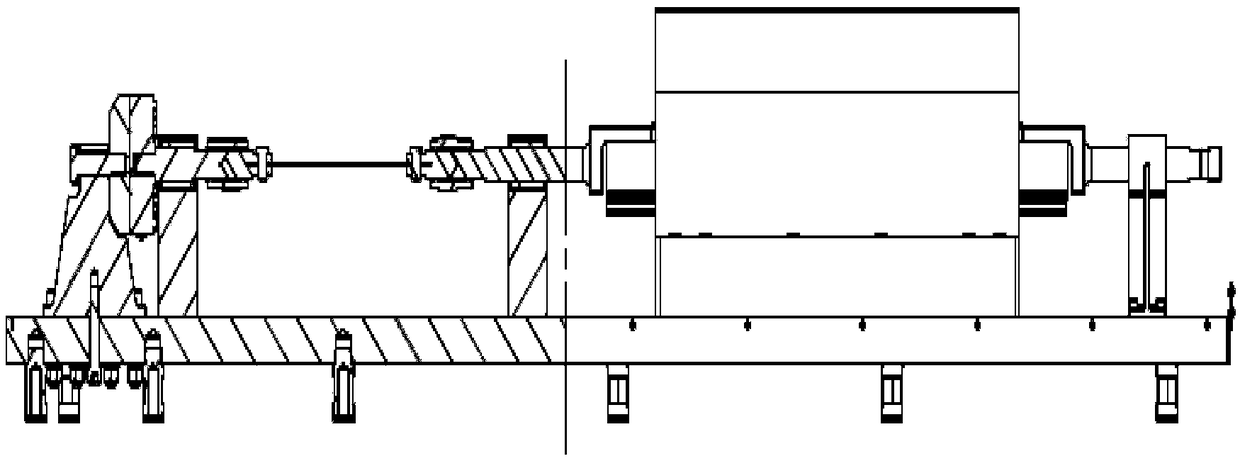

[0036] Such as figure 1 , figure 2 As shown, the high-frequency fatigue testing machine driven by a horizontal linear motor includes a controller 18, a driver 19 and a converter 20; a bottom plate 1, mounting feet 2, damping pads 3, a linear motor 4, connecting screws 5, a sensor seat 6, Force sensor 7, sensor support 8, chucks 10 and 12, specimen 11, clamp lock nuts 9 and 13, front support 15, connecting rods 14, 16 and 23, rear support 17, special table 21.

[0037] In the horizontal linear drive high-frequency fatigue testing machine: the force sensor 7 and the linear motor 4 are respectively fixed on the left and right ends of the base plate 1, the force sensor 7 is connected to the base plate 1 through the sensor seat 6, and the connecting rod 23 at one end of the force sensor 7 is provided There is a sensor support 8 with a built-i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com