Wind power generation blade device with ice removing capacity

A technology for wind power generation blades and ventilation devices, which is applied to wind turbines, wind energy power generation, wind turbines and other directions that are consistent with the wind direction, and can solve problems that are difficult to apply to large-sized, large pre-curved blades, turbine unit vibration power factor, unfavorable Promotion and popularization and other issues, to achieve the effect of reducing design risk, good versatility and adaptability, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

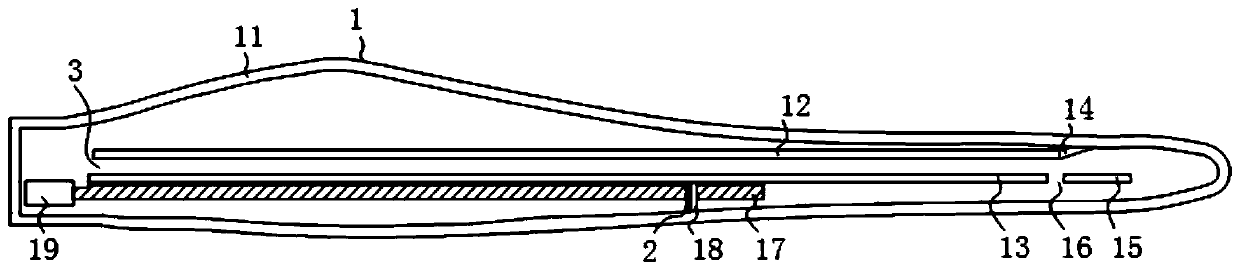

[0022] see figure 1 , a wind power generation blade device with deicing capability, comprising a wind power generation blade 1 and a leading edge air adjustment mechanism 2, the leading edge air adjustment mechanism 2 is installed in the wind power generation blade 1.

[0023] see figure 1 The wind power generation blade 1 includes a blade shell 11, a trailing edge web 12 is installed on the top of the inner wall of the blade shell 11, and a leading edge web 13 is installed on the inner wall of the blade shell 11 and below the trailing edge web 12, The blade web cavity 3 is formed between the trailing edge web 12 and the leading edge web 13, and the trailing edge windshield 14 is installed on the right side of the trailing edge web 12, and the trailing edge windshield 14 is close to the blade shell 11. One side is fixedly installed with the blade shell 11, and the trailing edge windshield 14 is mainly used to seal the cavity of the trailing edge of the blade, so that the hot ...

Embodiment 2

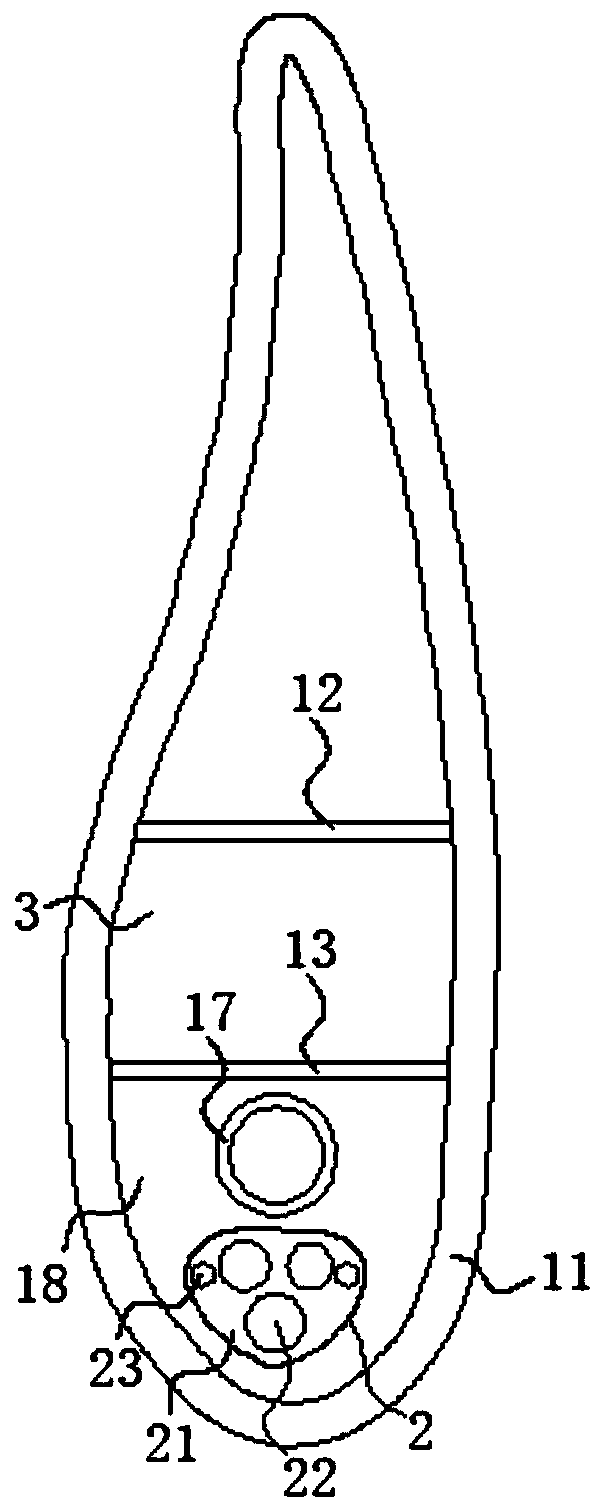

[0026] see image 3 , the front edge adjustment mechanism 2 includes the air hole adjustment pressure plate 21, the air hole adjustment pressure plate 21, the left side of the front edge windshield 18 and the position corresponding to the air hole adjustment pressure plate 21 is provided with a fixed ventilation hole 212 matching it, the wind The left side of the hole adjustment pressure plate 21 is provided with an adjustment bolt 213, and the rear end of the adjustment bolt 213 passes through the air hole adjustment pressure plate 21 and the front edge windshield 18 sequentially from left to right and extends to the inside of the front edge windshield 18 and its thread. Connection, by installing different adjusting bolts 213, the ventilation area of the fixed ventilation hole 212 on the front edge windshield 18 can be adjusted, so as to realize flow and pressure regulation.

Embodiment 3

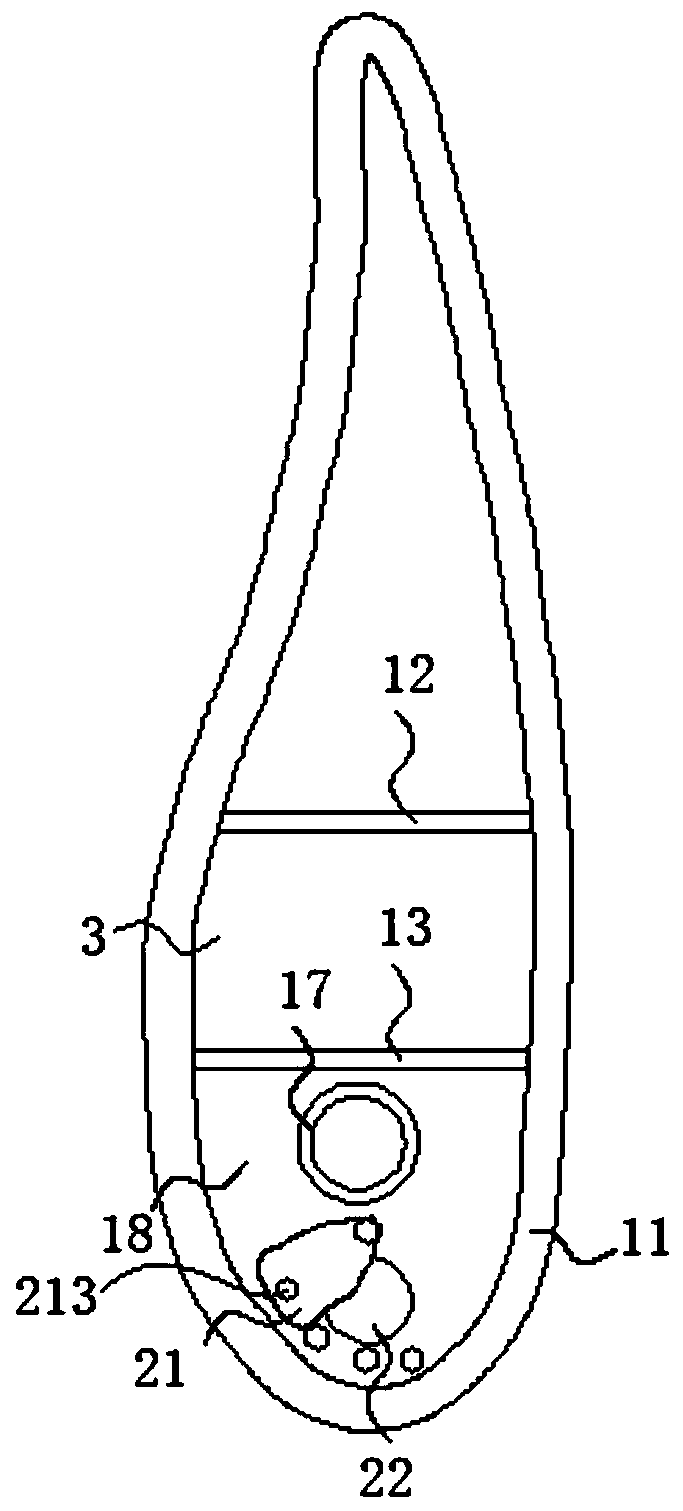

[0028] see Figure 4, the front edge adjustment mechanism 2 includes the air hole adjustment pressure plate 21, the air hole adjustment pressure plate 21, the left side of the front edge windshield 18 and the position corresponding to the air hole adjustment pressure plate 21 is provided with a fixed ventilation hole 212 matching it, the wind A cylinder 214 is installed on the top of the hole adjustment pressure plate 21, and the side of the cylinder 214 close to the front edge windshield 18 is fixedly installed with the front edge windshield 18. The cylinder 214 can drive the air hole adjustment pressure plate 21 to move up and down, thereby making the air hole adjustment The pressing plate 21 can regulate the area of the fixed ventilation hole 212, and by adding a cylinder 214, the air regulating device can realize automatic air regulating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com