Preparation method of monomenthyl ester, and mint cigarette paper and preparation method thereof

A monomenthyl ester and cigarette paper technology, which is applied in the preparation of carboxylate esters, the preparation of organic compounds, and the manufacture of cigars, etc., can solve the problems of aroma loss, high boiling point of menthyl ester, and low volatility, and achieve the reduction of non-target substances. Generate, reduce the generation of harmful components, and release uniform and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

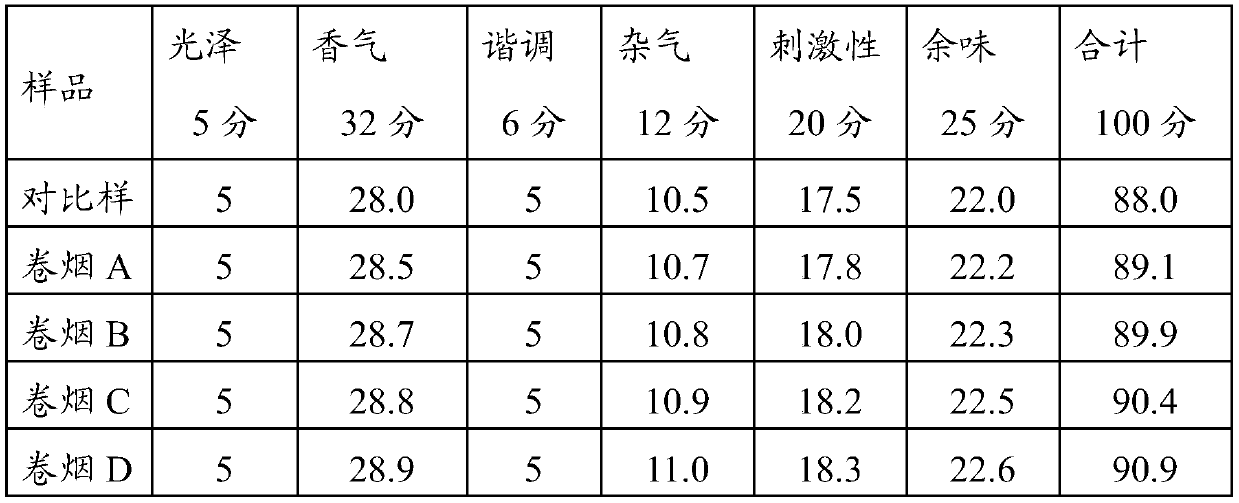

Image

Examples

Embodiment 1

[0029] 15.6 g (0.1 mol) of menthol, 26.1 g (0.07 mol) of isovaleric anhydride, 2.6 g of catalyst DMAP (10% of the mass of isovaleric anhydride) and 150 mL of solvent cyclohexane were successively added into a 250 mL three-necked flask. Magnetic stirring, water bath heating to reflux temperature, reaction 8h. After the reaction was over, the precipitate was removed by filtration, and the filtrate was washed with 5% Na 2 CO 3 Solution extraction, separate the water phase, adjust to pH = 3 with dilute hydrochloric acid, then extract with ethyl acetate, concentrate to remove the solvent, distill under reduced pressure at 1kPa, collect a light yellow viscous liquid at a temperature range of 110-130°C, which is Menthyl Isovalerate.

[0030] The application provides a preparation method of mint cigarette paper:

[0031] Weigh 0.5 kg of menthyl isovalerate and dissolve it in 5 kg of ethanol, so that the concentration percentage of menthyl isovalerate is 10%.

[0032] Cigarette pap...

Embodiment 2

[0034] 15.6 g (0.1 mol) of menthol, 14.0 g (0.14 mol) of succinic anhydride, 1.4 g of catalyst DMAP (10% of the mass of succinic anhydride) and 150 mL of solvent cyclohexane were successively added into a 250 mL three-necked flask. Magnetic stirring, the water bath was heated to reflux temperature, and reacted for 10h. After the reaction was finished, the precipitate was removed by filtration, and the filtrate was washed with 5% Na 2 CO 3 Solution extraction, separate the water phase, adjust to pH = 3 with dilute hydrochloric acid, then extract with ethyl acetate, concentrate to remove the solvent, distill under reduced pressure at 1kPa, collect a light yellow viscous liquid at a temperature range of 110-130°C, which is Monomenthyl Succinate.

[0035] A kind of preparation of mint type cigarette paper:

[0036] Weigh 1.0 kg of monomenthyl succinate and dissolve it in 10 kg of ethanol, so that the concentration percentage of monomenthyl succinate is 10%.

[0037] Cigarette p...

Embodiment 3

[0040] 15.6g (0.1mol) of menthol, 13.7g (0.12mol) of glutaric anhydride, 1.4g of catalyst DMAP (10% of the mass of succinic anhydride) and 150mL of solvent cyclohexane were successively added into a 250mL three-necked flask. Magnetic stirring, the water bath was heated to reflux temperature, and reacted for 10h. After the reaction was finished, the precipitate was removed by filtration, and the filtrate was washed with 5% Na 2 CO 3 Solution extraction, separate the water phase, adjust to pH = 3 with dilute hydrochloric acid, extract with ethyl acetate, concentrate to remove the solvent, distill under reduced pressure at 1kPa, collect a light yellow viscous liquid at a temperature range of 110-130°C, which is pentadiene Monomenthyl Acid.

[0041] A kind of preparation of mint type cigarette paper:

[0042] Weigh 0.5 kg of monomenthyl glutarate and dissolve it in 10 kg of ethanol, so that the concentration percentage of monomenthyl glutarate is 5%.

[0043] Cigarette paper is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com