Organic fertilizer production method

A technology for organic fertilizers and production methods, applied in the preparation of organic fertilizers, organic fertilizers, fertilizer mixtures, etc., can solve the problems of low number of effective viable bacteria, unsatisfactory effects of organic fertilizers, and inactivation, etc., and achieve fermentation speed. Fast, improve the negative impact of soil, ensure the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

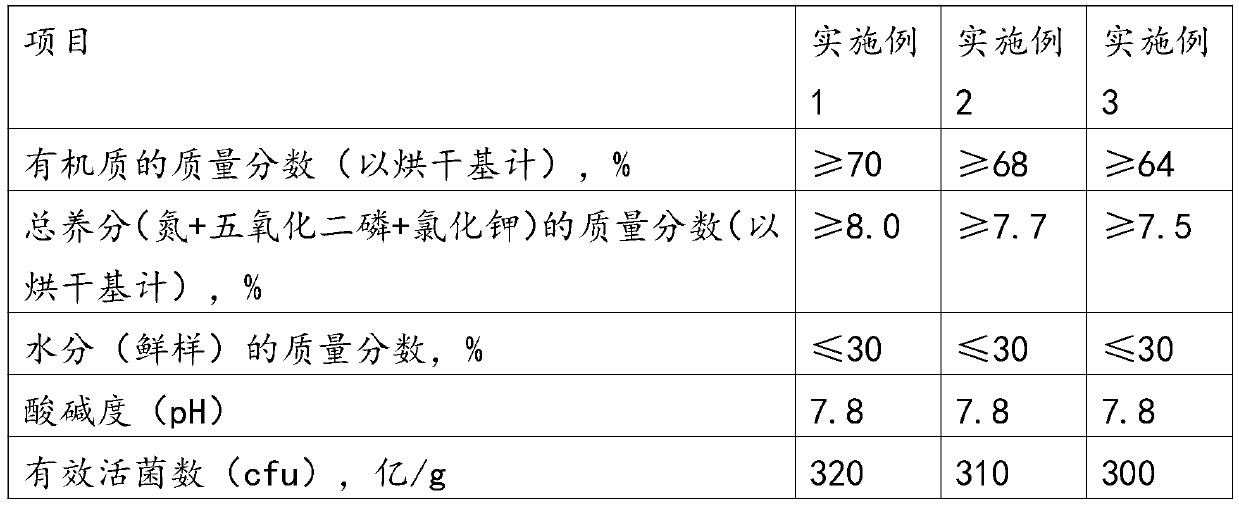

Embodiment 1

[0028] A kind of production method of organic fertilizer, comprises the following steps:

[0029] Sterilization: pulverize flue-cured tobacco stalks to obtain pulverized raw materials. Since flue-cured tobacco stalks are long and rod-shaped, it is inconvenient to mix and adjust the fermentation parameters. Therefore, the collected raw materials need to be sent to a pulverizer to be crushed into a state of uniform size and texture, so that they can participate in subsequent production. The working condition of the pulverizer and the particle size and uniformity of the pulverized material are very important. The particle size of the pulverized raw material is controlled to 20mm. The pulverization effect has a great impact on the subsequent mixing of microbial agents and the mixing of materials in primary fermentation and secondary fermentation. have a direct impact. In the pulverization step, the dust and other substances produced by the pulverization of flue-cured tobacco stal...

Embodiment 2

[0035] A kind of production method of organic fertilizer, comprises the following steps:

[0036] Sterilization: pulverize flue-cured tobacco stalks to obtain pulverized raw materials. Since flue-cured tobacco stalks are long and rod-shaped, it is inconvenient to mix and adjust the fermentation parameters. Therefore, the collected raw materials need to be sent to a pulverizer to be crushed into a state of uniform size and texture, so that they can participate in subsequent production. The working condition of the pulverizer and the particle size and uniformity of the pulverized material are very important. The particle size of the pulverized raw material is controlled to 20mm. The pulverization effect has a great impact on the subsequent mixing of microbial agents and the mixing of materials in primary fermentation and secondary fermentation. have a direct impact. In the crushing step, the dust and other substances produced by the crushing of flue-cured tobacco stalks will be...

Embodiment 3

[0042] A kind of production method of organic fertilizer, comprises the following steps:

[0043] Sterilization: pulverize flue-cured tobacco stalks to obtain pulverized raw materials. Since flue-cured tobacco stalks are long and rod-shaped, it is inconvenient to mix and adjust the fermentation parameters. Therefore, the collected raw materials need to be sent to a pulverizer to be crushed into a state of uniform size and texture, so that they can participate in subsequent production. The working condition of the pulverizer and the particle size and uniformity of the pulverized material are very important. The particle size of the pulverized raw material is controlled to 20mm. The pulverization effect has a great impact on the subsequent mixing of microbial agents and the mixing of materials in primary fermentation and secondary fermentation. have a direct impact. In the crushing step, the dust and other substances produced by the crushing of flue-cured tobacco stalks will be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com