Anti-abrasion corrugated box processing equipment

A technology for corrugated boxes and processing equipment, used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve problems such as affecting cutting effect and corrugated box offset, increase the scope of use, ensure stable reliability, and avoid damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

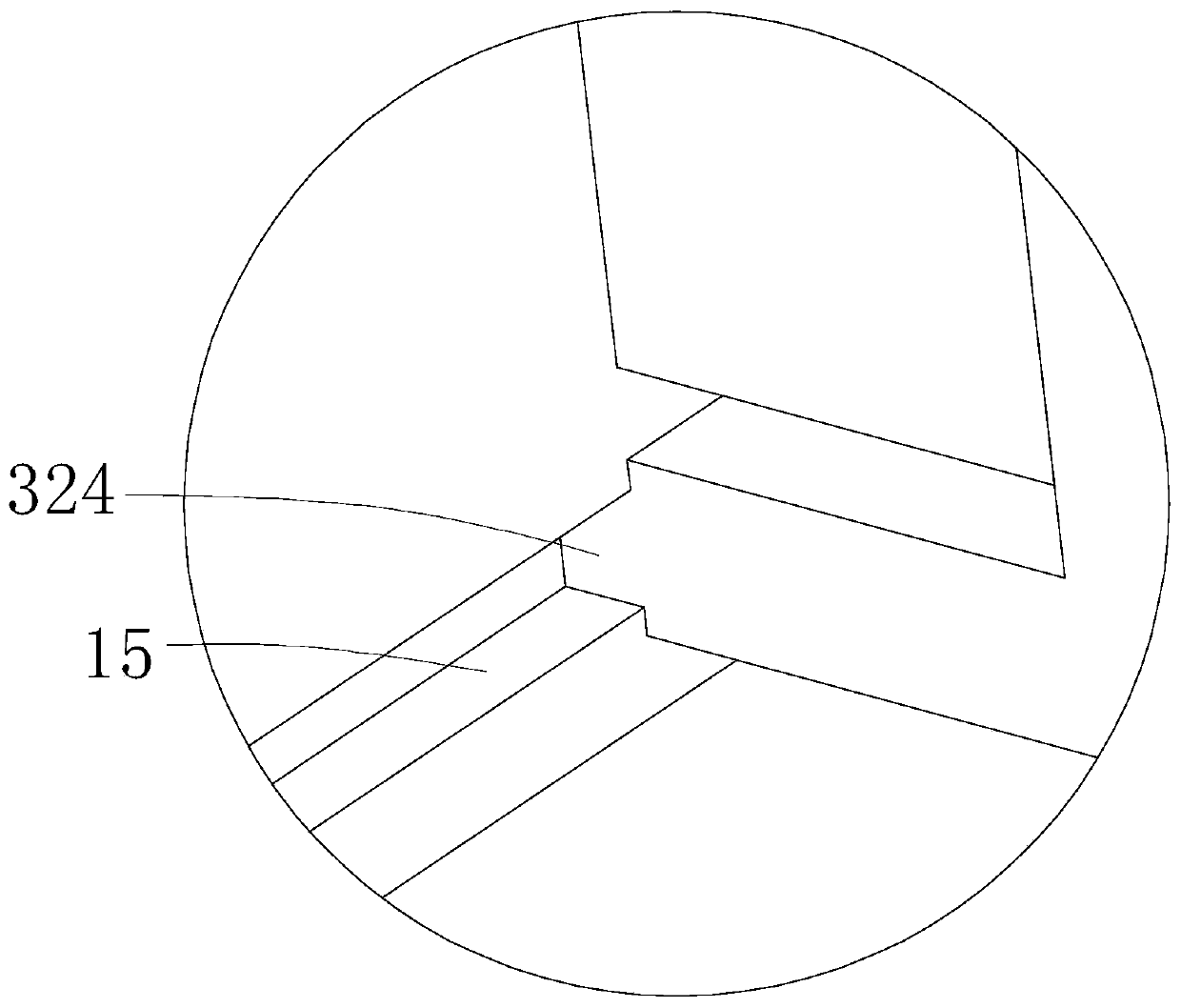

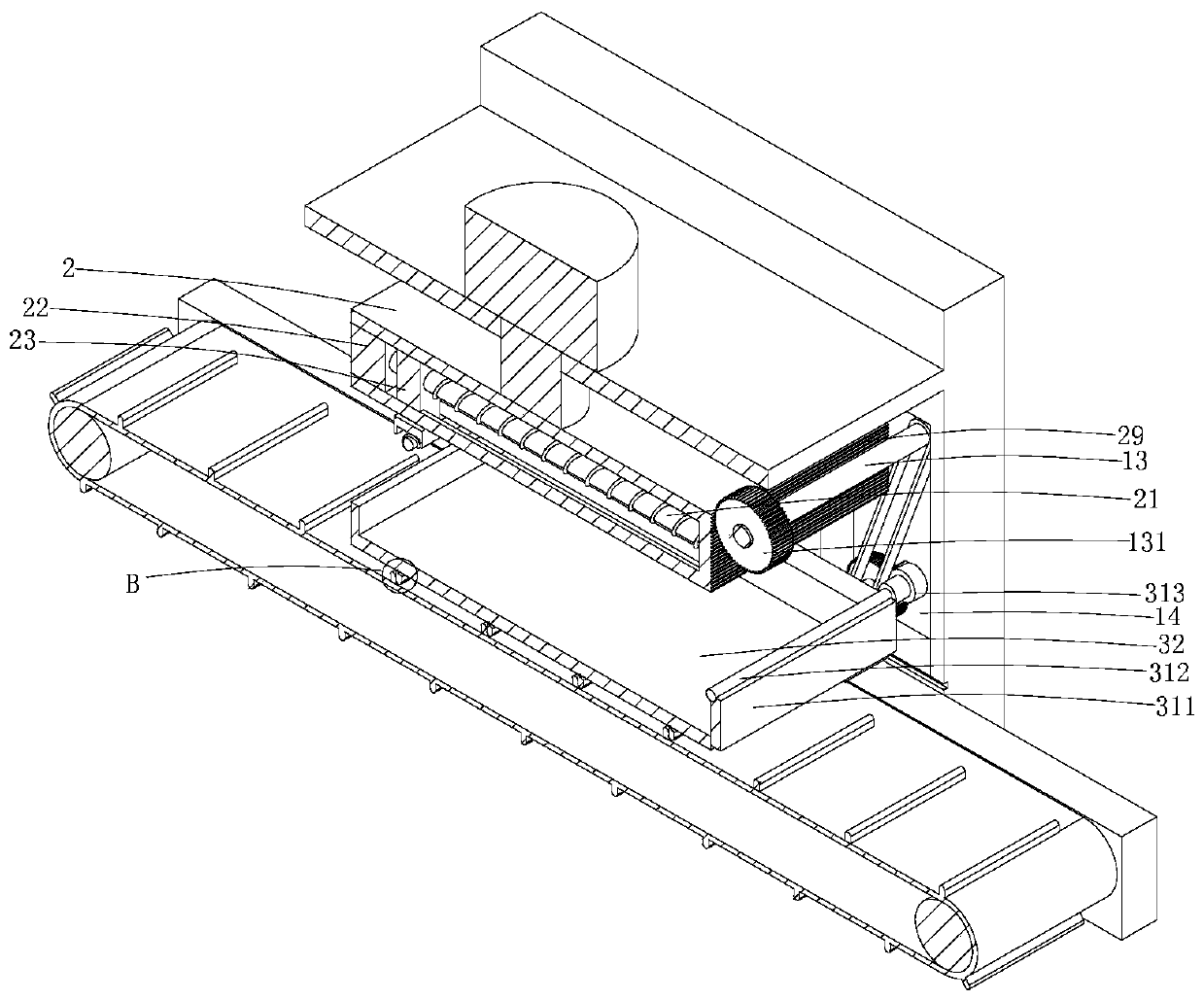

[0024] like Figure 1-9 As shown, a wear-resistant corrugated box processing equipment includes a fixed frame 1, a vertically movable support plate 2 and a transmission member 11 for conveying processed corrugated cardboard; the fixed frame 1 is provided with a support plate for driving 2. The first driver 12 that moves vertically. The bottom of the support plate 2 is provided with a processing device for slitting corrugated cardboard. The bottom of the support plate 2 is fixed with a limit frame for stabilizing corrugated cardboard boxes. 31. The conveying member 11 is provided with a movable feeding bottom plate 32. Through the setting of the above-mentioned structure, the above-mentioned corrugated box can be effectively slit on the corrugated box through the above-mentioned processing device, and can be cut through the limit frame and the feeding bottom plate. Realize the support and limit of the corrugated box, so that when the corrugated box is pressed, it can be kept st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com