Climbing robot with sand blasting structure

A robot and sandblasting technology, applied in the field of climbing robots, can solve the problems affecting the normal operation of the ship, the long period of time for changing the ship's paint skin, and the low efficiency of the old paint skin, so as to achieve the convenience of normal operation, convenient replacement, and reduce the loss of pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

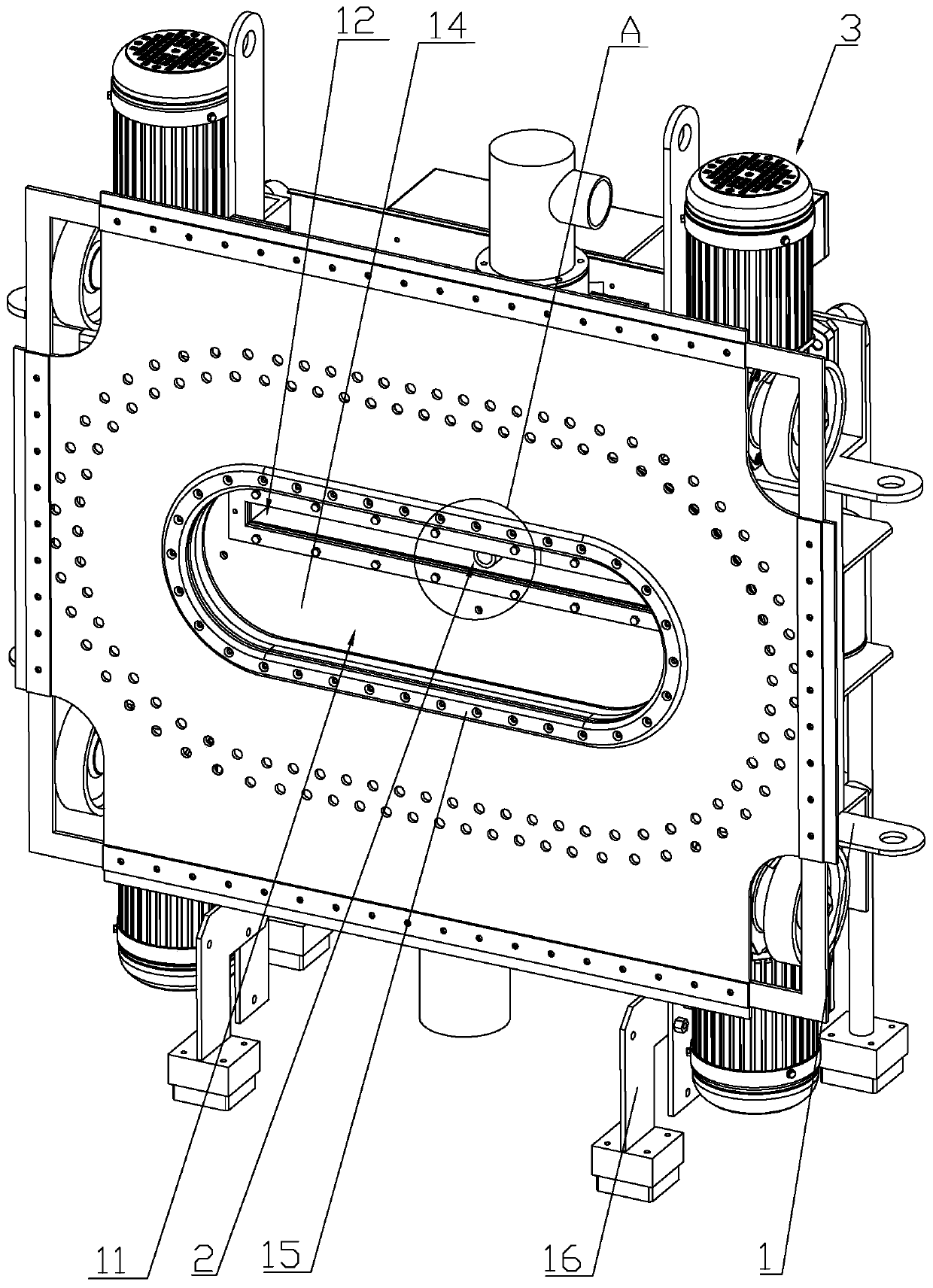

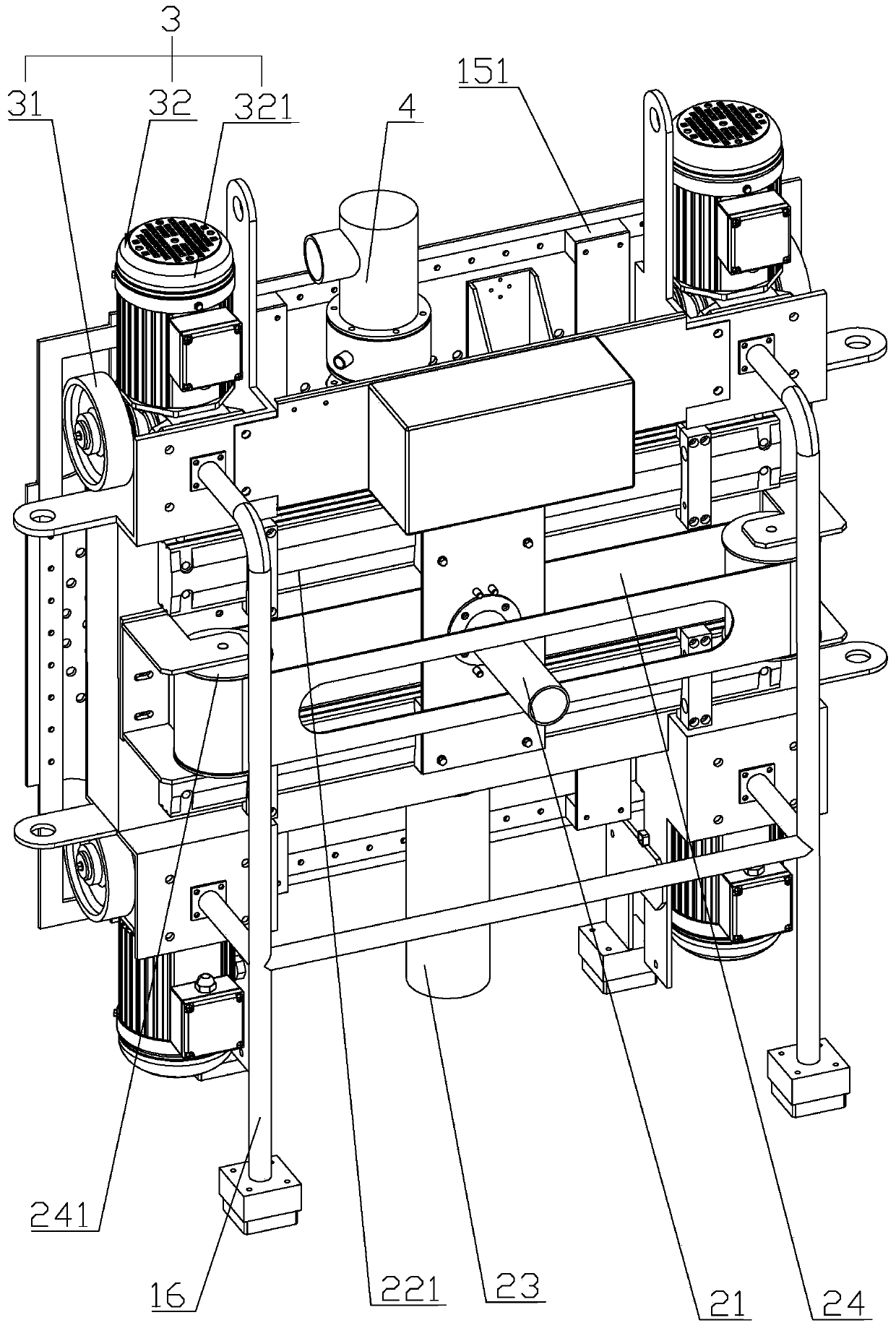

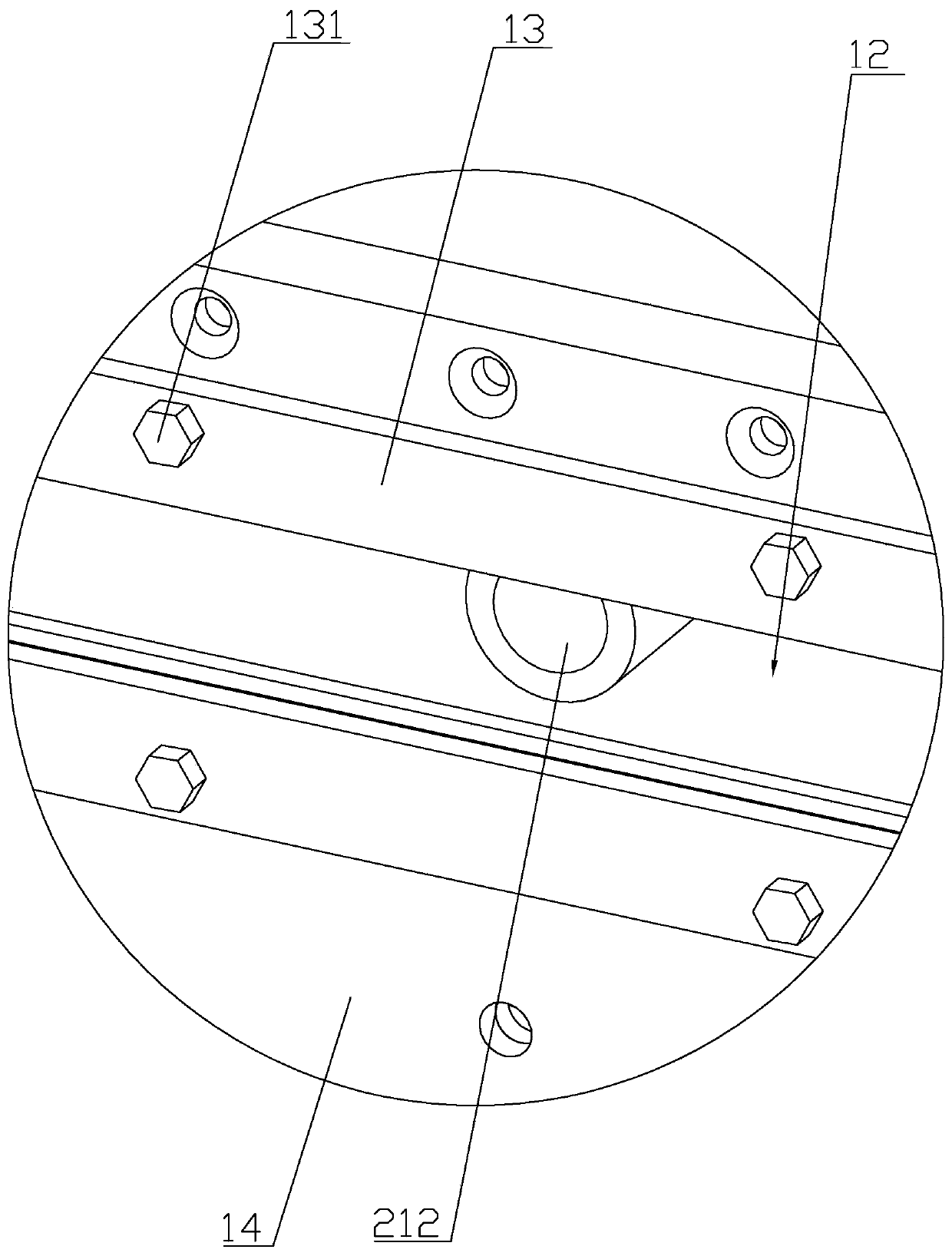

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0036] refer to figure 1 , is a climbing robot with a sandblasting structure disclosed in the present invention, including a body 1, the body 1 is square, and the bottom of the body 1 is provided with four support feet 16, and the four support feet 16 are arranged in a trapezoidal shape, and all pass through The screws are fixed to the body 1 to facilitate the placement of the body 1 . When the body 1 breaks away from the surface of the ship and falls on the ground, the support feet 16 support the body 1, thereby reducing the workload of maintenance personnel for manual support. The body 1 is provided with a climbing mechanism 3 and a sandblasting mechanism 2. The climbing mechanism 3 is used to move the body 1 along the place to be polished of the ship to facilitate the sandblasting mechanism 2 to sandblast and polish the surface of the ship, thereby removi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com