Machine for cleaning and disinfecting dirt on filter screen of dust removing equipment

A technology of dust removal equipment and filter screen, applied in the field of dust removal equipment filter screen dirt cleaning and disinfection machine, can solve the problems of dust inhalation into the body, poor brushing force, and filter screen not fixed, so as to reduce the probability of dust inhalation and the use of force. Uniform and stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

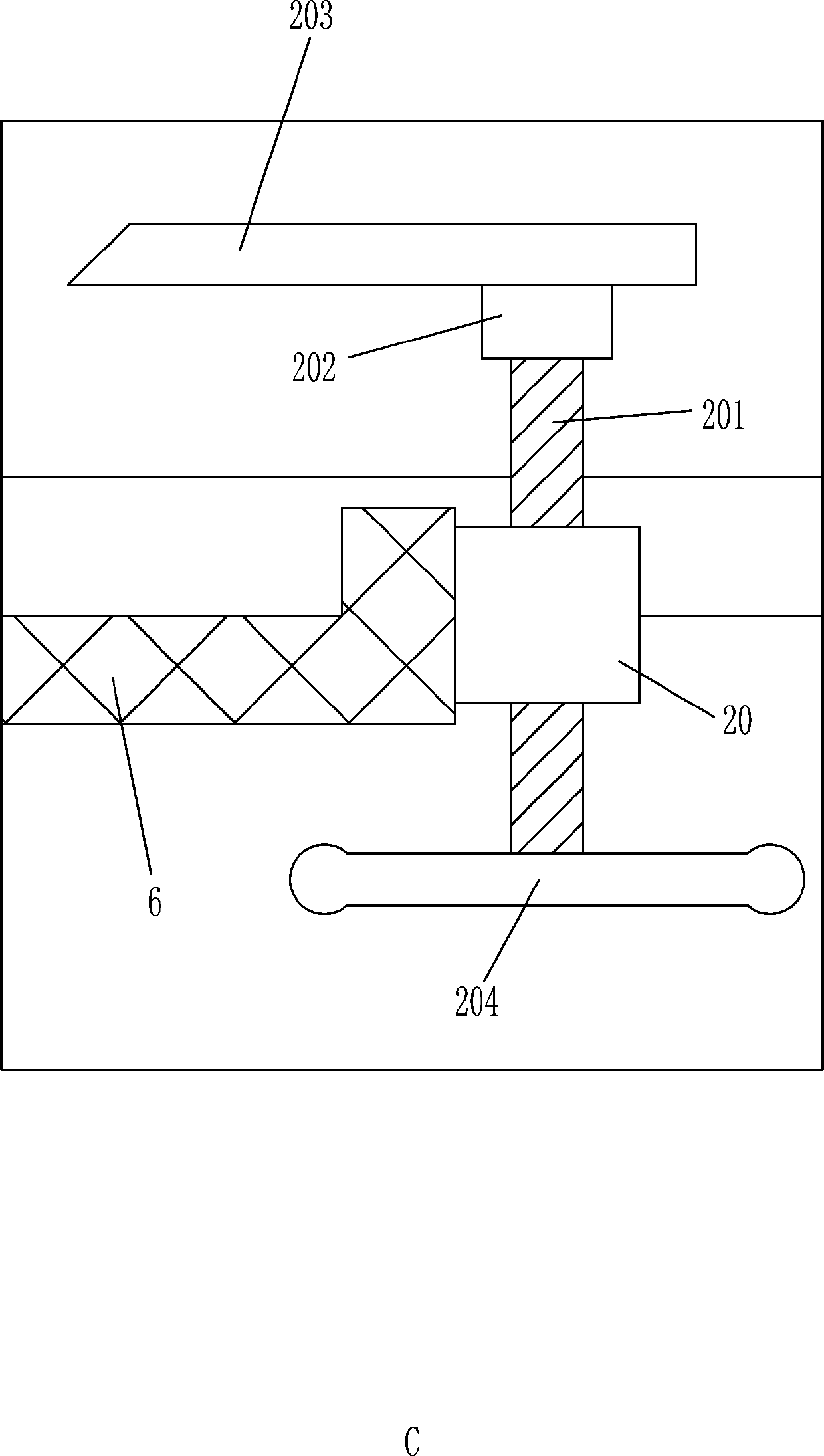

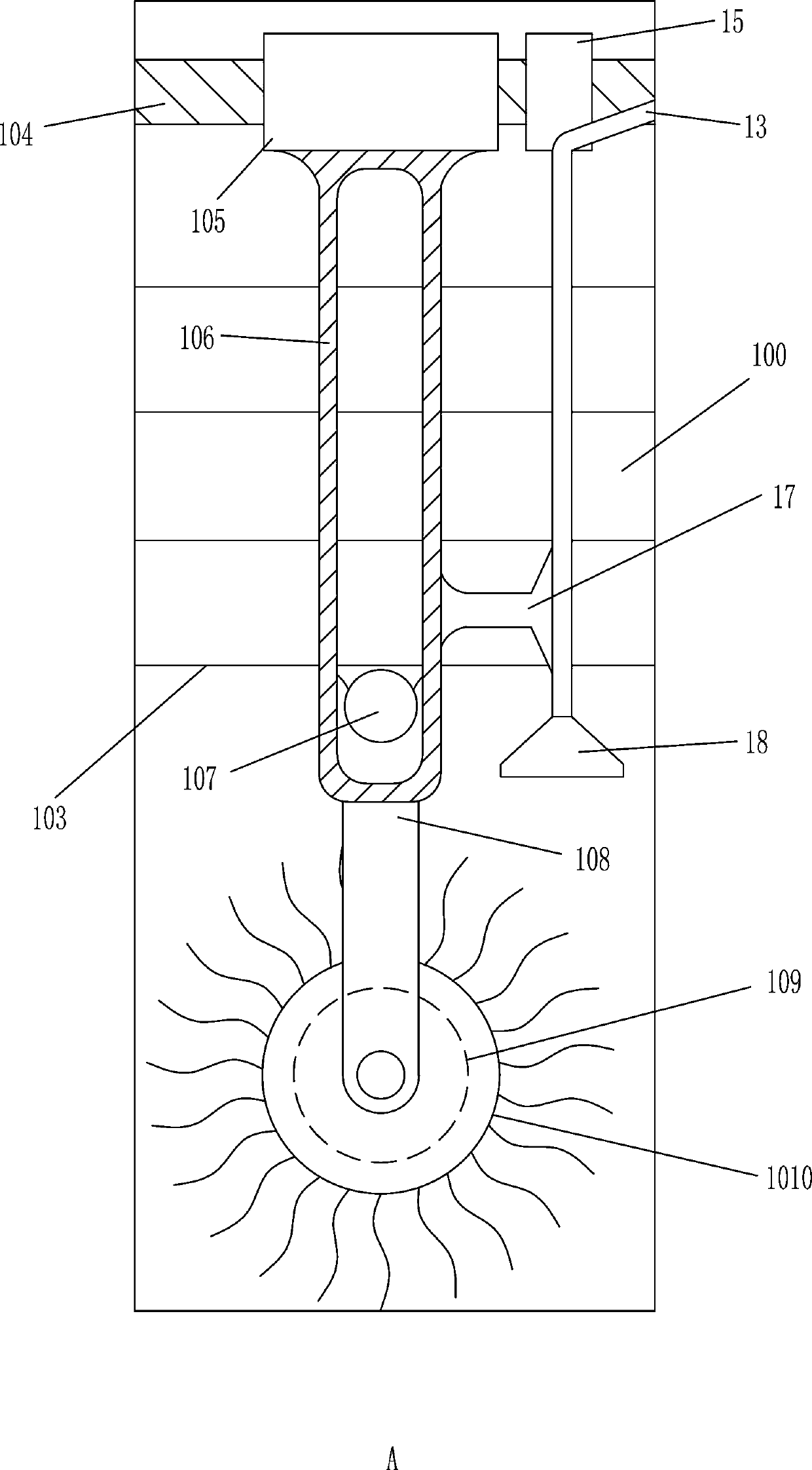

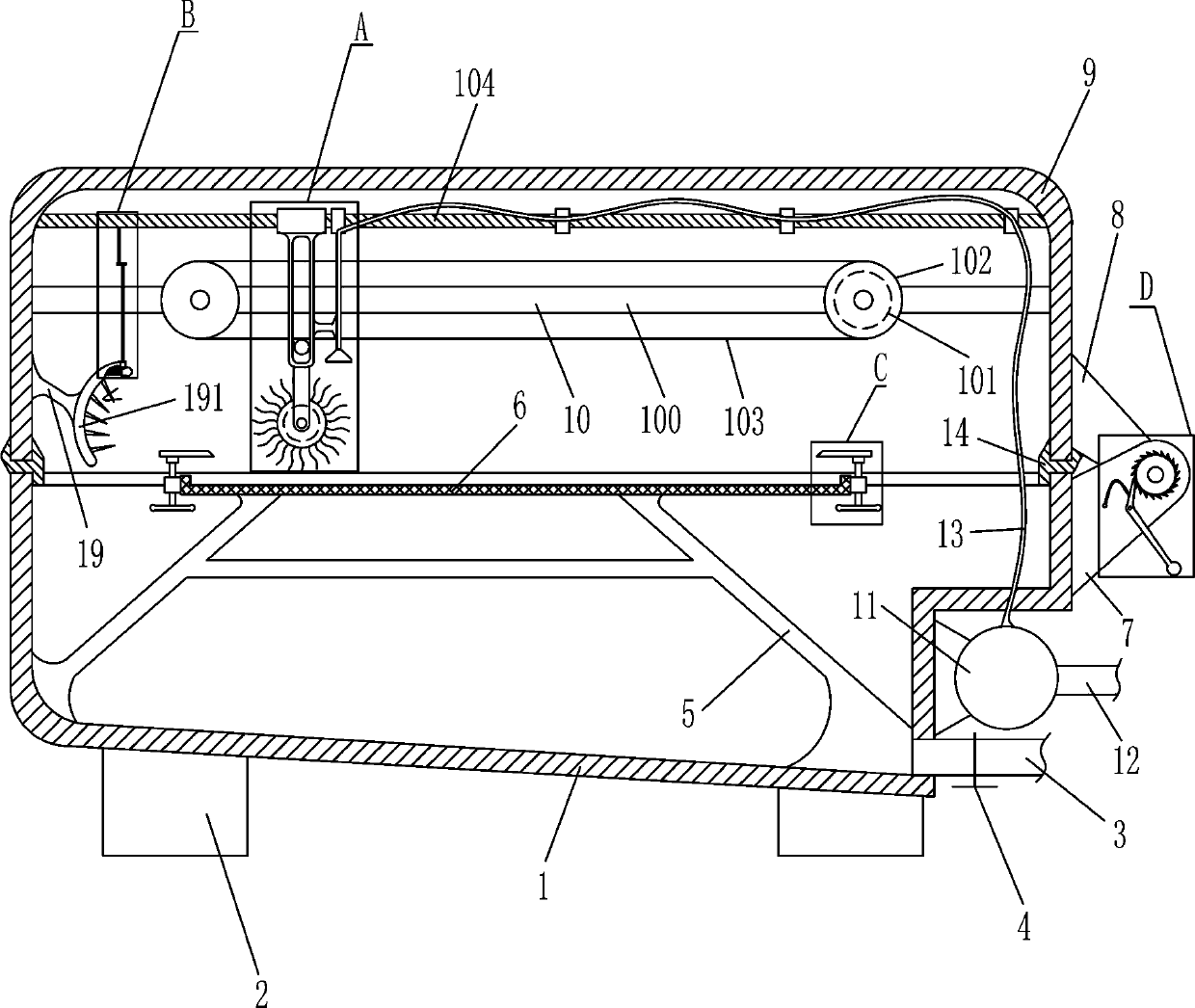

[0018] A dust removal equipment filter dirt cleaning and disinfection machine, such as Figure 1-5 As shown, it includes a first frame body 1, a foot pad 2, a sewage pipe 3, a valve 4, a bracket 5, a screen 6, a first connecting plate 7, a second connecting plate 8, a second frame body 9, and a cleaning device 10 , liquid pump 11, feed pipe 12, nozzle pipe 13, sealing ring 14, sliding ring 15, rotating shaft 16, fixed rod 17 and nozzle 18, and the left and right sides of the bottom of the first frame body 1 are provided with two foot pads of different sizes 2. The first frame body 1 is connected to the foot pad 2 by welding. The lower part of the right side of the first frame body 1 is provided with a sewage pipe 3. The sewage pipe 3 is provided with a valve 4. The valve 4 is located at the bottom of the first frame body 1. On the right, the first frame body 1 is provided with a bracket 5, the bracket 5 is located behind the sewage pipe 3, the top of the bracket 5 is provided ...

Embodiment 2

[0020] A dust removal equipment filter dirt cleaning and disinfection machine, such as Figure 1-5 As shown, it includes a first frame body 1, a foot pad 2, a sewage pipe 3, a valve 4, a bracket 5, a screen 6, a first connecting plate 7, a second connecting plate 8, a second frame body 9, and a cleaning device 10 , liquid pump 11, feed pipe 12, nozzle pipe 13, sealing ring 14, sliding ring 15, rotating shaft 16, fixed rod 17 and nozzle 18, and the left and right sides of the bottom of the first frame body 1 are provided with two foot pads of different sizes 2. The lower part of the right side of the first frame body 1 is provided with a sewage pipe 3, and a valve 4 is arranged on the sewage pipe 3. The valve 4 is located on the right side of the first frame body 1. The first frame body 1 is provided with a bracket 5, and the bracket 5 Located behind the sewage pipe 3, the top of the bracket 5 is provided with a screen 6, the top of the first frame body 1 is provided with a sea...

Embodiment 3

[0023] A dust removal equipment filter dirt cleaning and disinfection machine, such as Figure 1-5 As shown, it includes a first frame body 1, a foot pad 2, a sewage pipe 3, a valve 4, a bracket 5, a screen 6, a first connecting plate 7, a second connecting plate 8, a second frame body 9, and a cleaning device 10 , liquid pump 11, feed pipe 12, nozzle pipe 13, sealing ring 14, sliding ring 15, rotating shaft 16, fixed rod 17 and nozzle 18, and the left and right sides of the bottom of the first frame body 1 are provided with two foot pads of different sizes 2. The lower part of the right side of the first frame body 1 is provided with a sewage pipe 3, and a valve 4 is arranged on the sewage pipe 3. The valve 4 is located on the right side of the first frame body 1. The first frame body 1 is provided with a bracket 5, and the bracket 5 Located behind the sewage pipe 3, the top of the bracket 5 is provided with a screen 6, the top of the first frame body 1 is provided with a sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com