Electrical automatic intelligent dust removal system

A technology of electrical automation and dust removal system, which is applied in the direction of dust removal, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as high power consumption, a large amount of smoke, dust particles, harmful gases, and human discomfort, so as to ensure cleaning efficiency. , easy to reuse, to ensure the effect of closed space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0031] It should be understood that terms such as "having", "comprising" and "including" used herein do not exclude the presence or addition of one or more other elements or combinations thereof.

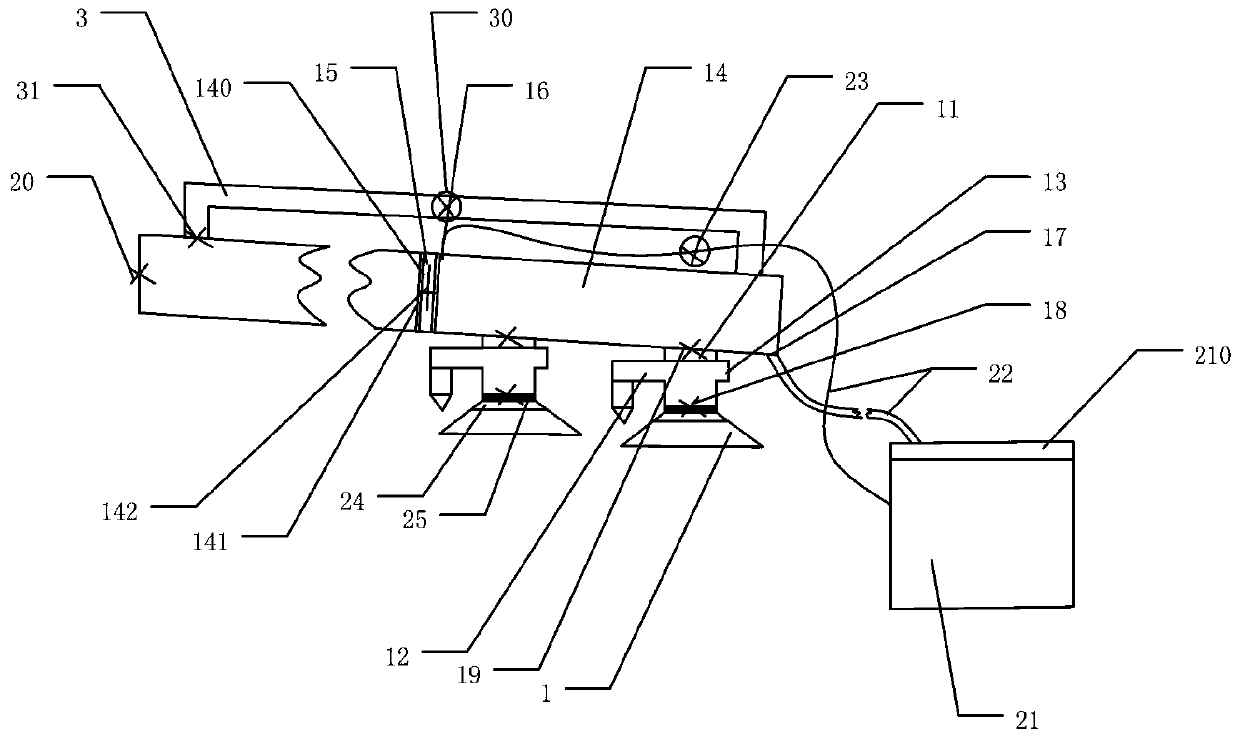

[0032] like figure 1 and Figure 4 As shown, the present invention provides a kind of electrical automatic intelligent dust removal system, comprising:

[0033] Dust removal device, which includes:

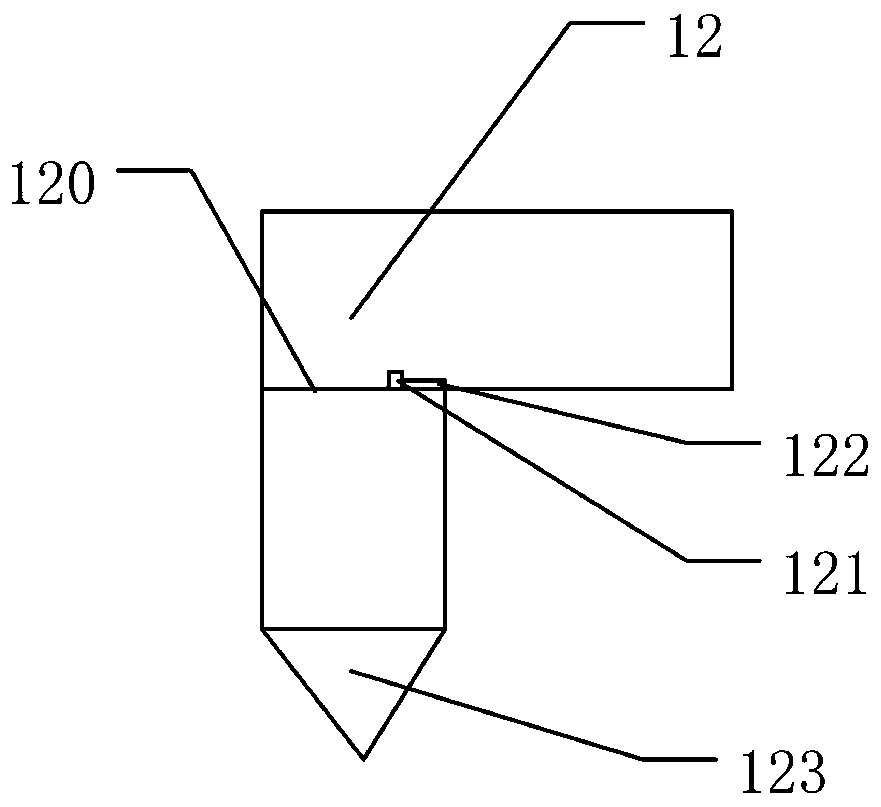

[0034] A plurality of dust removal covers 1 are arranged in the dust removal area, and dust suction devices are arranged in the dust removal covers 1 .

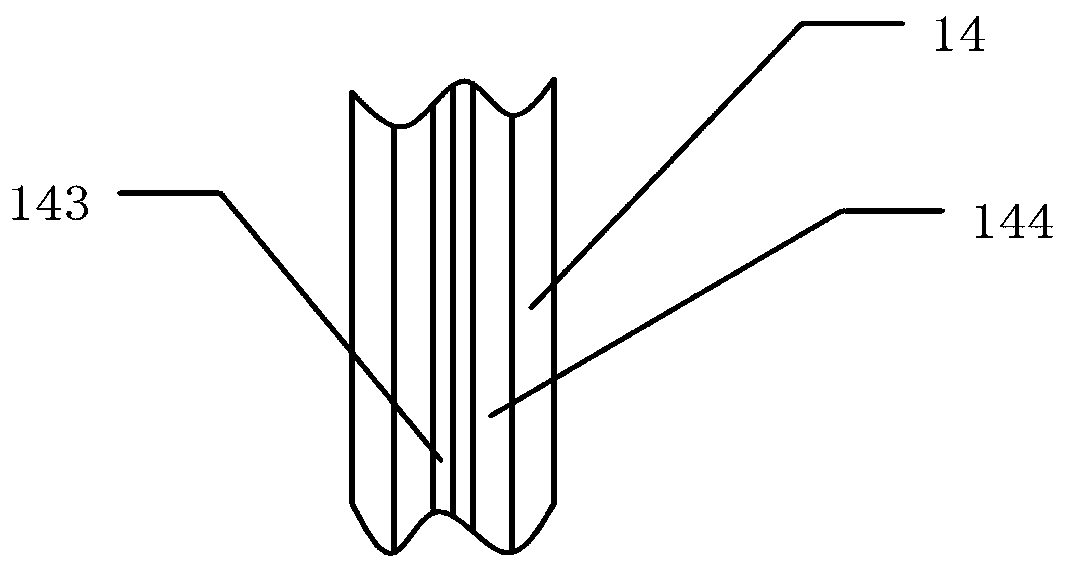

[0035] A plurality of first pipelines 10, which are respectively connected to the dust removal cover 1 correspondingly, a first filter device 11 is arranged at the air outlet of the first pipeline 10, and one side of the first pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com