Tencha and processing technology thereof

A processing technology and technology of grinding tea, which is applied in the field of grinding tea and its processing technology, can solve the problems of unstable chlorophyll and color influence of finished grinding tea, and achieve the effect of high chlorophyll content, difficult light, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

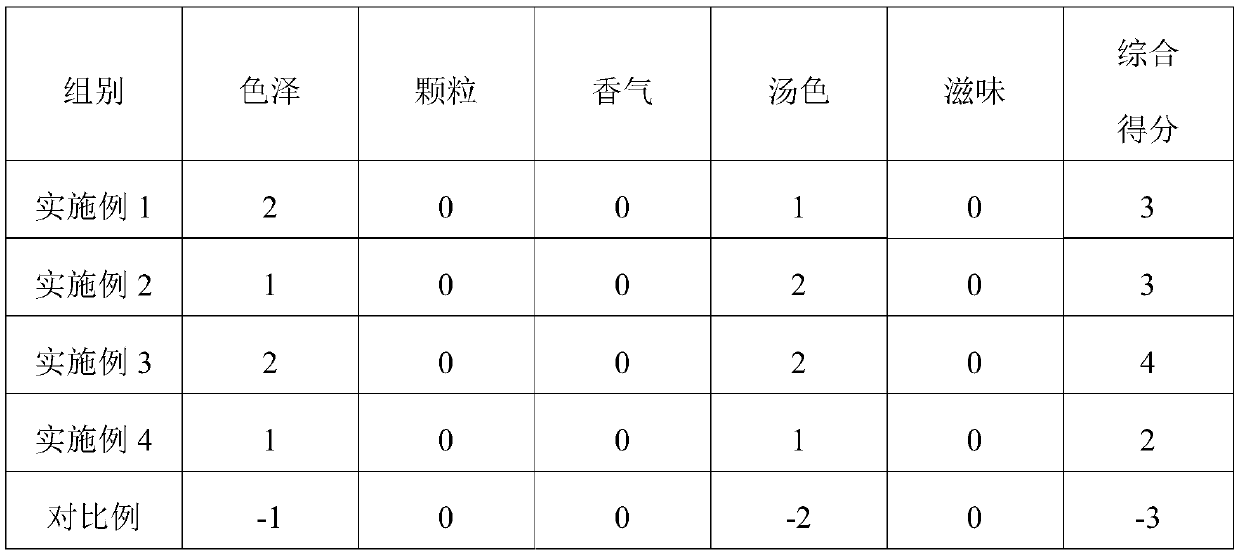

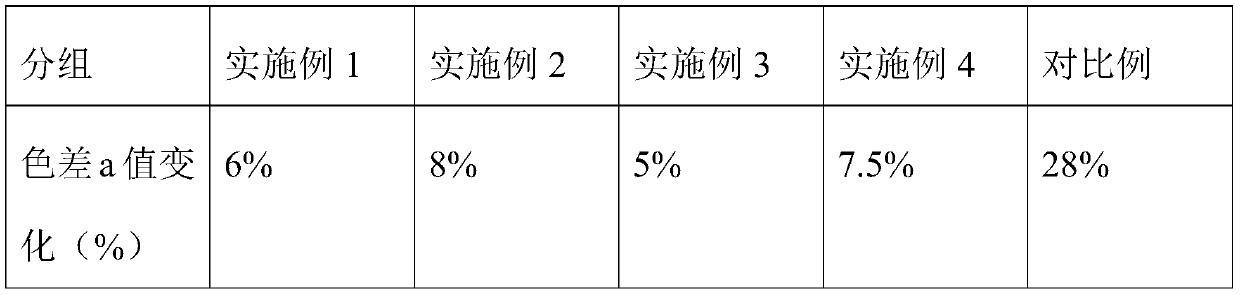

Examples

Embodiment 1

[0035] A kind of milled tea processing technology, operation is as follows:

[0036] Picking of fresh leaves: pick fresh leaves with 1 bud and 4-6 leaves from the tea tree (China Tea 302) that has been shaded for 24 days, and blow cold wind before steaming to keep the fresh leaves fresh;

[0037] Chopping and grading fresh leaves: cutting fresh leaves into 5cm fragments, and separating and removing old stalks and old leaves through a vibrating sieve;

[0038] Steam cleaning of fresh leaves: steam cleaning of fresh leaves with a steam cleaning machine, steam flow rate 90kg / h, cylinder inclination angle 14°, cylinder rotation speed 25rpm, stirring speed 250rpm, steam pressure 0.01MPa, temperature 100°C , the finishing time is 30S;

[0039] Hot air dehumidification: use a hot air dehumidifier to dehumidify the green leaves obtained by steaming fresh leaves until the moisture content is 85%, and the temperature of the hot air is 30°C;

[0040] Stirring: the green leaves after th...

Embodiment 2

[0050] A kind of milled tea processing technology, operation is as follows:

[0051] Picking of fresh leaves: pick fresh leaves with 1 bud and 4-6 leaves from the tea tree (Aolu) that has been shaded for 15 days, and refrigerate them before steaming to keep the fresh leaves fresh;

[0052]Chopping and grading fresh leaves: cutting fresh leaves into 10cm fragments, separating and removing old stalks and old leaves through a vibrating sieve;

[0053] Steam cleaning of fresh leaves: Use a steam cleaning machine to steam green leaves, with a steam flow rate of 100kg / h, a cylinder inclination angle of 10°, a cylinder rotation speed of 30rpm, a stirring speed of 500rpm, a steam pressure of 0.05MPa, and a temperature of 130°C , the finishing time is 5S;

[0054] Hot air dehumidification: use a hot air dehumidifier to dehumidify the green leaves obtained by steaming fresh leaves until the moisture content is 62%, and the temperature of the hot air is 40°C;

[0055] Stir: the green l...

Embodiment 3

[0065] A kind of milled tea processing technology, operation is as follows:

[0066] Picking of fresh leaves: pick fresh leaves with 1 bud and 4-6 leaves from the tea tree (Xiaoye Fuding) covered in shade for 20 days, and refrigerate them before steaming to keep the fresh leaves fresh;

[0067] Chopping and grading fresh leaves: cutting fresh leaves into 10cm fragments, separating and removing old stalks and old leaves through a vibrating sieve;

[0068] Fresh leaf steaming: use a steam cleaning machine to steam fresh leaves, the steam flow rate is 120kg / h, the cylinder inclination angle is 12°, the cylinder speed is 40rpm, the stirring speed is 400rpm, the steam pressure is 0.04MPa, and the temperature is 110℃ , the finishing time is 20S;

[0069] Hot air dehumidification: use a hot air dehumidifier to dehumidify the green leaves obtained by steaming fresh leaves until the moisture content is 75%, and the temperature of the hot air is 35°C;

[0070] Stir: the green leaves a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com