Multi-row parallel wiring harness connector

A wire harness connector and connector technology, which is applied in the direction of vehicle connectors and connections where permanent deformation plays a role, can solve problems such as intricate wire harnesses, hidden dangers of automobile safety, and cumbersome operations, so as to improve safety, improve flatness, and improve firmness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

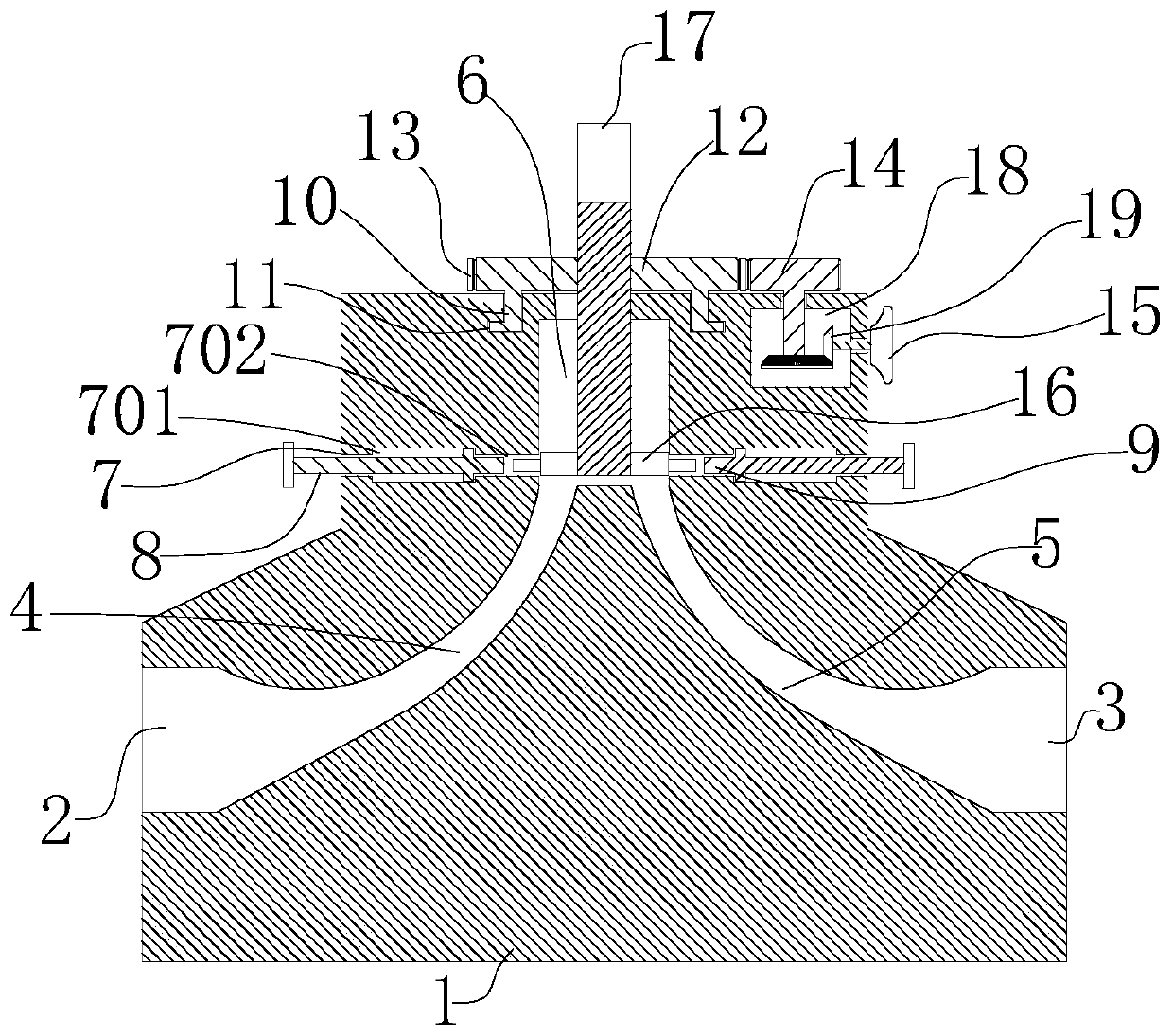

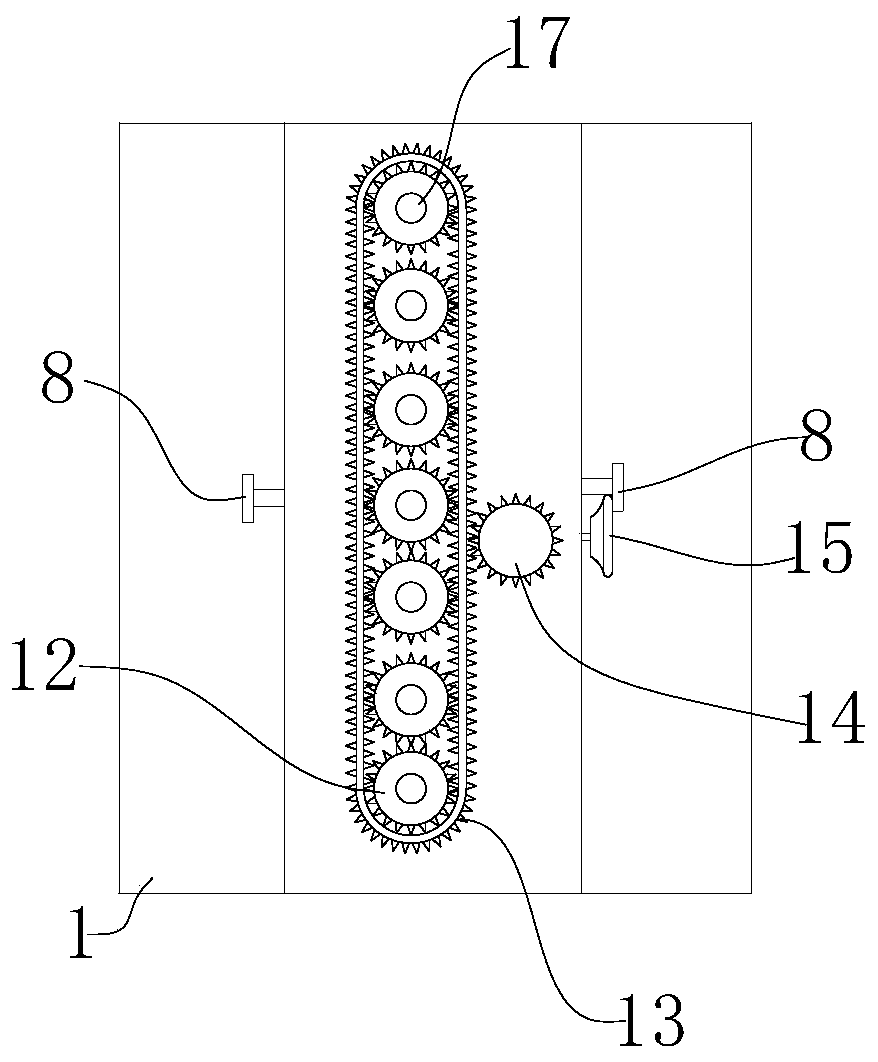

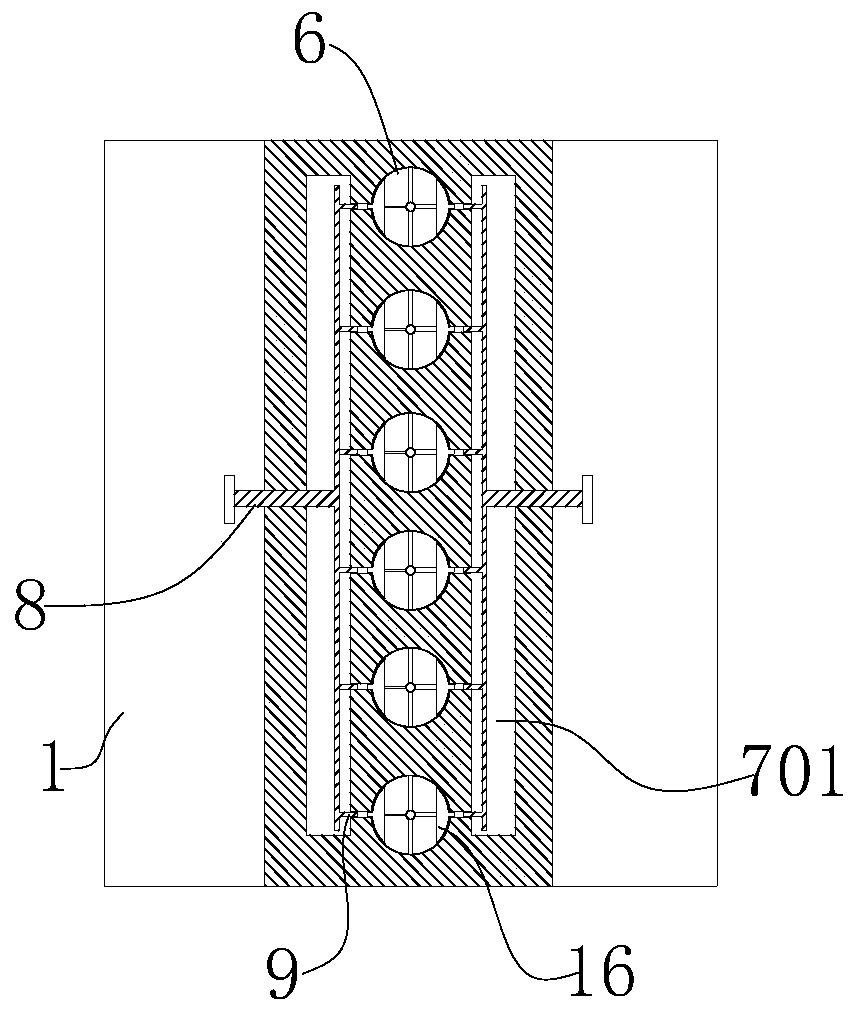

[0037] see Figure 1-6, is a schematic diagram of the overall structure of a multi-row parallel harness connector, including a connector body 1 and a winding cavity 6. The connector body 1 is set in a stepped square block structure, and the top area of the square block is smaller than that of the square block. The area of the bottom end, the left side wall of the connector body 1 is provided with symmetrically distributed first wire harness inlets 2, the inside of the first wire harness inlet 2 is provided with a first wire harness cavity 4, and the top of the first wire harness cavity 4 is connected to the The winding chamber 6 is connected, and the right side wall of the connector body 2 is provided with a second wire harness inlet 3 matching the first wire harness inlet 2, and a second wire harness cavity 5 is provided inside the second wire harness inlet 3, The top of the second harness cavity 5 communicates with the winding cavity 6, which is arranged inside the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com