Forming method for high-precision metal bipolar plate required by fuel cell

A metal bipolar plate and fuel cell technology, applied to fuel cell parts, forming tools, metal processing equipment, etc., can solve the problems of increased manufacturing costs, increased scrap rate, uneven bipolar plate surface, etc., to achieve Reduce molding warpage and stress deformation, reduce production scrap rate, and optimize the effect of molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

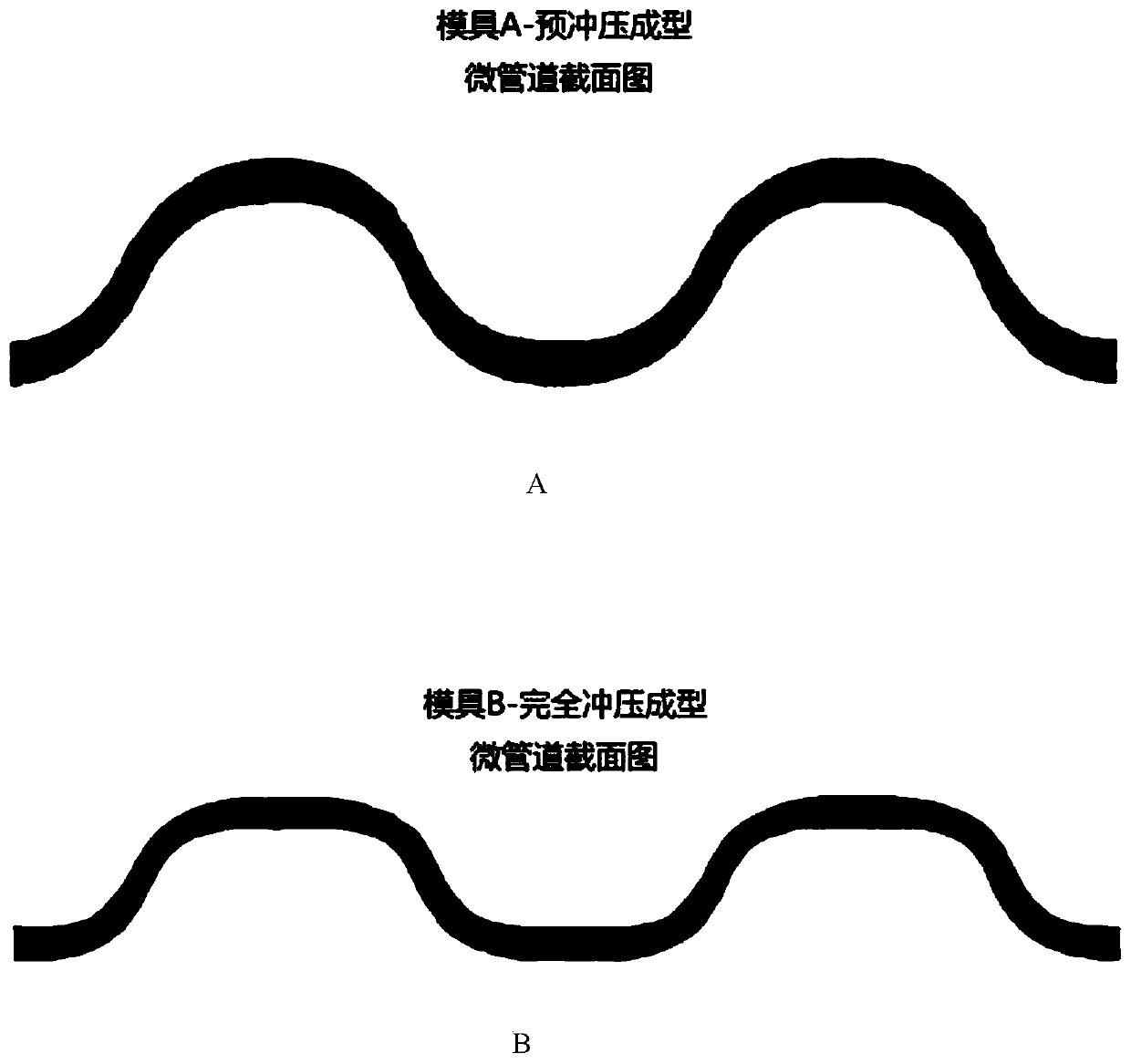

[0059] This embodiment provides a two-step stamping method for preparing a high-precision metal bipolar plate required for a fuel cell. The specific steps are as follows:

[0060] S1, select the raw material of the bipolar plate;

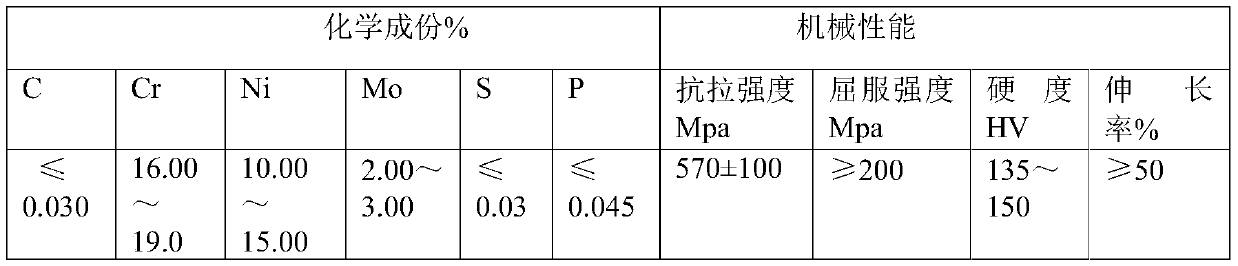

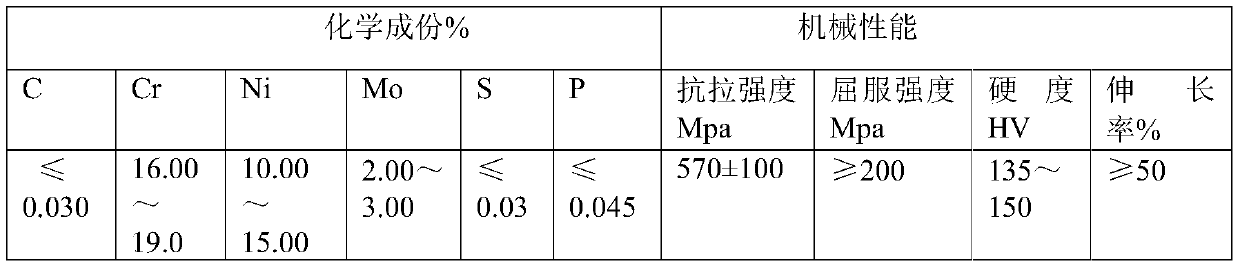

[0061] The selection of raw material plates is the key to manufacturing high-precision metal-based fuel cell bipolar plates. To manufacture high-performance metal-based fuel cell bipolar plates, the molding performance of raw materials must be considered. , Structural ribs and a series of structures, to form such a metal plate, it is necessary to choose moderate hardness, high elongation, and high tensile strength to prevent the plate from cracking. At the same time, as the fuel cell gas flow channel and reaction vessel, the plate material should also have good corrosion resistance, and it can continuously and stably collect current without being oxidized and corroded. The present invention selects an austenitic stainless steel SUS316L with strong ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com