Method and device for determining supporting strength of large-dip-angle fully-mechanized coal mining face

A technology of fully mechanized mining face and support strength, applied in special data processing applications, instruments, electrical digital data processing, etc. problems, to achieve the effect of reducing workload, reducing human intervention, and determining the method is simple and easy to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Hereinafter, the present application will be described in detail with reference to the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

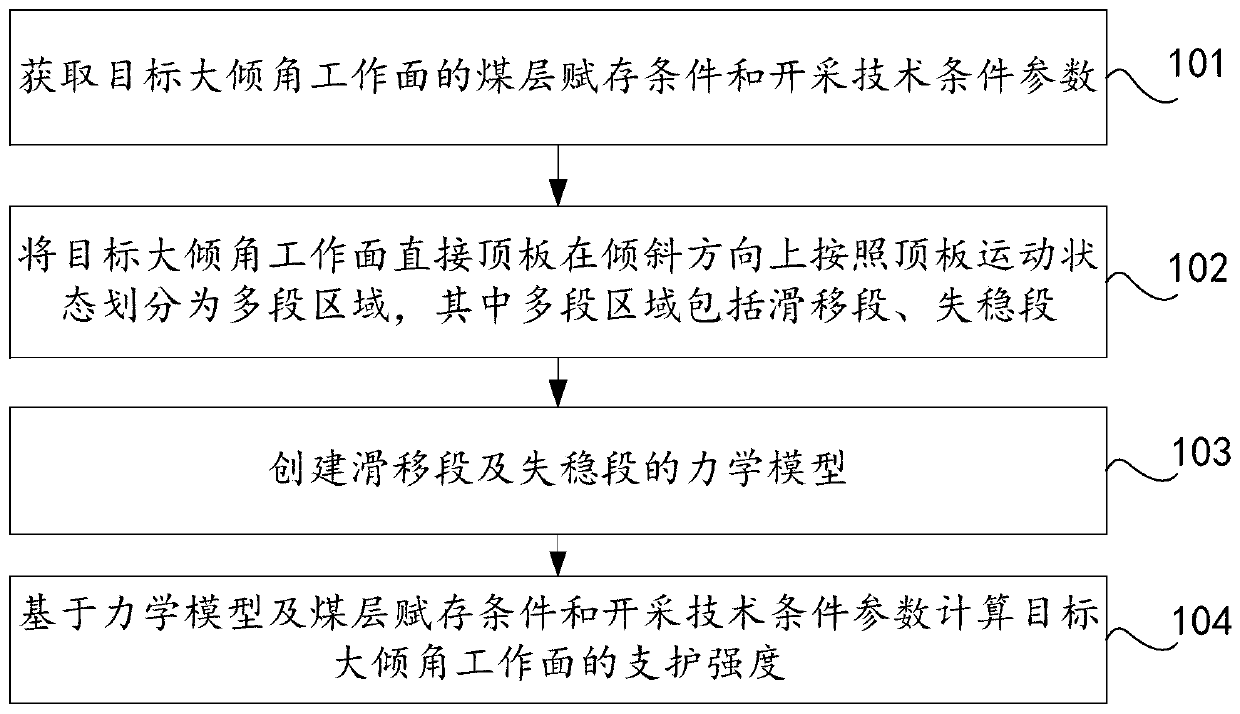

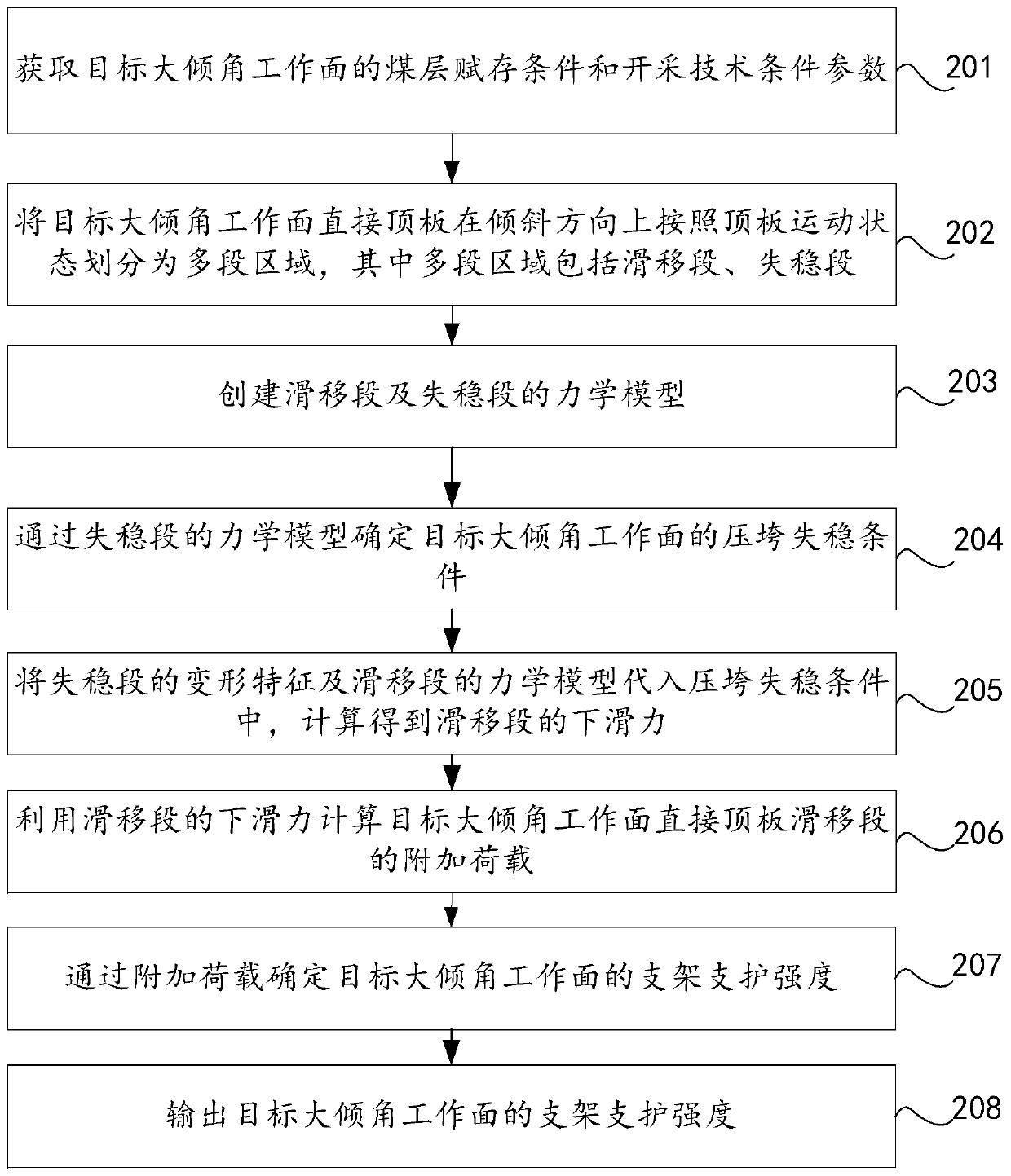

[0029] In view of the problem that the support strength of the fully mechanized mining face with a large inclination angle cannot be accurately determined when mining a coal seam with a large inclination angle, which may easily cause a collapse accident of the support of the working face, this embodiment provides a support strength of the fully mechanized mining face with a large inclination angle method of determination, such as figure 1 As shown, the method includes:

[0030] 101. Obtain the coal seam occurrence conditions and mining technical condition parameters of the target high-inclination working face.

[0031] Among them, the coal seam occurrence conditions and mining tec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com