Anti-glare protective film and preparation method thereof

An anti-glare and protective film technology, applied in the field of film materials, can solve problems such as traffic accidents, pedestrian visual interference, and illusions, and achieve the effect of solving glare problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

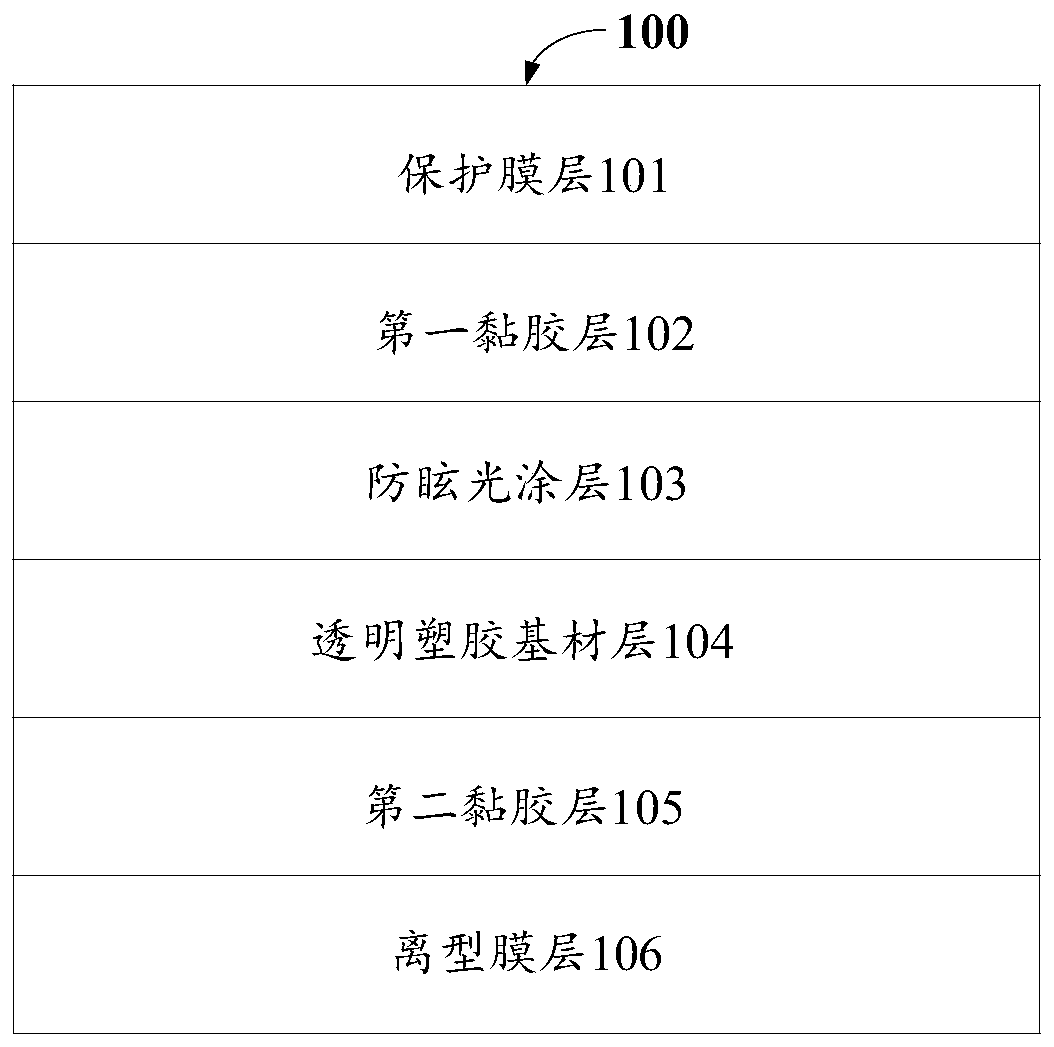

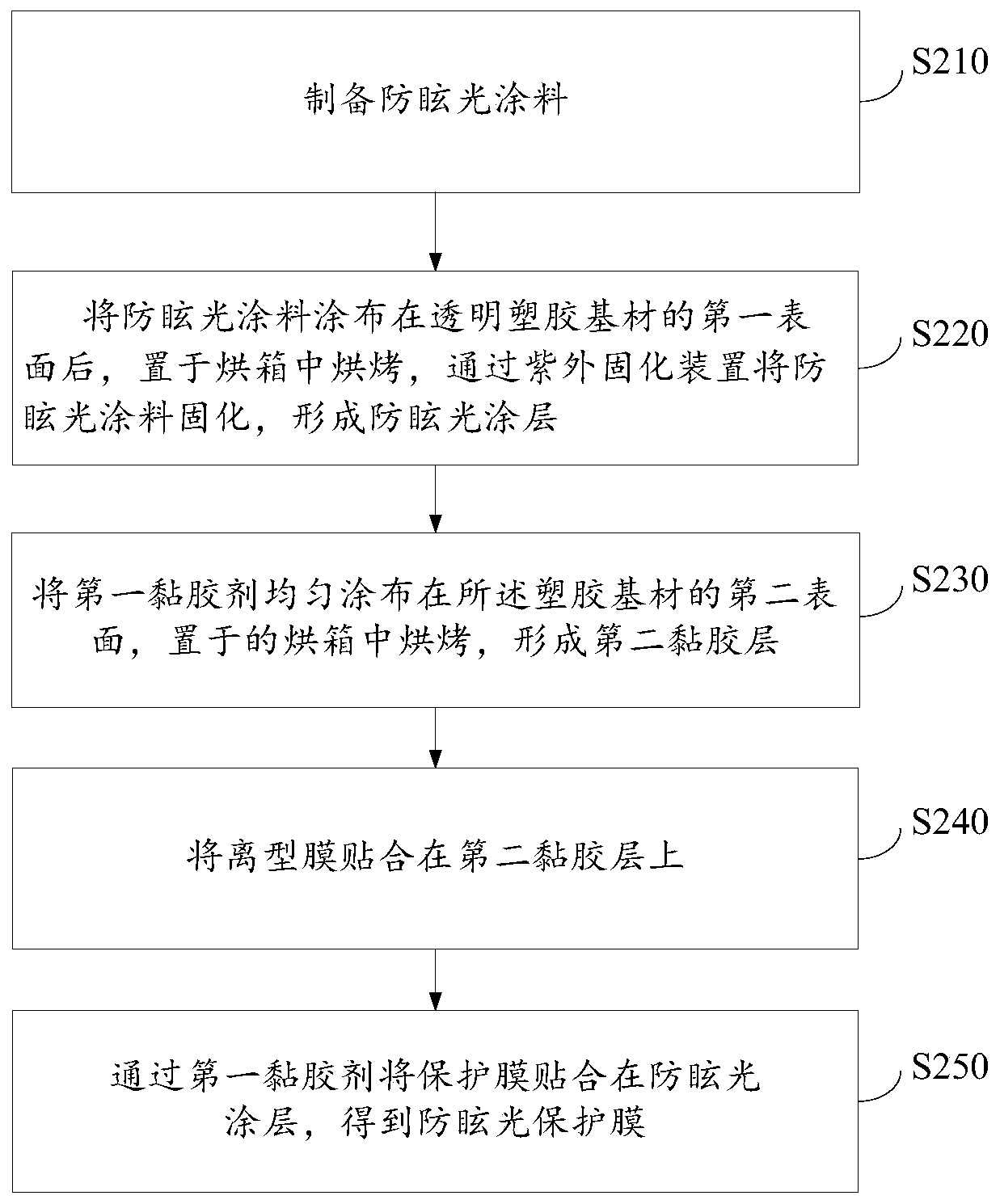

[0043] see figure 2 , the embodiment of the present invention also provides a preparation method of an anti-glare protective film, the method comprising the following steps:

[0044] S210. Preparation of waterborne polyurethane anti-glare coating.

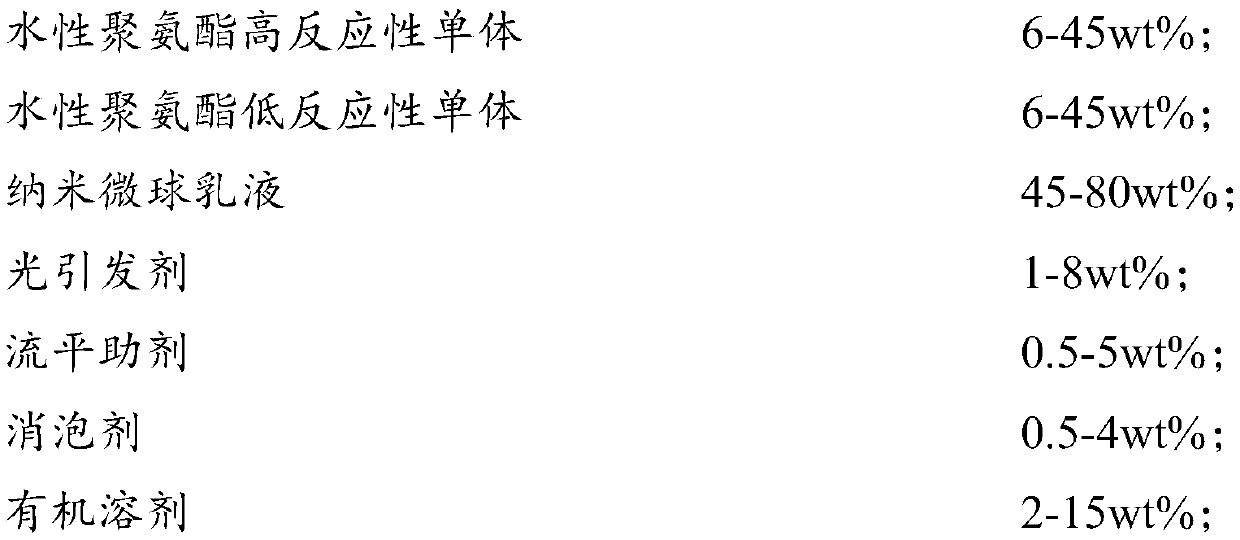

[0045] In this example, after mixing the water-based polyurethane high-reactivity monomer, water-based polyurethane low-reactivity monomer, photoinitiator and solvent evenly, then adding nano-microsphere emulsion, leveling aid and defoamer to stir and disperse evenly to obtain Waterborne polyurethane anti-glare coating.

[0046] In some embodiments, 6-45wt% of water-based polyurethane high-reactivity monomer and 6-45wt% of water-based polyurethane low-reactivity monomer are blended with 45-80wt% nanosphere emulsion, and then 0.5-4wt % defoamer, 0.5-5wt% leveling aid, 2-15wt% organic solvent and 1-8wt% photoinitiator, continuously disperse on a high-speed disperser for 20-40min, stand for 20-40min for defoaming, An anti-glare co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com