High-temperature fuel cell test system

A high-temperature fuel cell and test system technology, which is applied to the components of electrical measuring instruments, measuring electronics, and measuring devices, can solve the problem of high cost and achieve the effect of simple structure and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

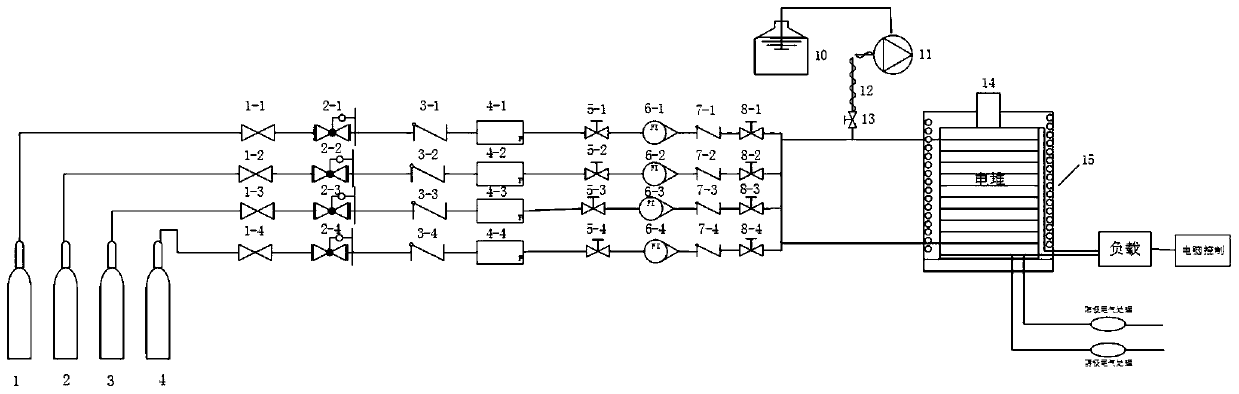

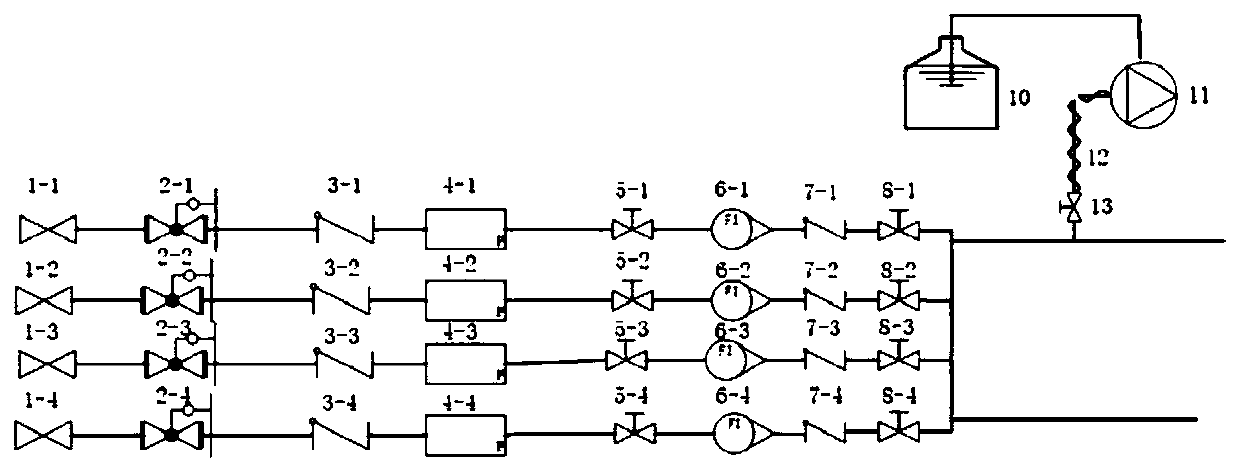

[0039] Test the performance of a solid oxide fuel cell stack with a power of 1kW;

[0040] 1. Preparation of fuel gas: the first gas cylinder 1 is hydrogen, the second gas cylinder 2 is nitrogen, and the third gas cylinder 3 is oxygen (or replace the third gas cylinder 3 with an air compressor, a fuel cell Cathode intake air);

[0041]2. The liquid storage tank 10 is distilled water, and the peristaltic pump 11 provides the water required for the test for the stack, and the heating cable 12 heats the water into water vapor;

[0042] 3. Put the solid oxide fuel cell to be tested in a high temperature furnace and heat it to a target temperature of 750°C;

[0043] 4. Open the control valves corresponding to gas cylinders 1, 2, and 3. At this time, the fourth gas cylinder 4 and the corresponding valve are not in use. Open the rotary valve d13 that controls the entry of water vapor, and adjust the valve to make the corresponding target gas The flows are, respectively, H 2 : 12.5...

Embodiment 2

[0047] Testing the performance of a molten carbonate fuel cell stack with a power of 1kW

[0048] 1. Preparation of fuel gas, the first gas cylinder 1 is hydrogen, the second gas cylinder 2 is nitrogen, and the third gas cylinder 3 is oxygen (or replace the gas cylinder 3 with an air compressor, and the fuel cell cathode intake air), the fourth gas cylinder 4 is carbon dioxide, and the liquid storage tank 10, the peristaltic pump 11 and the screw valve d13 are closed simultaneously;

[0049] 2. Place the solid oxide fuel cell to be tested in a high temperature furnace and heat it to a target temperature of 750°C;

[0050] 3. Open the control valves corresponding to gas cylinders 1, 2, 3, and 4, and adjust the valves so that the corresponding target gas flows are, H 2 : 10.5-13.5L / min; N 2 : 1.5-2.6L / min; Air: 29-31L / min; CO 2 : 10-12L / min;

[0051] 4. After the fuel gas is passed into the fuel cell, the open-circuit voltage test is performed first, and the discharge test i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com