Method for optical detection of battery pack

A technology for optical detection and battery packs, which is applied in the direction of optical testing for flaws/defects, material analysis through optical means, and measurement devices. It can solve the problems of low efficiency of manual detection of battery packs, avoid time-consuming and improve work efficiency. , the effect of improving the detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

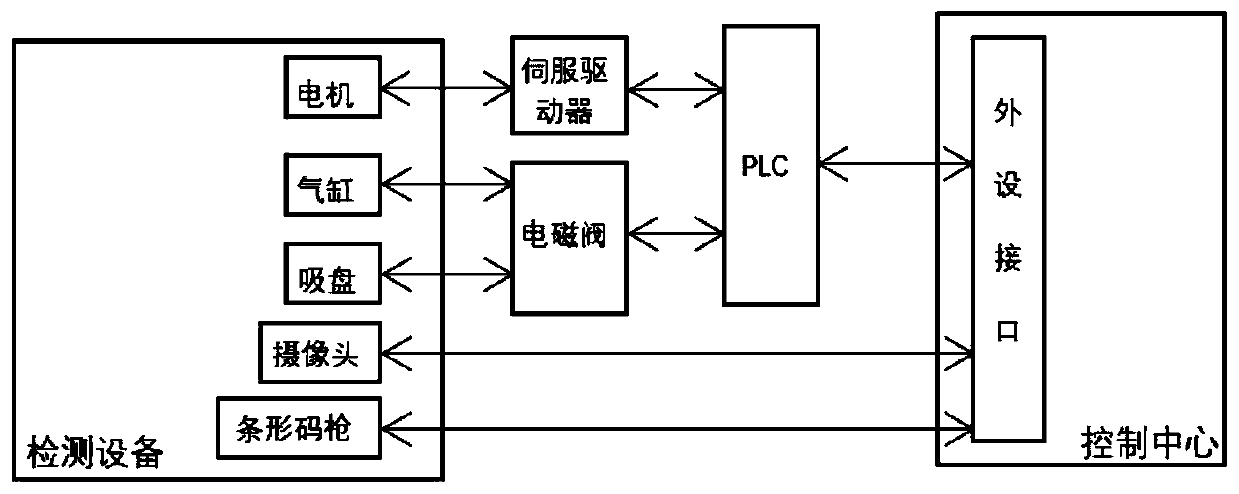

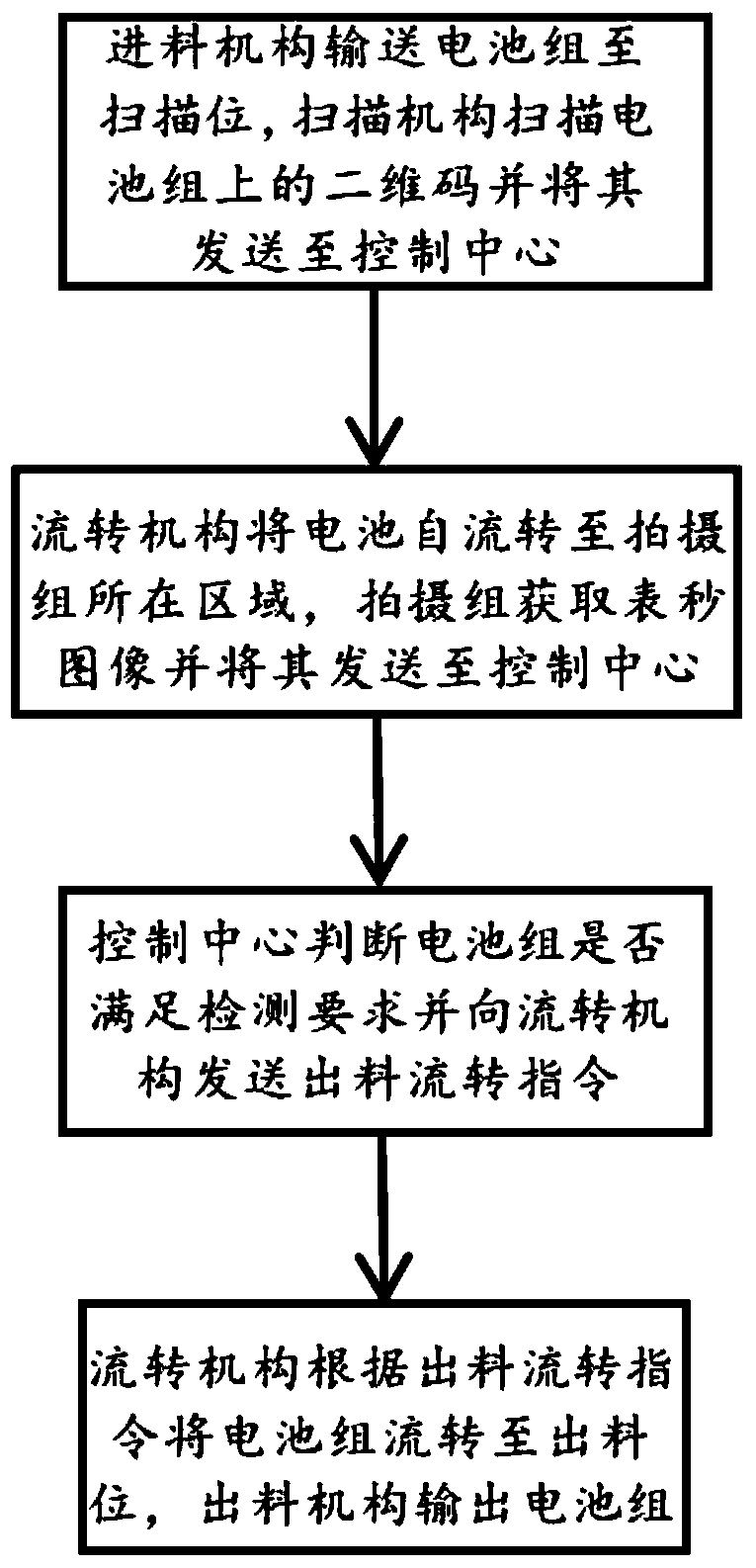

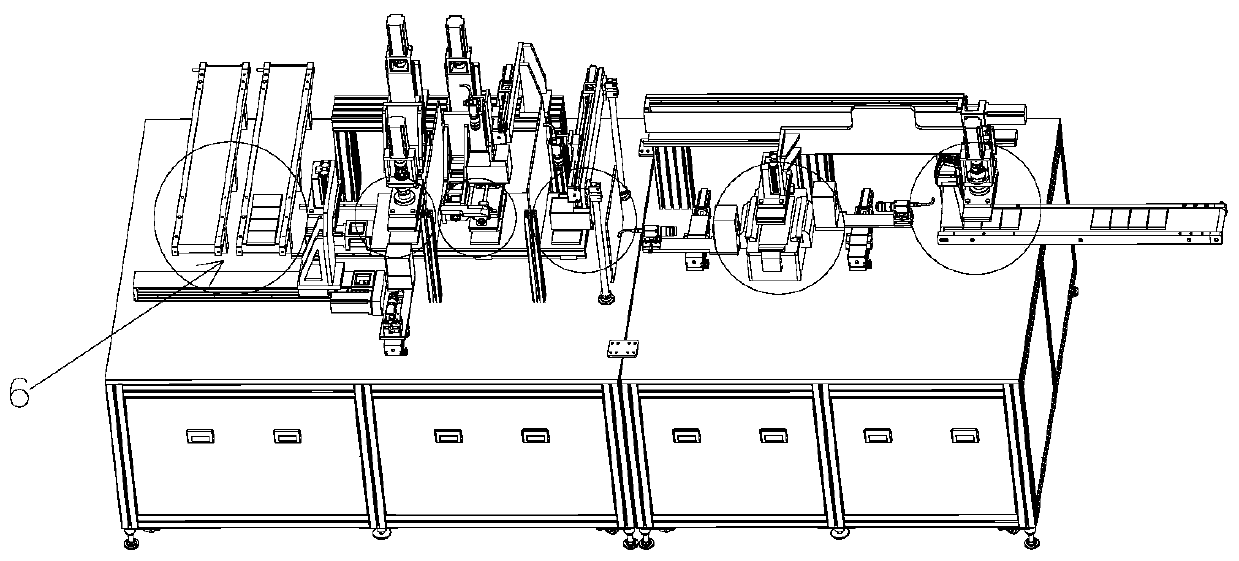

[0057] Such as Figure 3-9 Shown is a system diagram for implementing the optical detection method for battery packs, including detection equipment and a control center.

[0058] The detection equipment includes a circulation mechanism, a feeding mechanism, a scanning mechanism, a shooting group and a discharging mechanism.

[0059]The transfer mechanism includes a first transfer mechanism, a second transfer mechanism and a third transfer mechanism. The first transfer mechanism is used to sequentially transfer the battery pack from the scanning position 1 to the first transfer position 2 and the second transfer position 3. The second transfer mechanism It is used to transfer the battery pack from the second transfer position 3 to the third transfer position 4 and the fourth transfer position 5 in sequence, and the third transfer mechanism is used to transfer the battery pack from the fourth transfer position 5 to the discharge position 6 .

[0060] The scanning mechanism is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com