A mixed flow fan

A mixed-flow fan and collector technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as weakening the impeller's working ability, and achieve the effect of small product size, overcoming flow resistance, and large diameter ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

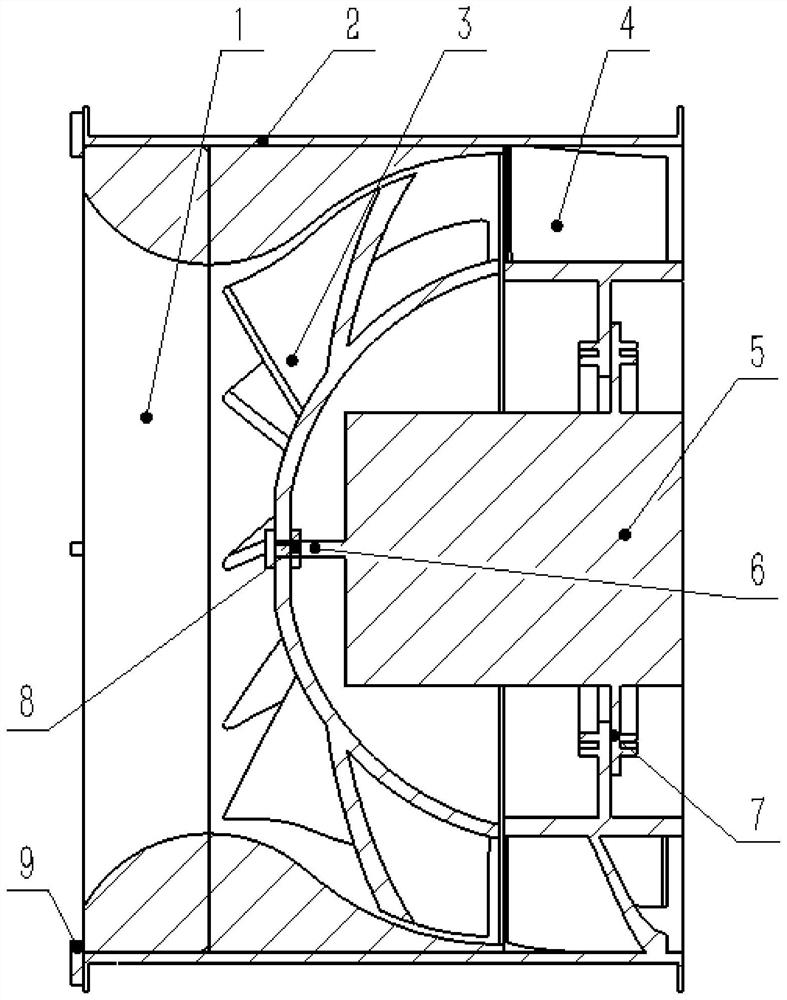

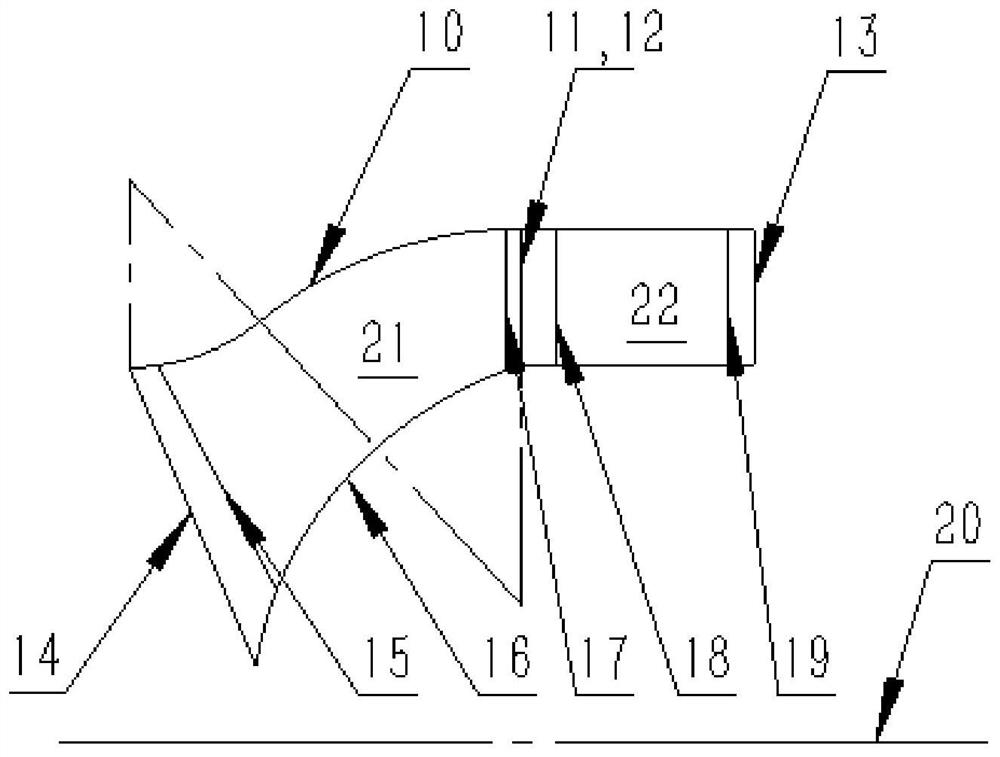

[0031] The present invention is further described below in conjunction with accompanying drawing:

[0032] see figure 1 and figure 2 , a mixed-flow fan, including a motor 5, a casing 2, an impeller 3, a guide vane 4 and a collector 1; the inside of one end of the casing 2 is coaxially fixed with a guide vane 4, and the motor 5 is arranged on the hub of the guide vane 4 The center; the output shaft of the motor 5 is fixedly connected to the center of the impeller 3; the other end of the casing 2 is provided with a current collector 1 on the same side as the impeller 3; the diameter of the hub of the guide vane 4 is the same as that of the impeller 3 ;

[0033] A number of blades are arranged at equal intervals on the impeller 3, and the blades are arranged along the hub line of the impeller 3; the edges of the blades relative to the hub are two sections of tangent circular arcs with opposite concavity and convexity, and the section close to the collector 1 is a concave secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com