Fuel injection valve and engine

A technology for fuel injection valves and valve sleeves, which is applied to fuel injection devices, engine components, machines/engines, etc. It can solve the problems of slow oil intake speed, long delay time for closing fuel injection valves, and affecting engine performance, etc., and achieves improvement. Response speed, effect of shortening off delay time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides an engine. The engine includes a fuel injection valve for injecting fuel into the combustion chamber of each cylinder of the engine.

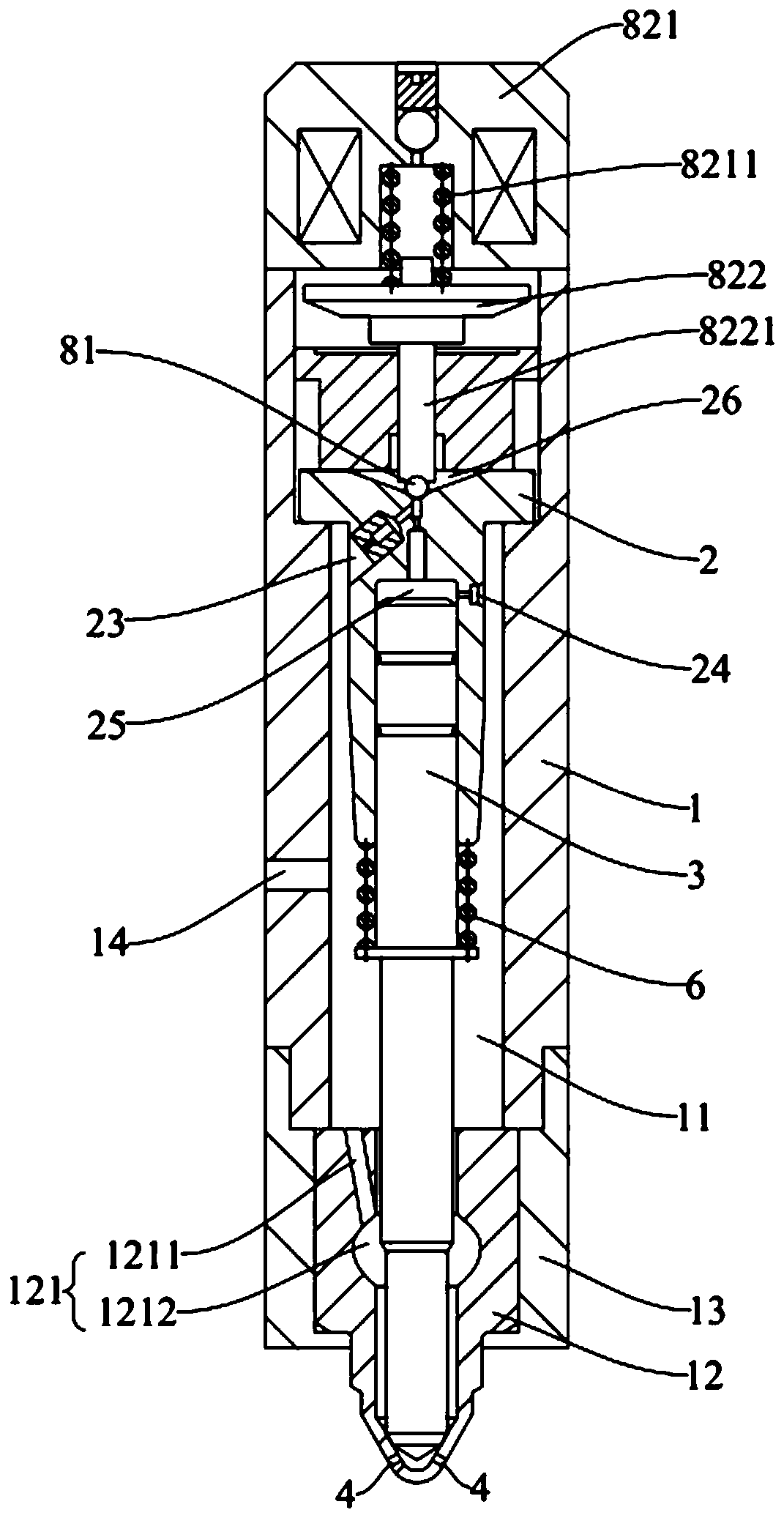

[0044] See Figure 1-Figure 6 The fuel injection valve provided in this embodiment includes an injection valve body 1, a valve sleeve 2 and a needle valve 3.

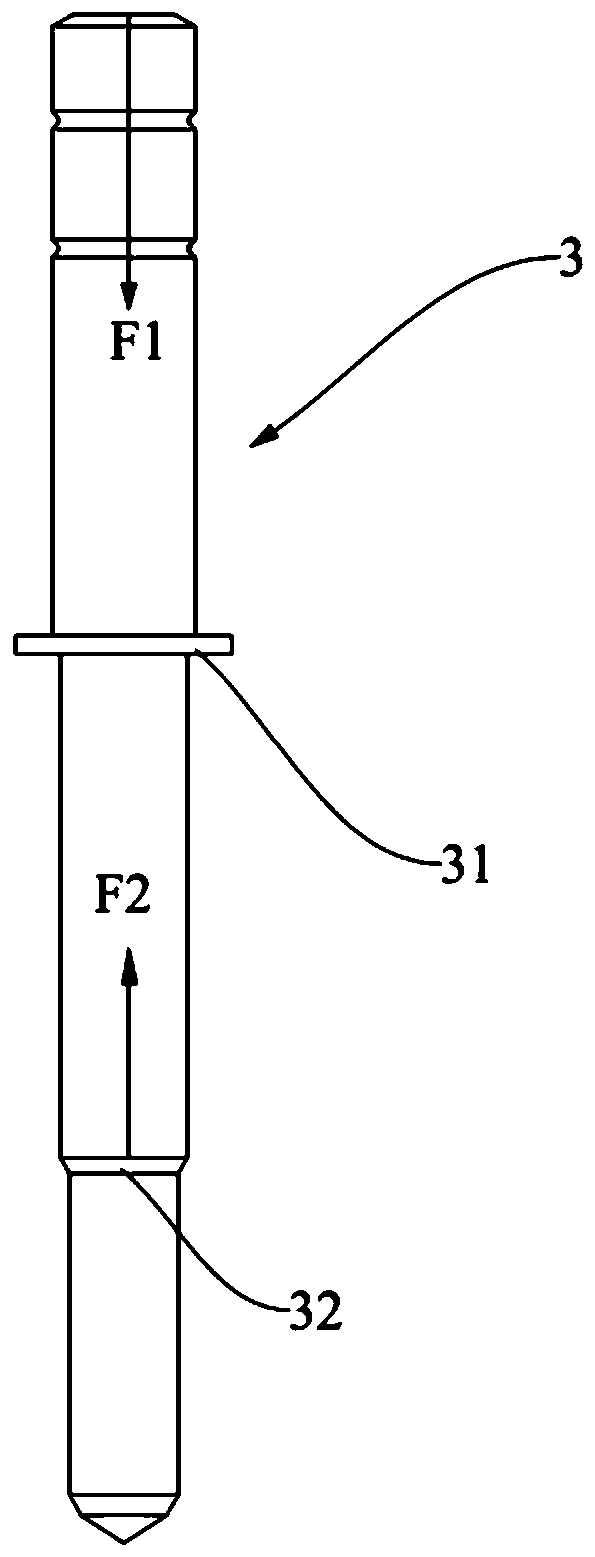

[0045] The injection valve body 1 has a high-pressure chamber 11 for containing fuel. An oil inlet 14 communicating with the high-pressure chamber 11 is opened on the side wall of the injection valve body 1. The fuel enters the high-pressure chamber 11 through the oil inlet 14. The two ends of the high-pressure chamber 11 have openings, one end of the high-pressure chamber 11 is blocked by the valve sleeve 2, and the other end is provided with a nozzle 12, and the end of the nozzle 12 is provided with a spray hole 4, which can be selectively opened or closed , Making the fuel injection valve open or closed. When the fuel injection valve is in an open state, i...

Embodiment 2

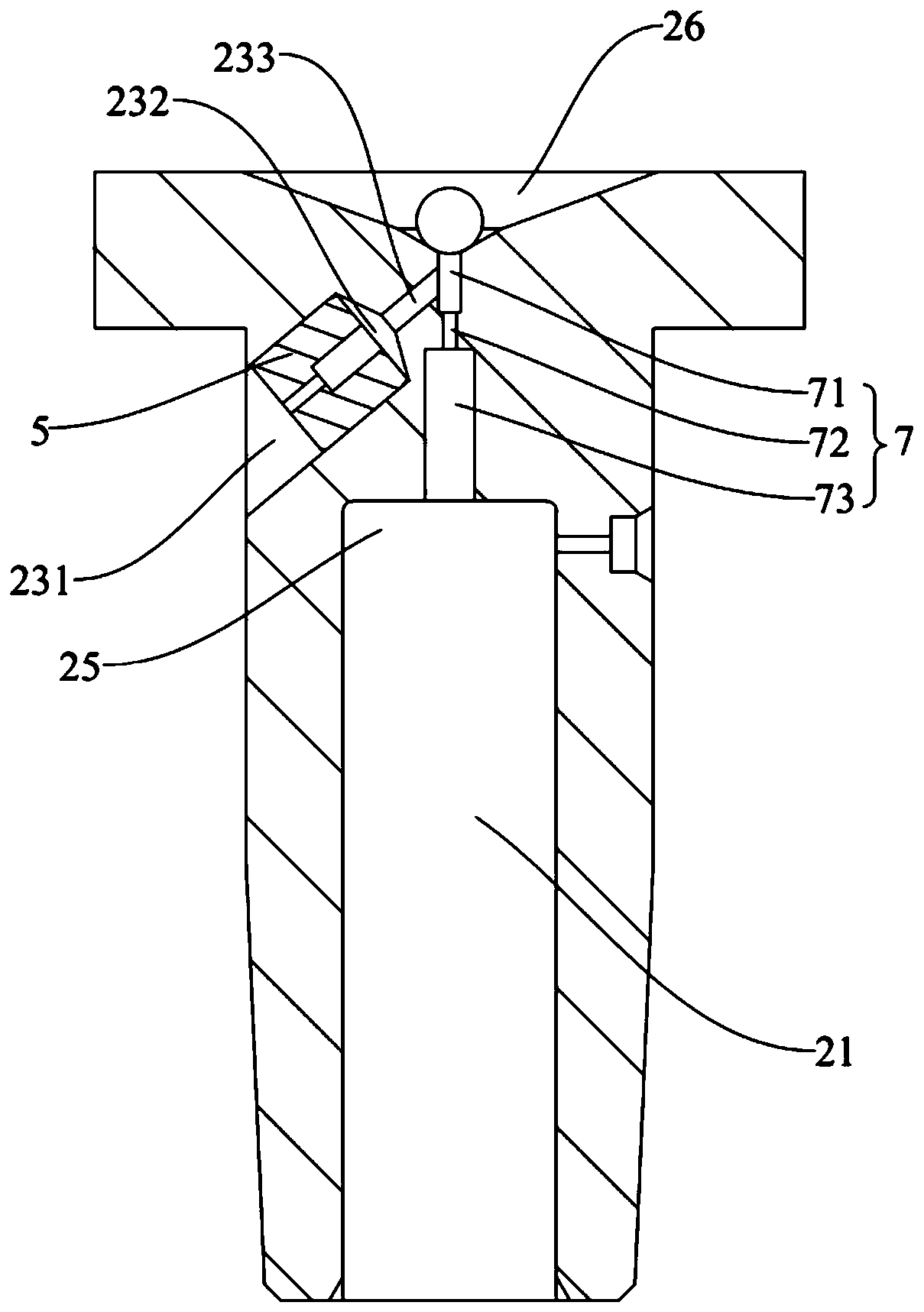

[0068] See Figure 7 The difference between this embodiment and the first embodiment is that the oblique oil outlet orifice 23 includes a second counterbore 234, a second tapered hole 235, a transition hole 236, and a second orifice 237 that are connected in sequence. The second counterbore 234 directly communicates with the high-pressure chamber 11, the large end opening of the second tapered hole 235 communicates with the second counterbore 234, the small end opening of the second tapered hole 235 is connected to the transition hole 236, and the second throttle The aperture of the hole 237 is smaller than the aperture of the transition hole 236. Specifically, in this embodiment, the second throttle hole 237 communicates with the upper counterbore 71 of the oil outlet hole 7.

[0069] In this embodiment, when the electromagnet 821 is de-energized, the sealing steel ball 81 is pressed against the sealing cone surface of the tapered low-pressure chamber 26 and the upper end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com