Electric control type engine braking device

An engine braking and electronically controlled technology, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of long intervention and exit time, unstable transient transition process of the engine, etc., and achieve the entry and exit time Shortening, reduction in oil demand and oil supply capacity of the oil pump, and reduction in fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

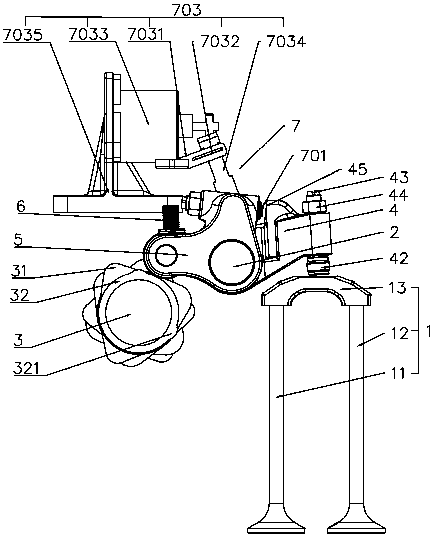

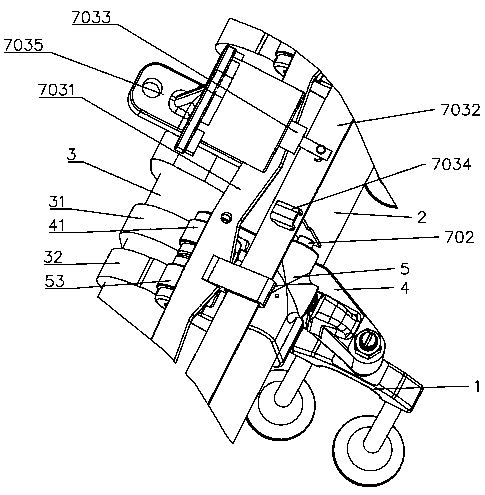

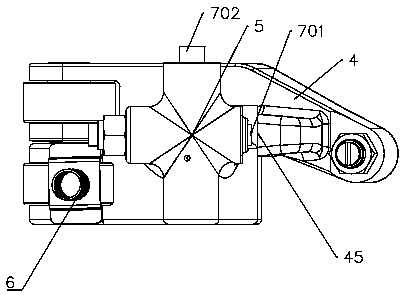

[0051] like Figure 1-4 As shown, an electronically controlled engine braking device includes an exhaust valve 1, a rocker shaft 2, a camshaft 3, an exhaust rocker 4, an auxiliary rocker 5, an elastic member 6, and an electronically controlled control mechanism 7.

[0052] The exhaust valve 1 includes a first exhaust valve 11, a second exhaust valve 12, and a valve bridge 13 horizontally arranged on the first exhaust valve 11 and the second exhaust valve 12, the first exhaust valve 11 and the second exhaust valve 12 The second exhaust valves 12 all adopt mushroom valves, which are used to control the flow of gas between the combustion chamber in the engine and the intake and exhaust manifolds.

[0053] The rocker shaft 2 is arranged parallel to the camshaft 3, and the camshaft 3 has an exhaust cam 31 and an auxiliary cam 32 arranged adjacently. The rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com