Electromagnetic control engine braking device

A technology of engine braking and electromagnetic control, which is applied in the direction of valve driving devices, engine components, machines/engines, etc., can solve the problems of long time for intervention and exit, unstable transient transition process of the engine, etc., and achieve lifting entry and exit speed, removal of reliability risks, and reduced entry and exit times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] Embodiments of the present invention will be further described below in conjunction with accompanying drawings:

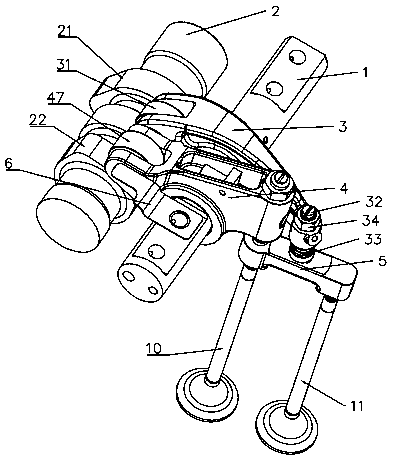

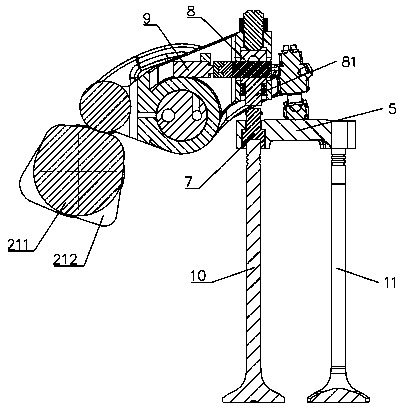

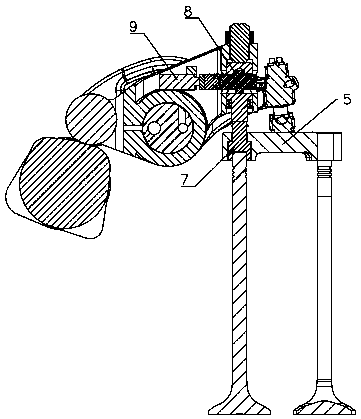

[0063] As shown in the figure, an electromagnetically controlled engine braking device includes a first exhaust valve 10, a second exhaust valve 11, a rocker shaft 1, a camshaft 2, an exhaust rocker 3, an auxiliary rocker 4, Valve bridge 5, elastic member 6, sliding pin 7, action mechanism 8, electromagnetic controller 9.

[0064] The first exhaust valve 10 and the second exhaust valve 11 adopt mushroom valves, which are used to control the flow of gas between the combustion chamber in the engine and the intake and exhaust manifolds.

[0065] The camshaft 2 is arranged parallel to the rocker arm shaft 1, and the camshaft 2 is provided with a first cam 21 and a second cam 22 arranged adjacently; the exhaust rocker arm 3 is adjacent to the auxiliary rocker arm 4 It is rotatably mounted on the rocker shaft 1 , the rear end of the exhaust rocker arm 3 correspon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com