Shield tunnel segmental lining structure suitable for building metro under narrow pavement

A shield tunnel segment and segment technology, which is applied to tunnel lining, tunnel, wellbore lining, etc., can solve the problems of bulky and bulky special-shaped connecting segments, difficulty in mold manufacturing and reinforcement, and unfavorable mass production. The effect of uneven settlement, improving longitudinal rigidity and making full use of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

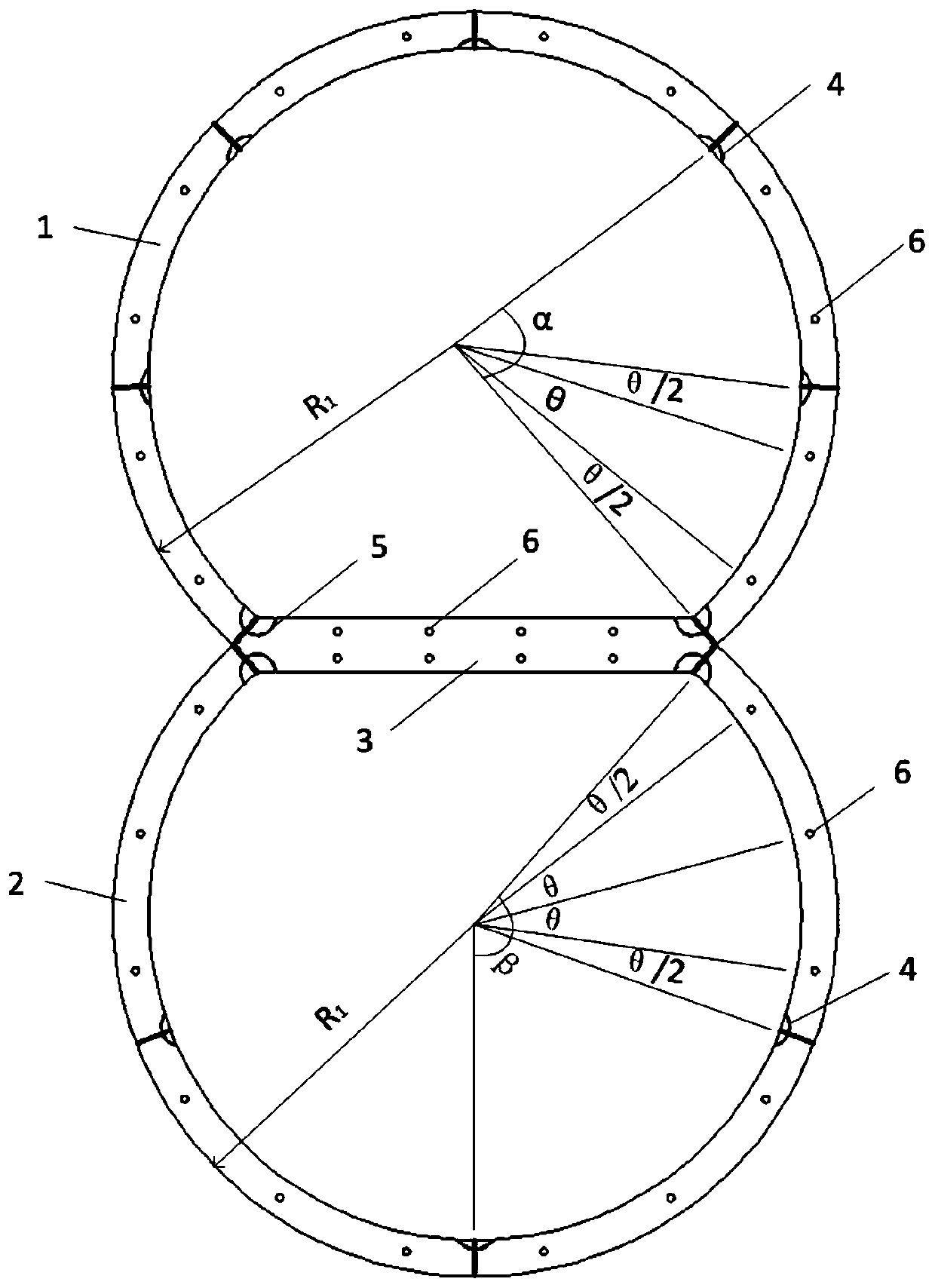

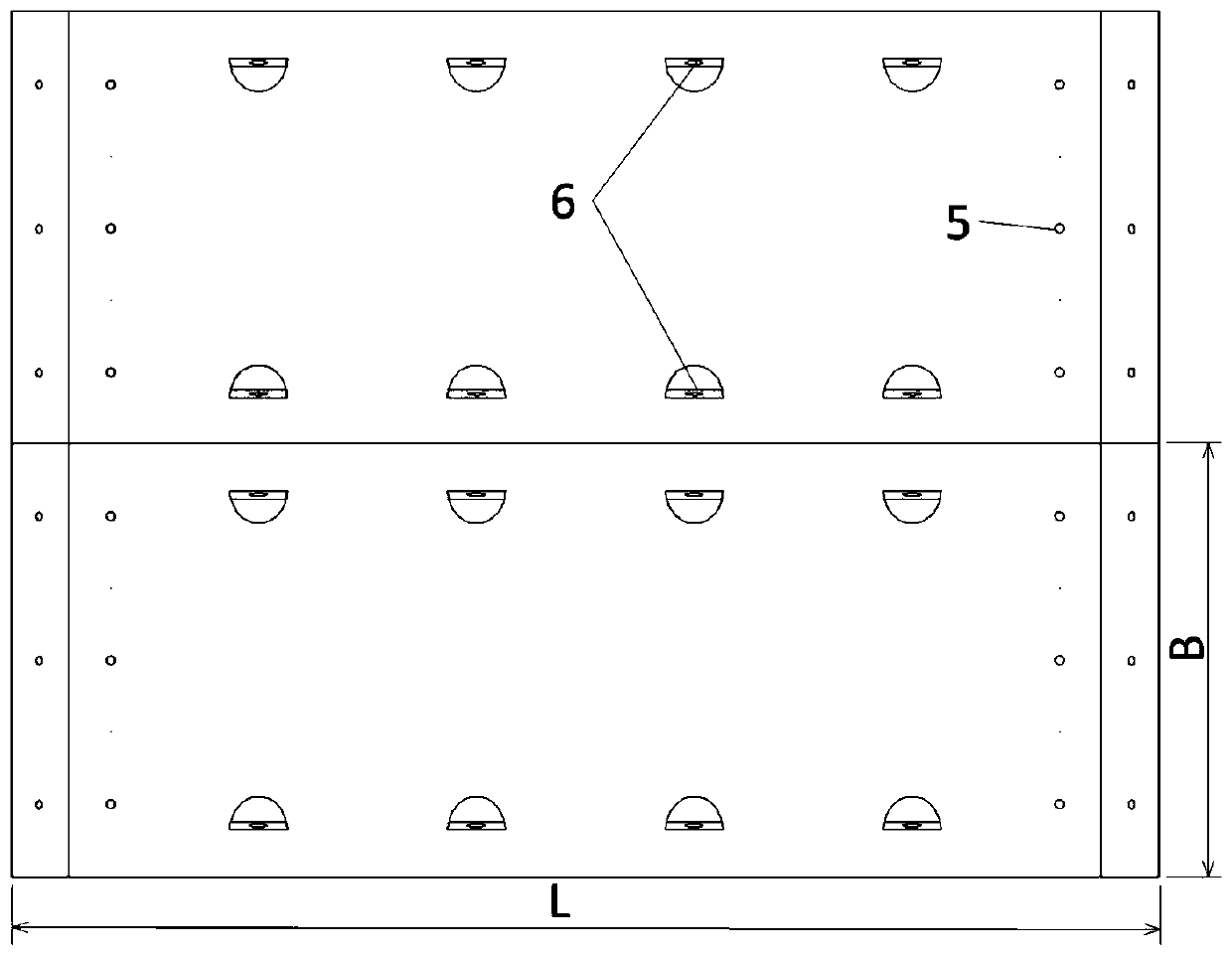

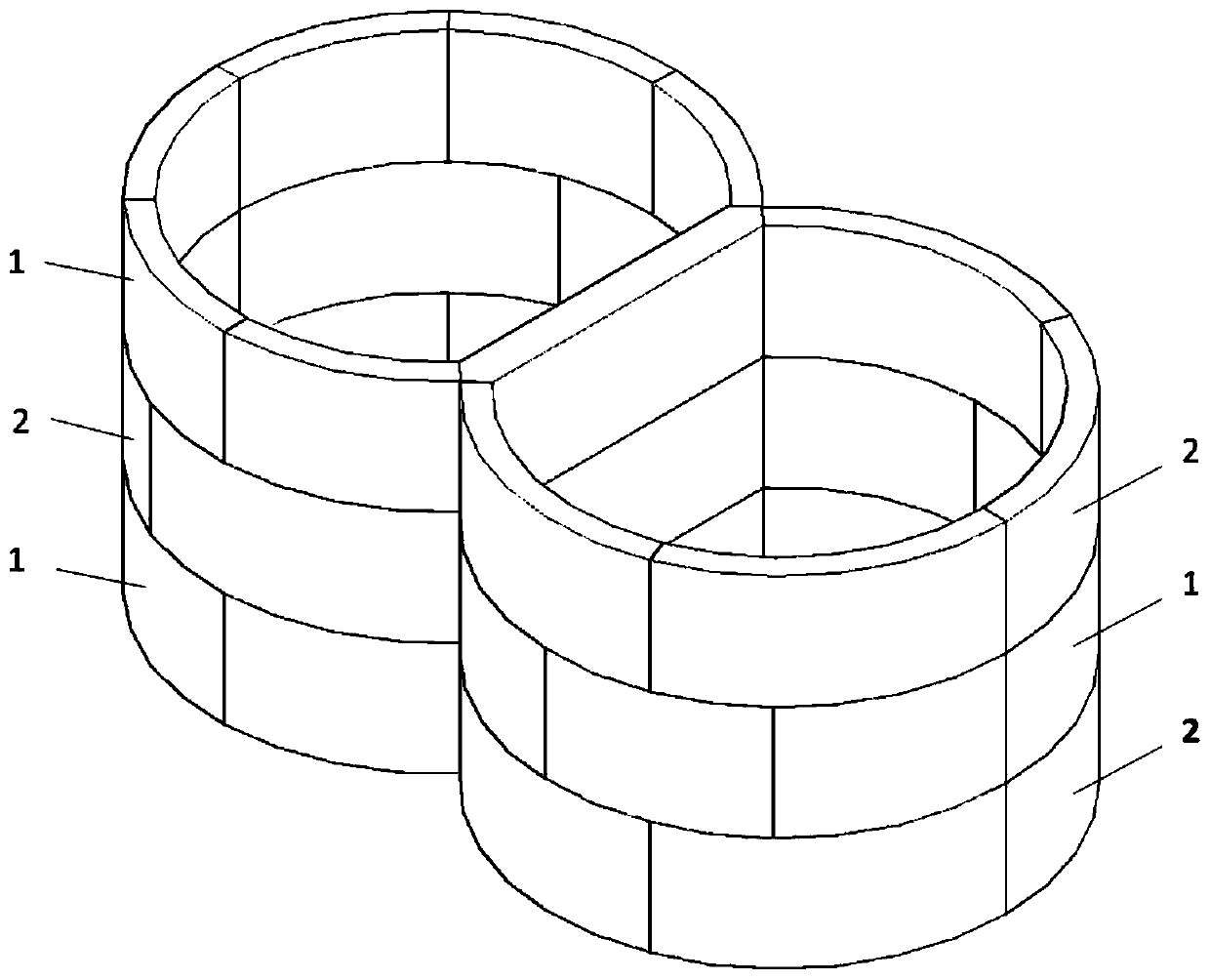

[0028] Please refer to figure 1 , this embodiment provides a shield tunnel segment lining structure suitable for building subways under narrow roads, which includes: a-type segment ring, b-type segment ring and middle plate 3, a-type segment ring includes a plurality of The A-type segment 1 assembled in the circumferential direction, the b-type segment ring includes a plurality of B-type segments 2 assembled in the circumferential direction, the a-type segment ring and the b-type segment ring respectively form a superior arc on both sides of the middle plate 3 Ring-shaped structure, the two ends of the middle plate 3 are matched with the A-type segment 1 and the B-type segment 2 respectively and have a flat connection surface, and the A-type segment 1, the B-type segment 2 and the middle plate 3 are connected to form "8"-shaped structural ring, multi-segment structural rings are connected to form an integrated shield tunnel segment lining, a-type segment rings and b-type segme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com