A washing machine with partial pre-washing function

A washing machine and functional technology, applied in the field of washing machines with partial pre-washing function, can solve the problems of oil stain shedding, excessive washing machine space, large loss, etc., and achieve the effect of avoiding obstruction and influence, compact and reasonable structure, and fast and thorough removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

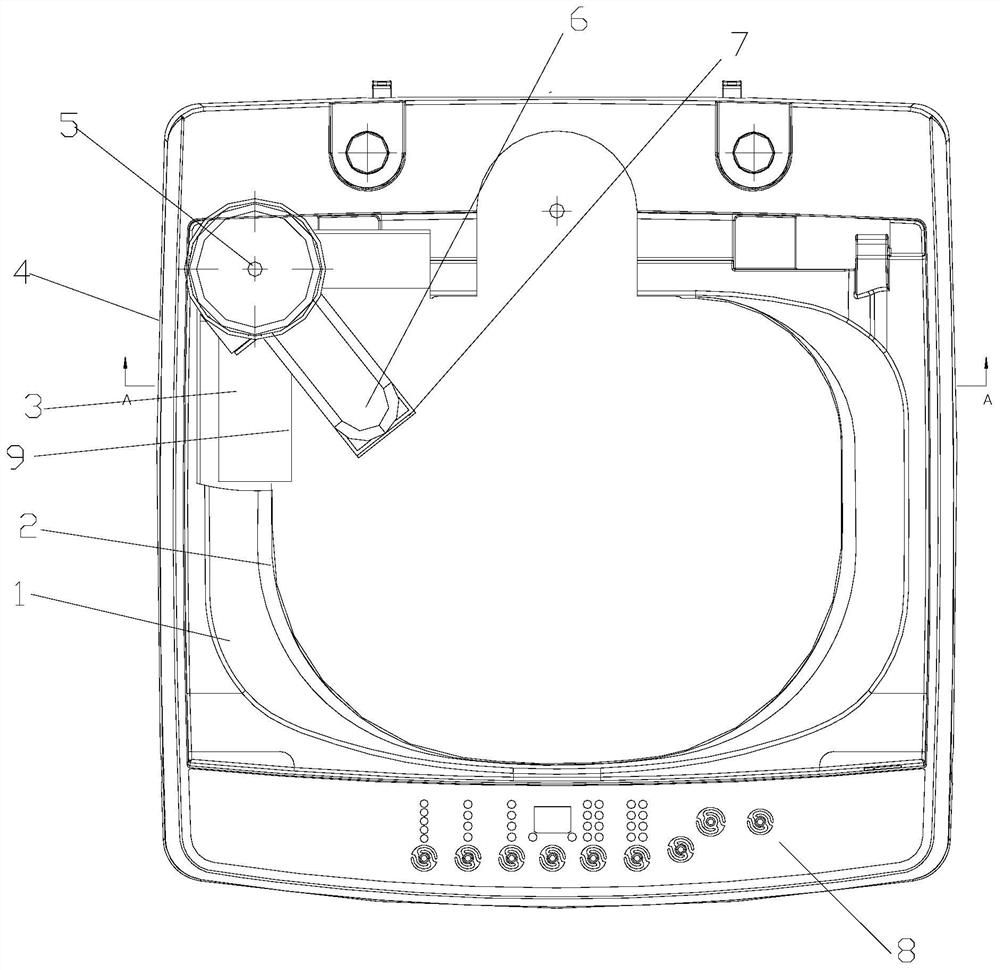

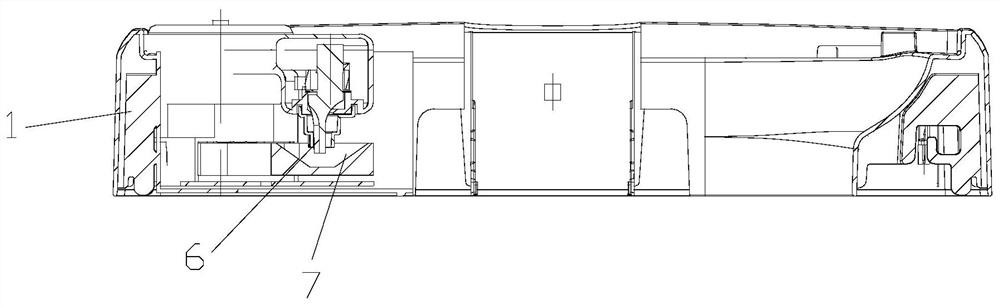

[0048] Such as Figure 1-6 As shown, the object of the present invention is to provide a washing machine with a partial prewash function. The washing machine includes an ultrasonic cleaning device; the ultrasonic cleaning device includes an interconnected ultrasonic generating device 6 and a cleaning tank 7 located below the ultrasonic generating device 6 , and the two are connected to each other through a rotatable connection device 5 . The ultrasonic cleaning device is rotatably connected with the control panel base 1 of the washing machine through the rotatable connection device 5 . The control panel base 1 has an accommodating space 3 for accommodating the ultrasonic cleaning device. Such as figure 1 and image 3 As shown, the ultrasonic cleaning device is arranged in the accommodation space 3 so that it can be screwed in / out.

[0049] The ultrasonic washing device independently pre-treats or washes the clothes by means of ultrasonic washing; the ultrasonic washing dev...

Embodiment 2

[0059] This embodiment is a supplement to embodiment 1, such as Figure 1 to Figure 5 As shown, this embodiment discloses a washing machine with a partial pre-washing function using the control panel base of the washing machine described in Embodiment 1. The washing machine includes an ultrasonic cleaning device as in Embodiment 1; the control panel base 1 has an accommodating space 3 for accommodating the ultrasonic cleaning device, and the ultrasonic cleaning device can be screwed in / out to be arranged in the accommodating space 3 Inside.

[0060] The washing bucket and the ultrasonic washing device of the washing machine in this embodiment can work independently respectively, the washing bucket is used to clean the whole and relatively large amount of clothing, and the ultrasonic washing device is mainly used to clean some parts of the clothing that are not easy to be cleaned. Such as collars, cuffs, clothes edges, etc., pretreatment or separate ultrasonic washing can also...

Embodiment 3

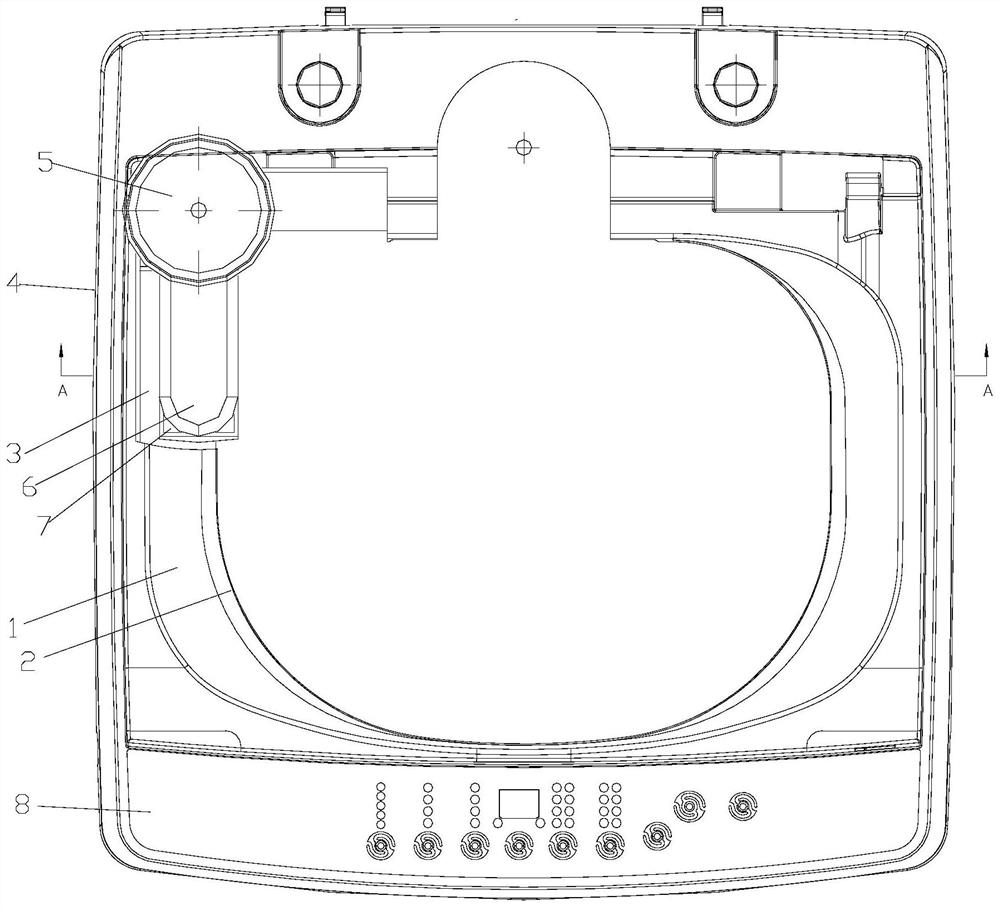

[0073] The difference between this embodiment and embodiment 2 is that, as figure 1 and 3 and Figure 6 As shown, the ultrasonic generating device in this embodiment is connected to the cleaning tank through a movable connection device, so that there are at least two different relative positions between the ultrasonic generating device 6 and the cleaning tank 7 . Such as Figure 6 As shown, the ultrasonic generating device 6 and the cleaning tank 7 in this embodiment are connected through a rotatable device 5 . The ultrasonic generating device has a projection directly above the cleaning tank such as figure 1 The first working position shown, and the ultrasonic generating device rotates around the rotatable device to form an included angle with the cleaning tank, such as Figure 6 Second working position shown.

[0074] Such setting enables the ultrasonic generating device to have more new options when pre-washing the clothes. When there are large pieces of clothing, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com