A kind of waste purple miscellaneous copper refining agent and its preparation method and application

The technology of refining agent and purple miscellaneous copper is applied in the field of waste miscellaneous copper refining agent and its preparation. The effect of sufficient deoxygenation reaction and shortened reaction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Place the electrolytic copper with a purity of 99.99%-99.999% in a vacuum melting furnace. After the electrolytic copper is melted, the temperature of the melt is controlled at 1150-1200°C, and the vacuum is evacuated to 10 -2 Pa~10 -3Pa. Stop vacuuming, and pass into a high-purity inert gas with a purity of 99.999%, control the pressure in the furnace to be 1.0 atmospheric pressure, and use the following parts by weight of 25-30% parts of Cu-Mg alloy of Mg, 25-30% of parts of B Cu-B alloy, 50-65% Ce Cu-Ce alloy, 35-50% Y Cu-Y alloy, 35-50% Pr Cu-Pr alloy and 35-50% La Cu- La alloy and other intermediate alloys are put into the copper melt, kept at a temperature range of 1150-1200°C for 20 minutes, poured into a water-cooled iron mold to obtain a refining agent for copper, and the prepared refining agent is 3.8-5.3 parts by weight. B, 4.0-4.8 parts of Mg, 8.5-11 parts of Ce, 6.5-7.5 parts of Pr, 5 parts of Y, 5 parts of La. Take 100kg of waste red miscellaneous coppe...

Embodiment 2

[0044] Place the electrolytic copper with a purity of 99.99%-99.999% in a vacuum melting furnace. After the electrolytic copper is melted, the temperature of the melt is controlled at 1150-1200°C, and the vacuum is evacuated to 10 -2 Pa~10 -3 Pa. Stop vacuuming, and pass into a high-purity inert gas with a purity of 99.999%, control the pressure in the furnace to be 1.0 atmospheric pressure, and use the following parts by weight of 25-30% parts of Cu-Mg alloy of Mg, 25-30% of parts of B Cu-B alloy, 50-65% Ce Cu-Ce alloy, 35-50% Y Cu-Y alloy, 35-50% Pr Cu-Pr alloy and 35-50% La Cu- La alloy and other intermediate alloys are put into the copper melt, kept at a temperature range of 1150-1200°C for 20 minutes, poured into a water-cooled iron mold to obtain a refining agent for copper, and the prepared refining agent is 3.8-5.3 parts by weight. B, 4.0-4.8 parts of Mg, 8.5-11 parts of Ce, 6.5-7.5 parts of Pr, 3 parts of Y, 3 parts of La. Take 100kg of waste red miscellaneous copp...

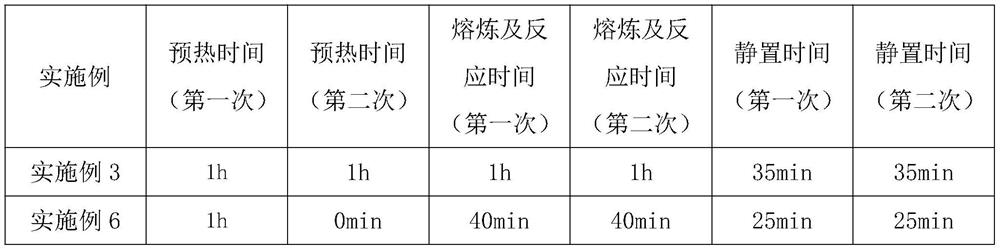

Embodiment 3

[0046] Place the electrolytic copper with a purity of 99.99%-99.999% in a vacuum melting furnace. After the electrolytic copper is melted, the temperature of the melt is controlled at 1150-1200°C, and the vacuum is evacuated to 10 -2 Pa~10 -3 Pa. Stop vacuuming, and pass into a high-purity inert gas with a purity of 99.999%, control the pressure in the furnace to be 1.0 atmospheric pressure, and use the following parts by weight of 25-30% parts of Cu-Mg alloy of Mg, 25-30% of parts of B Cu-B alloy, 50-65% Ce Cu-Ce alloy, 35-50% Y Cu-Y alloy, 35-50% Pr Cu-Pr alloy and 35-50% La Cu- La alloy and other intermediate alloys are put into the copper melt, kept at a temperature range of 1150-1200°C for 20 minutes, poured into a water-cooled iron mold to obtain a refining agent for copper, and the prepared refining agent is 3.8-5.3 parts by weight. B, 4.0-4.8 parts of Mg, 8.5-11 parts of Ce, 6.5-7.5 parts of Pr, 3.2 parts of Y, 3.2 parts of La. Take 100kg of waste red miscellaneous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com