A kind of halogen-free polyphenylene ether resin composition and prepreg and laminate made by using it

A technology of polyphenylene ether resin and resin composition, applied in the direction of synthetic resin layered products, chemical instruments and methods, layered products, etc., can solve the problem of affecting the compatibility of polyphenylene ether resin and crosslinking agent Heat and humidity resistance, affecting the heat resistance of the cured product, etc., to achieve the effect of avoiding low flame retardant efficiency, avoiding phase separation problems, and low dielectric loss value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0066] A kind of halogen-free polyphenylene ether resin composition, its formula is shown in following table 1:

[0067] Table 1

[0068]

[0069] The specific details of the above components are as follows in Table 2:

[0070] Table 2

[0071]

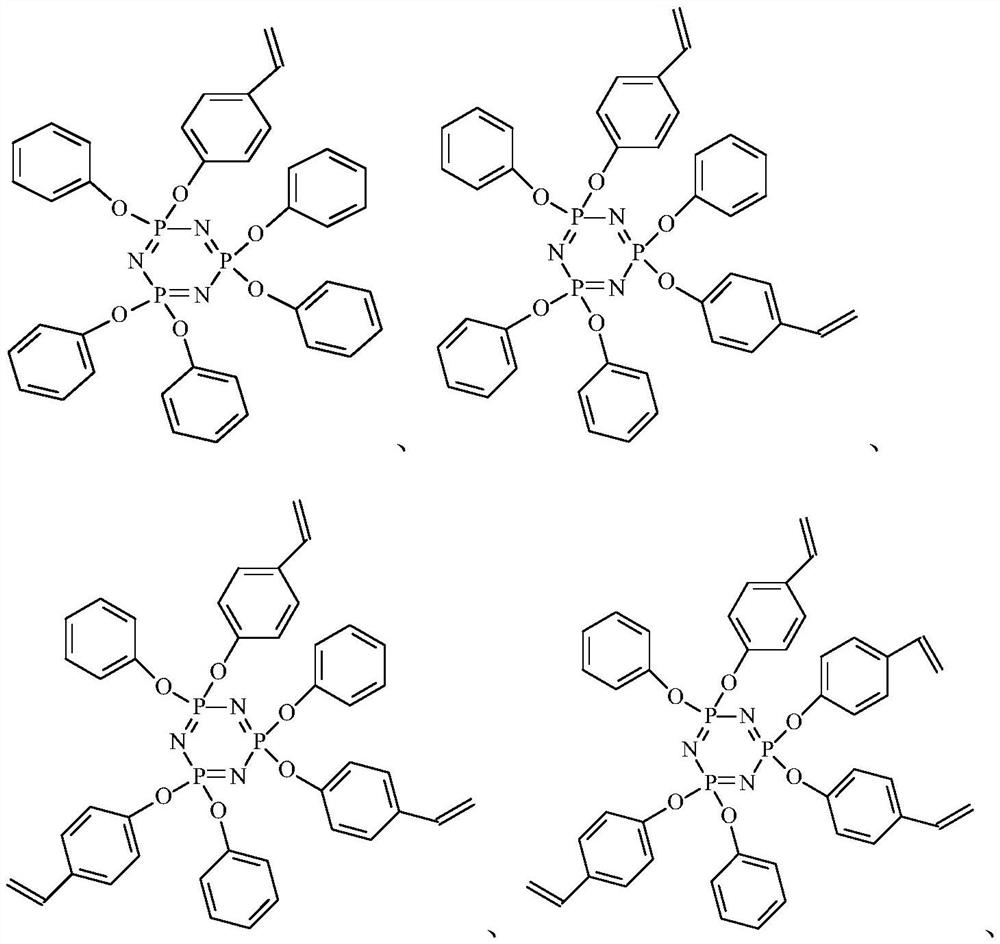

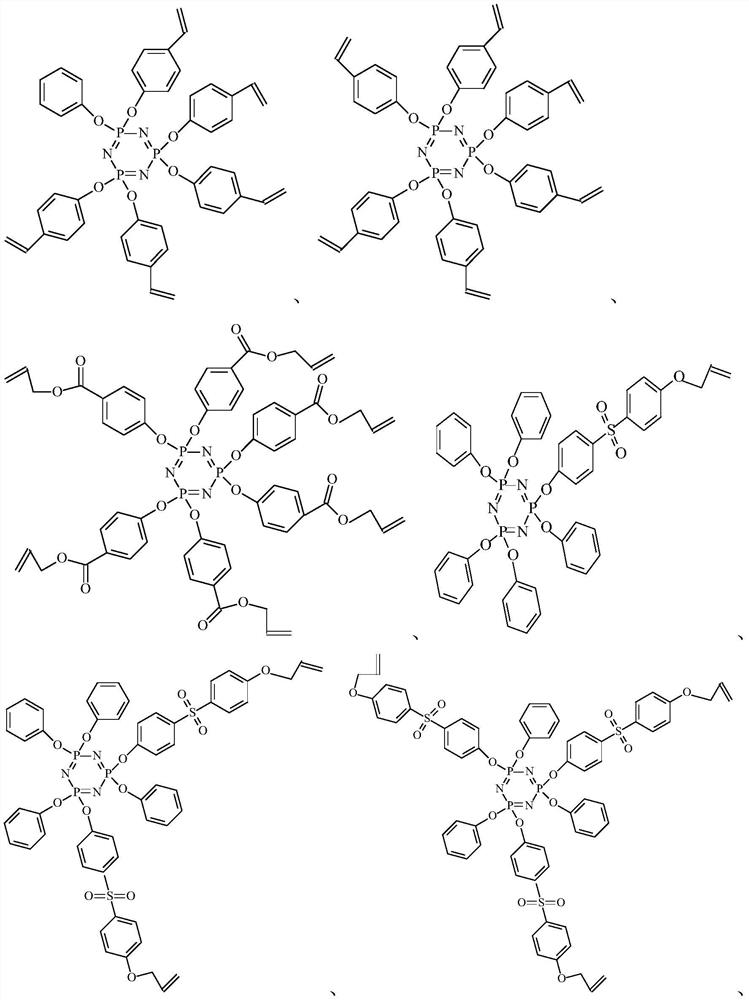

[0072] The synthesis method of the above-mentioned phosphorus-containing compound A: using hexachlorocyclotriphosphazene, 3-allylphenol and phenol as the main raw materials, a class of new allyl-containing Cyclic triphosphazene compound with base structure.

[0073] The synthetic method of above-mentioned phosphorus-containing compound B:

[0074]

[0075] The above resin composition is obtained by a conventional preparation method, and the polyphenylene ether, triallyl isocyanate, phosphorus-containing compound, initiator, and an appropriate amount of inorganic filler and solvent are added to the rubber mixing tank, and the solid content is 55-70%. , stir evenly, and ripen for 4 to 8 hours to make a resin composition glu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com