Carbon fiber implanted high-hardness surface microstructure and preparation method and device thereof

A microstructure and carbon fiber technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of high hardness surface wear and short service life of gear pairs, reduce friction, maintain sharpness, and protect knives Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

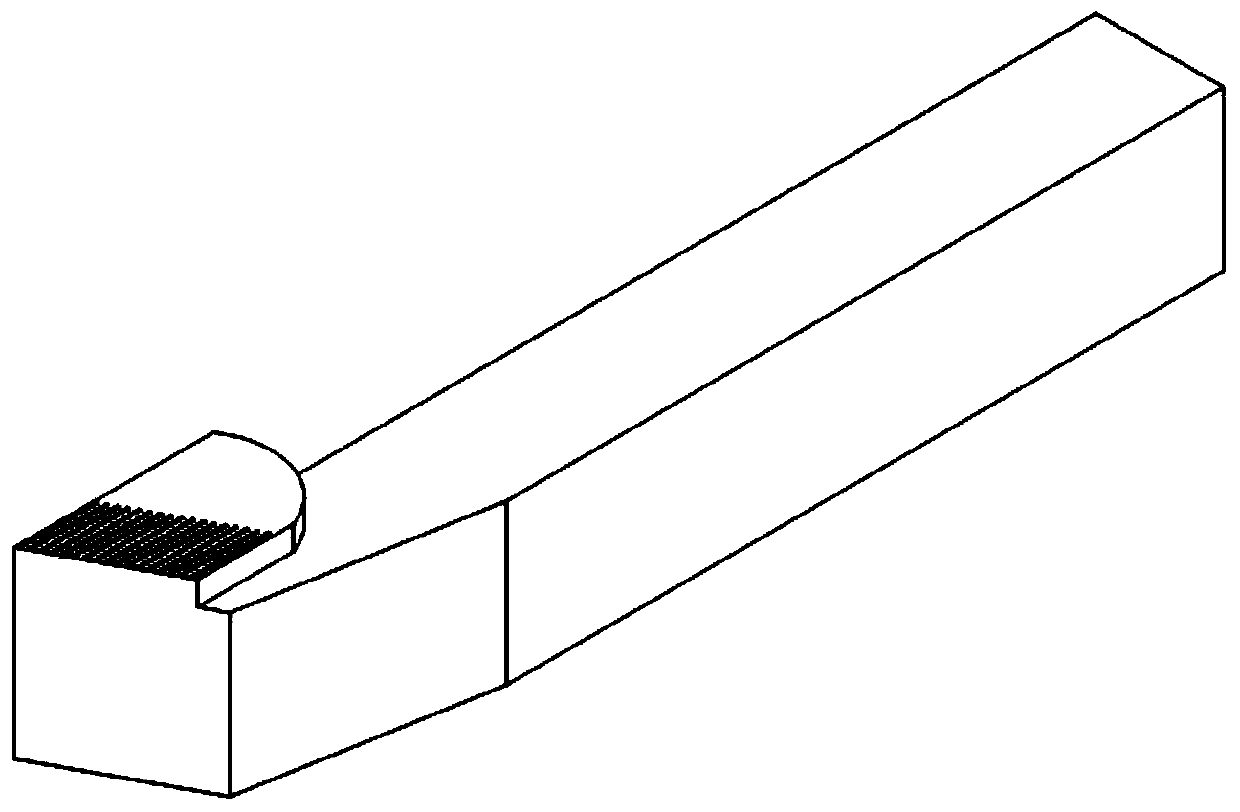

[0035] Such as Figure 6-1 As shown, the ant's mandibles can lift objects several times heavier than the body, and have good drag reduction, lubrication and anti-adhesion properties, and the pits and hairs on the surface play a certain role. A schematic diagram of the two mandibles of an ant and the pits and hairs on the mandibles is shown in Figure 6-2 , Figure 6-3 for Figure 6-2 Enlarged view of part A. The present invention is a high-hardness surface microstructure implanted with carbon fiber, which is a high-hardness surface microstructure imitating the surface of the ant's mouthparts (high-hardness mandible surface + bristles), and a bionic microstructure is set on the high-hardness surface, and the high-hardness surface can be Be blade, titanium alloy surface, granite surface etc.; The high hardness surface of present embodiment is the rake face of turning tool, as figure 2 As shown, that is, this embodiment is the microstructure of the rake face of the turning t...

Embodiment 2

[0037] The rake face is provided with a turning tool with a microstructure implanted with carbon fibers. The rake face of the turning tool is provided with the microstructure implanted with carbon fibers in Example 1, and the material used is high-speed steel (W6Mo5Cr4V2).

Embodiment 3

[0039] In embodiment 2, the preparation method of the microstructure of the rake face of the turning tool implanted with carbon fibers is as follows:

[0040] Step 1. Use natural diamond to make a single-point diamond embossing knife for embossing the center rounding table pit, wherein the single-point diamond embossing knife is in the shape of a rounding table, and the busbar of the single-point diamond embossing knife and the clamp of the central axis Angle θ 2 = 45°, the minimum diameter d of a single-point diamond imprinting knife 2 =0.04mm; the total height h of the single-point diamond embossing knife 2 = 0.15 mm.

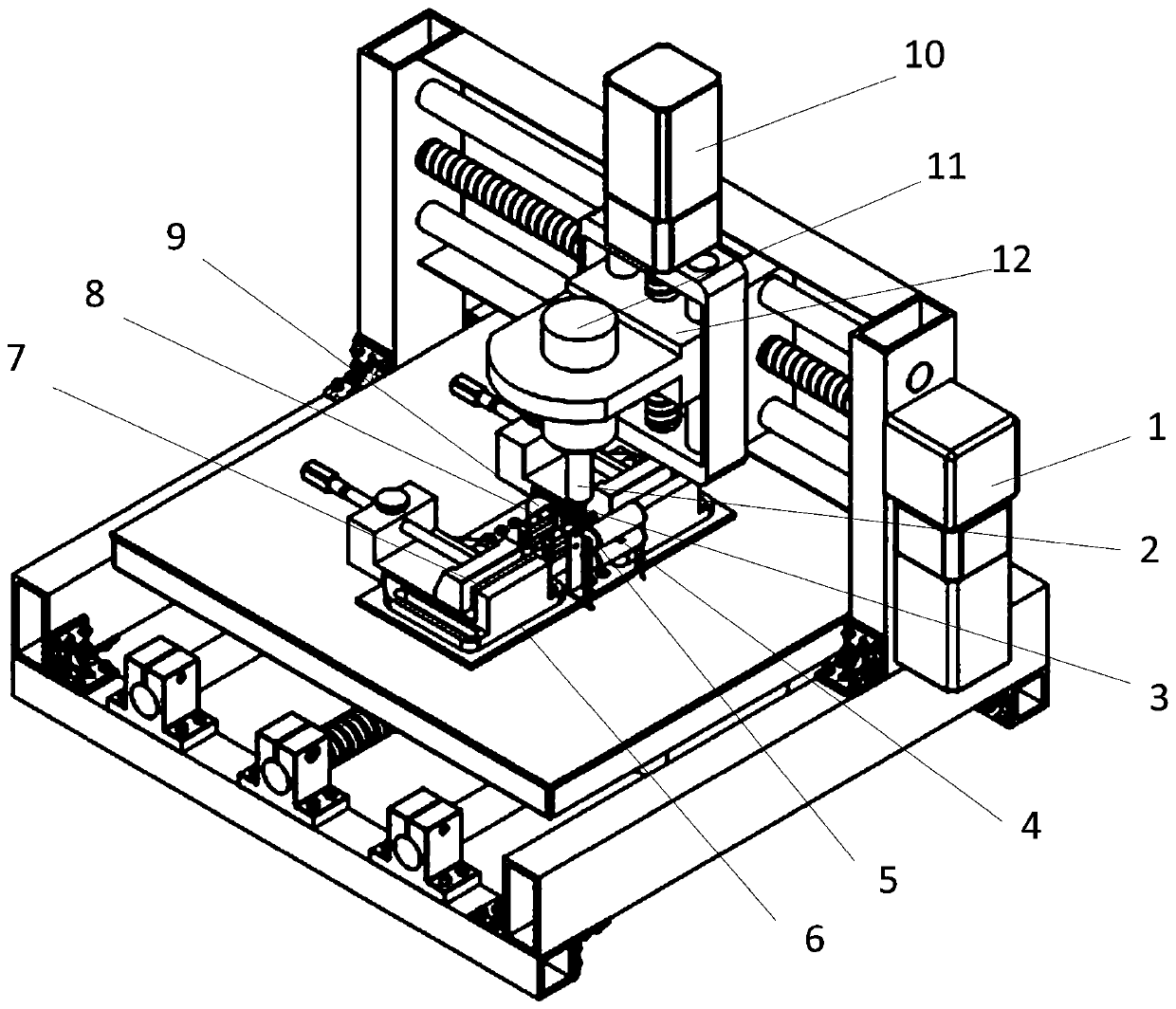

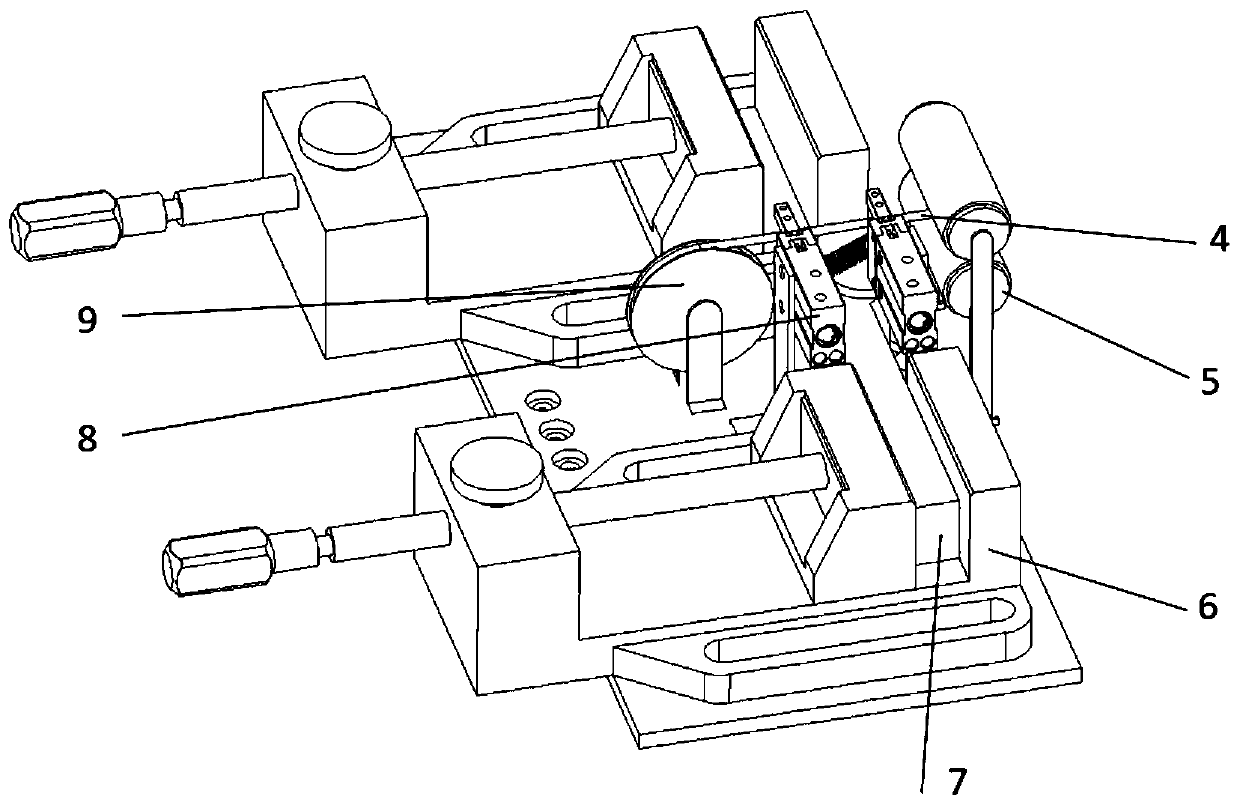

[0041] Step 2. First, fix the vibration exciter 1 with a frequency of 100 Hz and an amplitude of 0.1 mm on the Z-axis slider 12 of the single-point diamond three-dimensional drive mechanism of the vibrating single-point diamond imprinting instrument, and place the output rod of the vibration exciter 1 It is fixedly connected with the tool handle 2 inlaid w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com