Assembly type broach

An assembled and blade technology, which is applied to broaches, broaching machines, metal processing equipment, etc., can solve the problems of difficult machining of carbide broaches, achieve the effects of reducing material costs, facilitating installation and disassembly, and improving precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

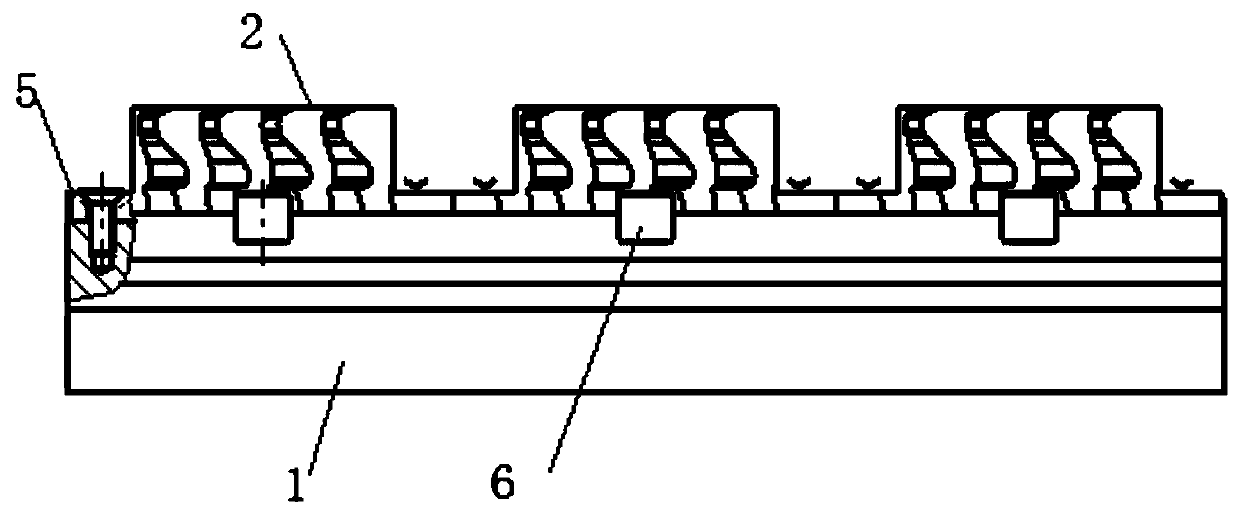

[0038] refer to Figure 1-9 , an assembled broaches, including a cutter body 1, and a blade group installed on the top thereof.

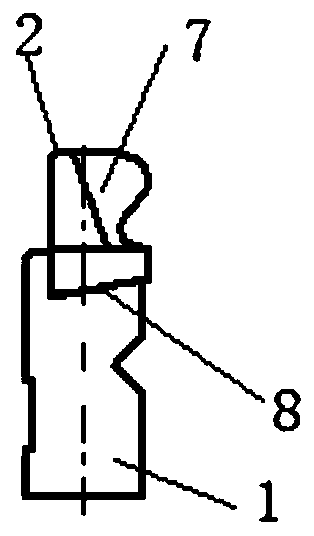

[0039] Wherein, the top of the cutter body 1 is provided with a positioning groove 12 , and the blade group is installed in the positioning groove 12 along the axial direction of the positioning groove 12 .

[0040] The blade set includes a plurality of blades, which are installed in the positioning groove 12 in turn. Each blade includes a base and a forming part on its top. Fastening parts 5 are respectively arranged at both ends of the base, and the blades are fixed by the fastening parts 5. Connected to the positioning groove 12.

[0041] The number of blades is 2-6.

[0042] refer to image 3 , the cross-section of the positioning groove 12 is an L-sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com