Integrally-mounted bridge cable laying method

A cable laying and self-contained technology, which is applied in the direction of cable laying equipment, etc., can solve the problems of limited operating space for operators, prone to safety accidents, and difficulty in ensuring construction quality, so as to reduce the time and frequency of high-altitude operations and reduce safety. The probability of accidents and the effect of improving the level of risk management and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

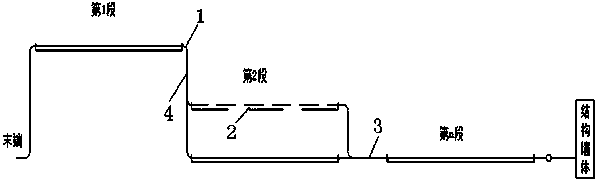

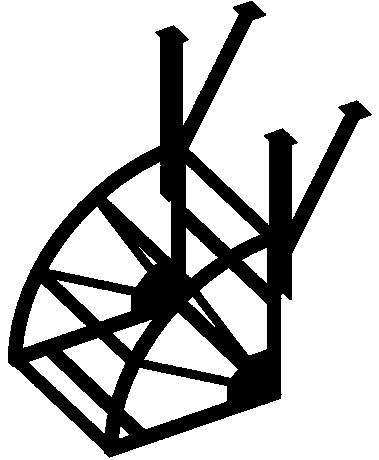

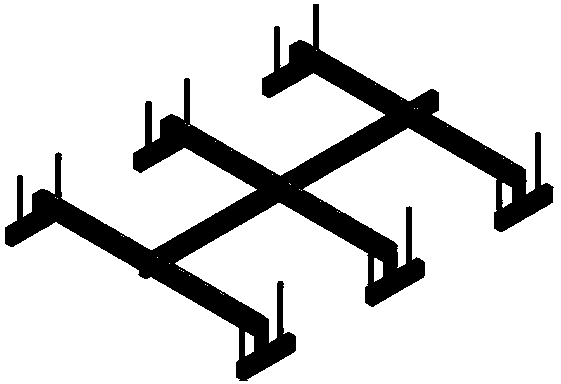

[0026] Such as Figure 1-6 Shown: a cable laying method for a self-contained cable tray, including the following steps:

[0027] Step 1: Apply pipeline comprehensive technology to plan the laying path of the cable tray as a whole, determine the direction of the relevant cables, and hoist the bridge into sections;

[0028] Step 2: According to the installation position of the support and hanger, take holes in the corresponding position of the roof and install the expansion bolts, which are used for the expansion bolt installation device of the high and far wall;

[0029] Step 3: Connect, segment, and straighten the bridge frame on the ground, install the bracket according to the position determined by the pipeline comprehensive technology, and fix it with the bridge frame, except for the first section which is installed according to the vertical projection of the pre-installed position, and adjacent to it The connected sections are all installed according to the floor height d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com