Preparation method of silver nanowire film

A technology of silver nanowires and thin films is applied in the field of preparation of silver nanowire thin films, and can solve the problems of poor uniformity of anisotropic impedance of silver nanowire thin films and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

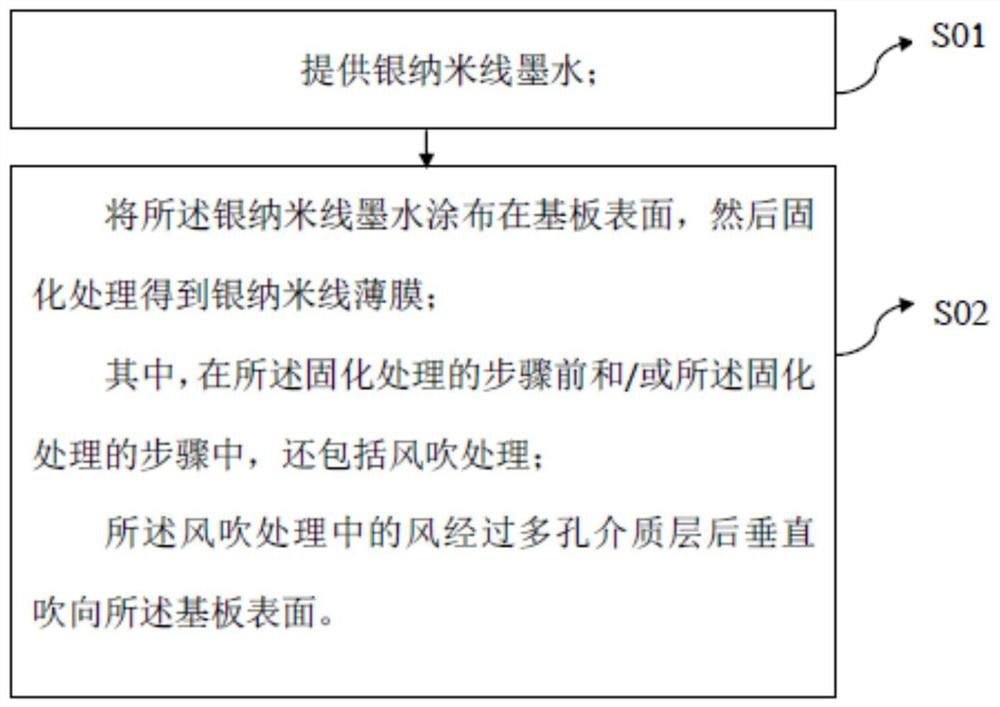

[0034] The embodiment of the present invention provides a kind of preparation method of silver nanowire thin film, such as figure 1 shown, including the following steps:

[0035] S01: Provide silver nanowire ink;

[0036] S02: coating the silver nanowire ink on the surface of the substrate, and then curing to obtain a silver nanowire film;

[0037] Wherein, before the step of curing treatment and / or during the step of curing treatment, wind blowing treatment is also included;

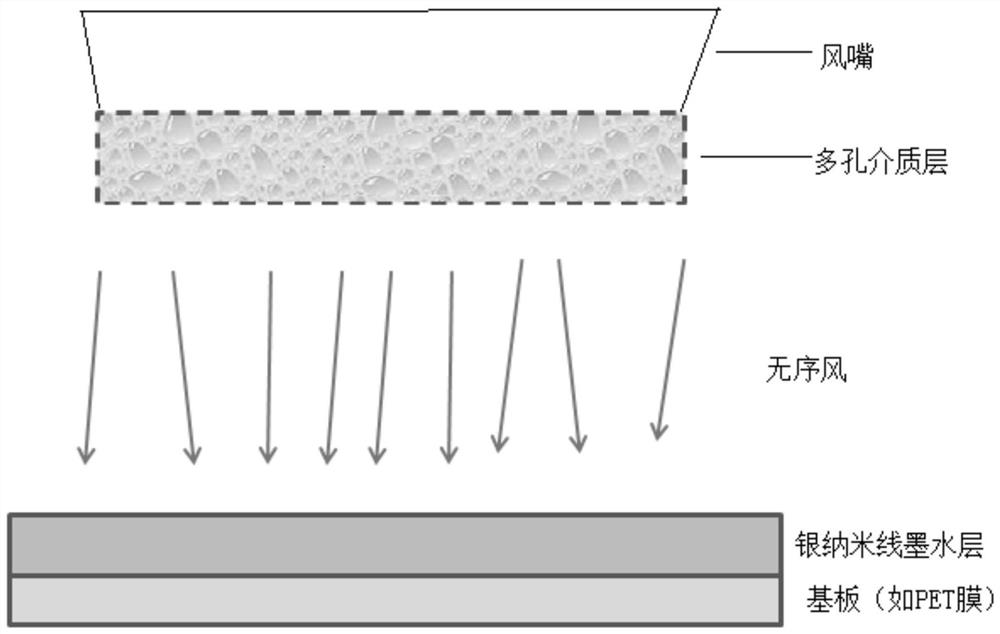

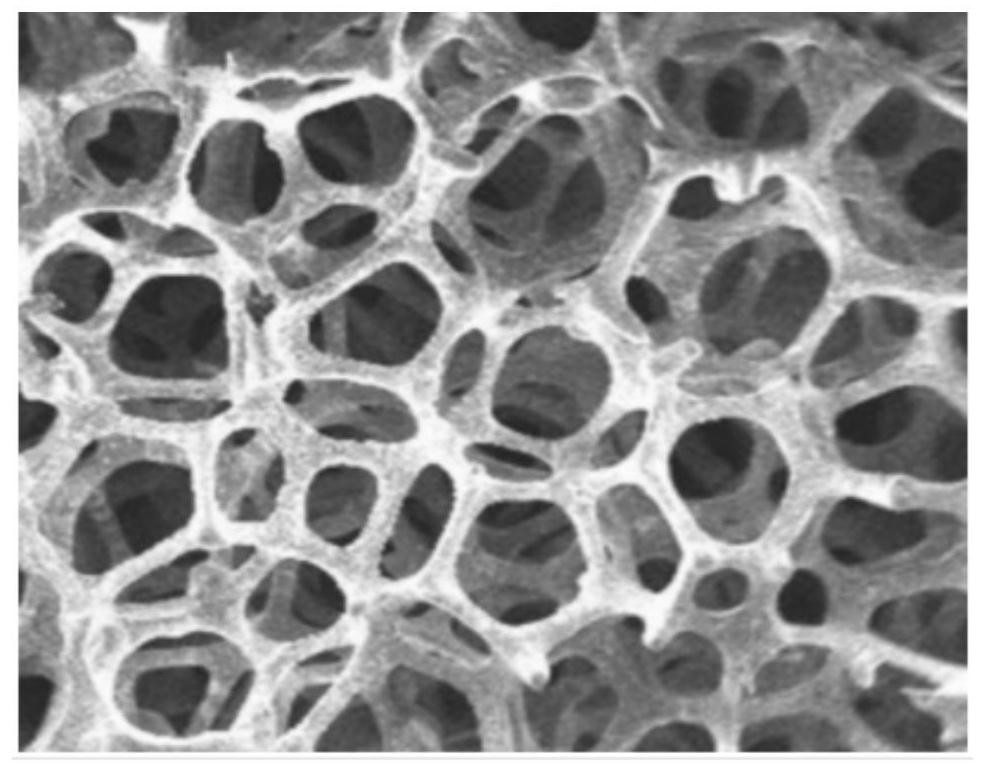

[0038] The wind in the wind blowing treatment is blown vertically to the surface of the substrate after passing through the porous medium layer.

[0039] In the preparation method of the silver nanowire film provided in the embodiment of the present invention, after the silver nanowire ink is coated on the surface of the substrate, the wind passing through the porous medium layer is blown vertically to the surface of the substrate coated with the silver nanowire ink. Because the wind coming out of th...

Embodiment 1

[0053] S11: Provide silver nanowire ink;

[0054] S12: Coating the silver nanowire ink on the surface of the substrate (PET film), and transporting the substrate coated with the silver nanowire ink to a tunnel furnace (a tuyere is installed at a height of 0.1 m at the front end of the tunnel furnace, The air outlet of the air nozzle is provided with a porous medium layer, and the porous medium layer is parallel to the substrate);

[0055] S13: Pass nitrogen gas into the tuyeres, which contains 1mmol / L hydrogen sulfide. The wind blows vertically to the surface of the substrate coated with the silver nanowire ink after passing through the porous medium layer, the wind speed is 1.8m / s, and the air volume is 1.8m 3 / s, the temperature is 130°C, the wind blows for 1min, and then solidifies to obtain a silver nanowire film.

Embodiment 2

[0057] S21: Provide silver nanowire ink;

[0058] S22: Coat the silver nanowire ink on the surface of the substrate (PET film), and transfer the substrate coated with the silver nanowire ink to a tunnel furnace (the front end of the tunnel furnace is equipped with an air nozzle at a height of 1 m, The air outlet of the nozzle is provided with a porous medium layer, and the porous medium layer is parallel to the substrate);

[0059] S23: Pass air with humidity 3 / s, the temperature is 150°C, the wind blows for 2 minutes, and then solidifies to obtain a silver nanowire film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com