Preparation method of silver nanowire film

A technology of silver nanowires and thin films is applied in the field of preparation of silver nanowire thin films, and can solve the problems of poor uniformity of anisotropic impedance of silver nanowire thin films and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

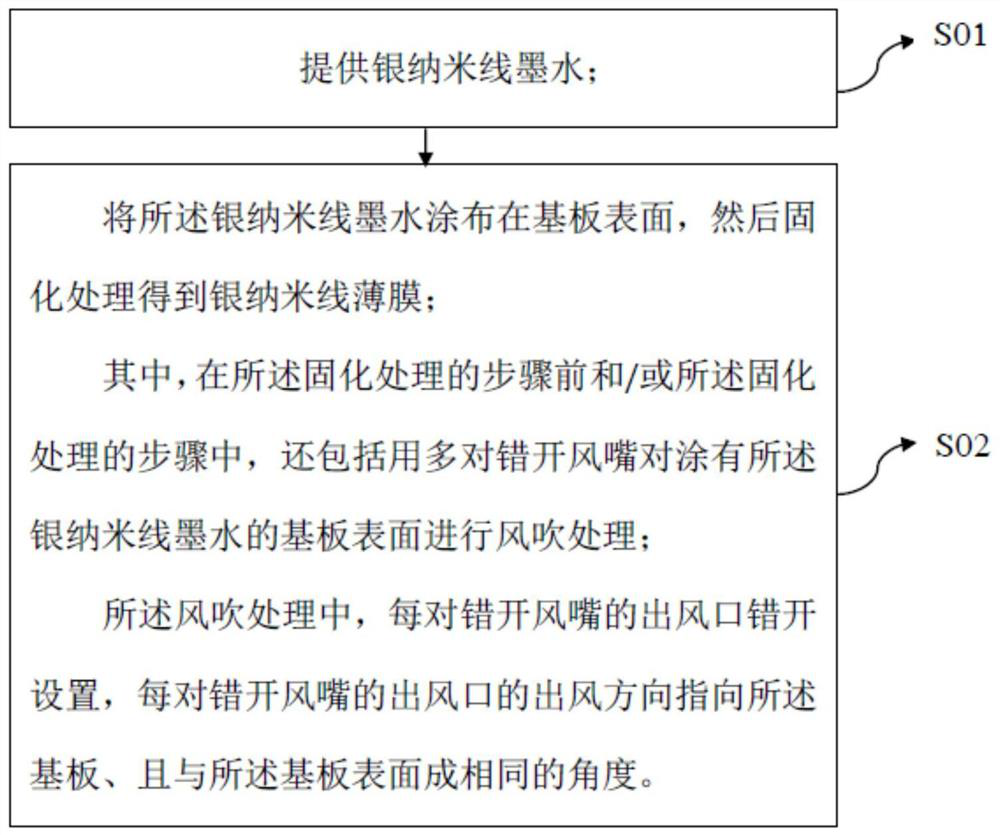

[0038] On the one hand, the embodiment of the present invention provides a kind of preparation method of silver nanowire film, such as figure 1 shown, including the following steps:

[0039] S01: Provide silver nanowire ink;

[0040] S02: coating the silver nanowire ink on the surface of the substrate, and then curing to obtain a silver nanowire film;

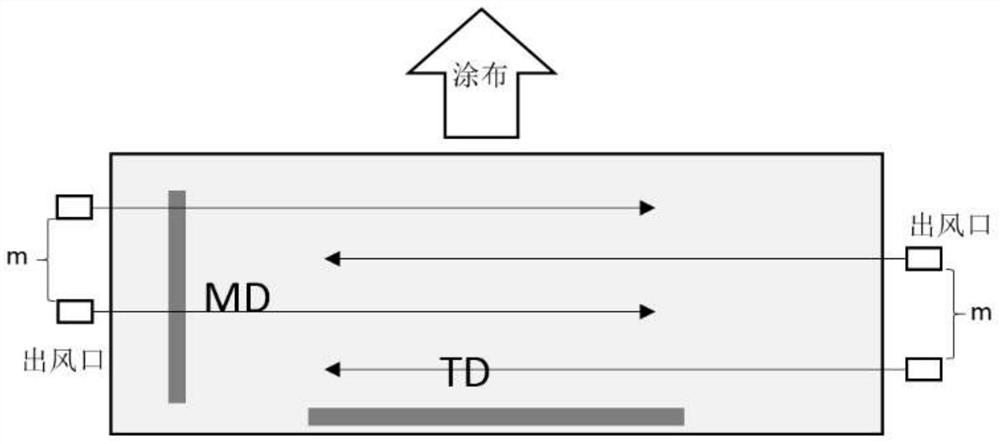

[0041] Wherein, before the step of the curing treatment and / or during the step of the curing treatment, it also includes using multiple pairs of staggered air nozzles to perform wind blowing treatment on the surface of the substrate coated with the silver nanowire ink;

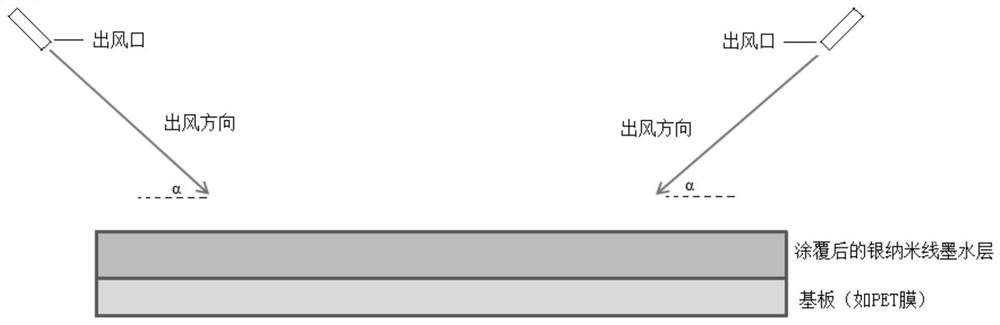

[0042] In the wind blowing process, the air outlets of each pair of staggered tuyere nozzles are arranged in a staggered manner, and the air outlet direction of each pair of staggered air nozzles points to the substrate and forms the same angle with the surface of the substrate.

[0043] In the preparation method of the silver nanowire thin film provided by t...

Embodiment 1

[0063] A method for preparing a silver nanowire film, comprising the steps of:

[0064] S11: Provide silver nanowire ink;

[0065] S12: Coat the silver nanowire ink on the surface of the substrate (PET film), and transfer the substrate coated with the silver nanowire ink to a tunnel furnace (the front end of the tunnel furnace is equipped with 5 pairs of staggered air nozzles, so The air outlet direction of the staggered air outlet of the staggered air nozzle points to the substrate and forms an angle of 10° with the substrate, the width of the air outlet of the staggered air nozzle is 3cm, and the air outlet of the staggered air nozzle The vertical distance of the substrate is 10cm, and the distance between the same-side air outlets of the air outlets of the staggered air nozzles is 50cm);

[0066] S13: Pass nitrogen gas into the staggered tuyeres, which contains 2 mmol / L hydrogen sulfide. The surface of the substrate coated with the silver nanowire ink is blown by wind for...

Embodiment 2

[0068]A method for preparing a silver nanowire film, comprising the steps of:

[0069] S11: Provide silver nanowire ink;

[0070] S12: Coat the silver nanowire ink on the surface of the substrate (PET film), and transfer the substrate coated with the silver nanowire ink to a tunnel furnace (the front end of the tunnel furnace is equipped with 5 pairs of staggered air nozzles, so The air outlet direction of the staggered air outlet of the staggered air nozzle points to the substrate and forms an angle of 30° with the substrate. The width of the air outlet of the staggered air nozzle is 10 cm. The vertical distance of the substrate is 50cm, and the distance between the same-side air outlets of the air outlets of the staggered air nozzles is 30cm);

[0071] S13: Pass air into the staggered tuyeres, which contains 0.5 mmol / L hydrogen sulfide. The surface of the substrate coated with the silver nanowire ink was blown for 5 minutes, the wind speed was 2.1m / s, and the air volume wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com