Water supply and preheating system and method for turbogenerator applied to medium pressure deaerator

A technology for turbogenerators and deaerators, applied in the field of deaerators, can solve the problems of low deoxygenation efficiency of medium-pressure deaerators, and achieve the effects of reducing heat loss, good fixing effect, and tight connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

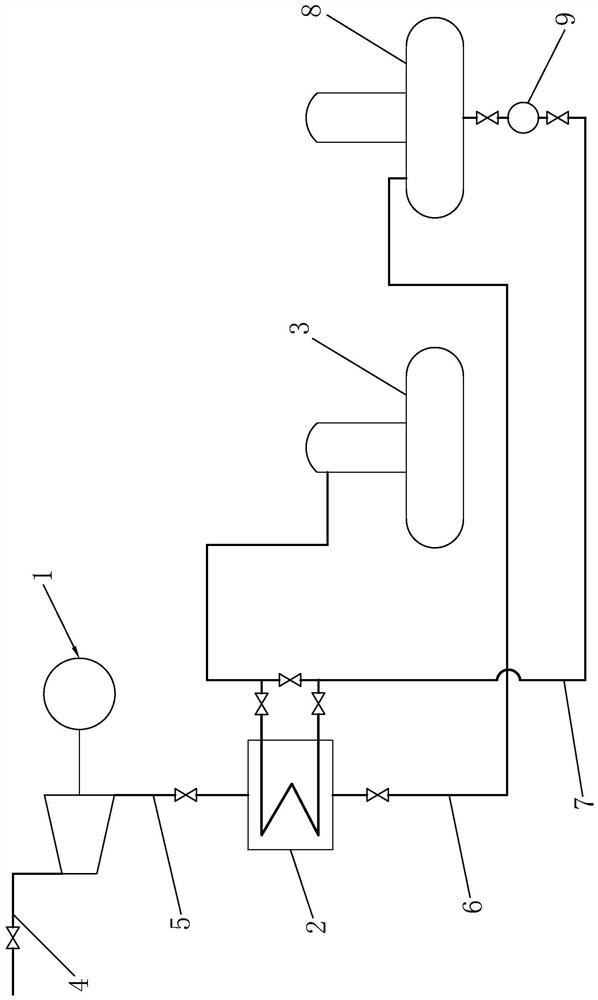

[0043] Such as Figure 1 to Figure 10 As shown, it is the water replenishment preheating system applied to the medium-pressure deaerator by the steam turbine generator of the present invention, including a decompression mechanism 1, a surface heat exchanger 2 and a medium-pressure deaerator 3, and the decompression mechanism 1 is provided with an advanced Steam pipe 4 and exhaust pipe 5, exhaust pipe 5 is connected with surface heat exchanger 2, surface heat exchanger 2 is provided with drain pipe 6, medium pressure deaerator 3 is provided with water supply pipe 7, water supply pipe 7 Connected with the surface heat exchanger 2, an atmospheric deaerator 8 is provided between the drain pipe 6 and the water supply pipe 7, and a relay pump 9 is provided on the water supply pipe 7. Reduce the pressure of the heating steam through the decompression mechanism 1, and utilize the pressure drop of the heating steam at the same time to improve the utilization rate of energy. The surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com