Gearbox for spraying machine

A gearbox and sprayer technology, applied in the direction of mechanical equipment, gear transmission, transmission control, etc., can solve the problems of gearbox usage restrictions, inconvenient lubrication of parts, and unsatisfactory parts, and achieve a wide range of output torque and speed , The structure and assembly process are simple, and the effect of reducing the assembly connection space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047]Embodiment 1 A kind of gearbox for sprayer

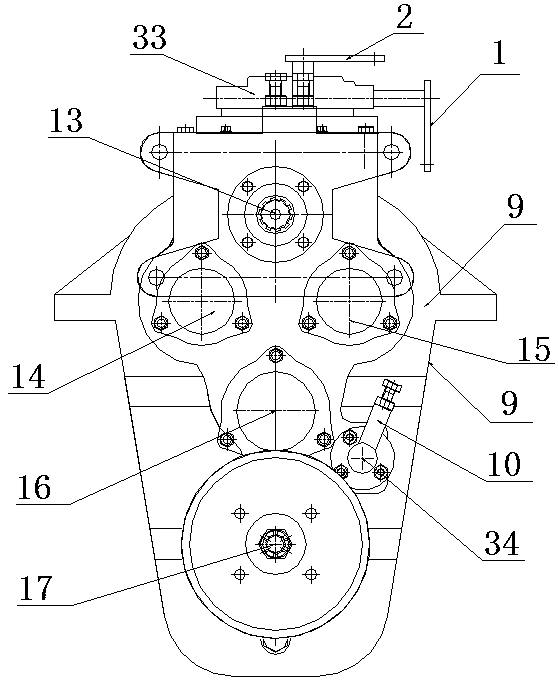

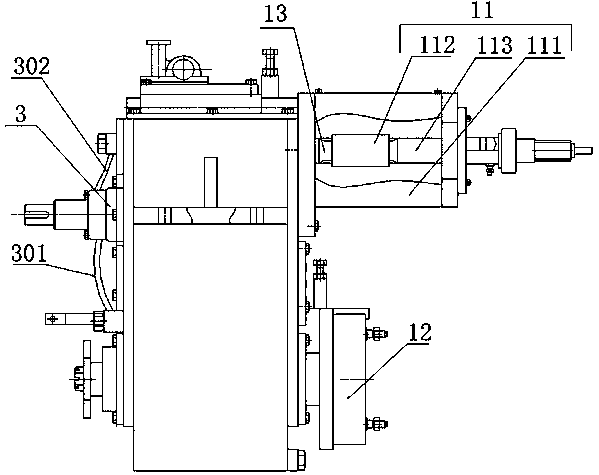

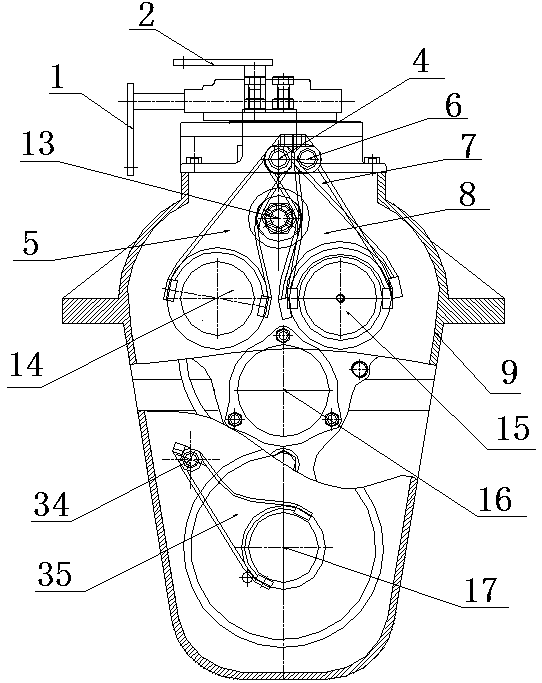

[0048] Such as Figure 1-5 As shown, the present invention provides a gearbox for a sprayer, including a casing 9, a power input shaft 13, a third transmission shaft 16 and a power output shaft 17 are arranged from top to bottom in the casing 9, and the power The input shaft 13, the third transmission shaft 16 and the power output shaft 17 are arranged facing up and down; the first transmission shaft 14 and the second transmission shaft 15 which are symmetrical to each other are arranged between the power input shaft 13 and the third transmission shaft 16; The first transmission shaft 14 and the second transmission shaft 15 are arranged on the same level.

[0049] The power input shaft 13 , the first transmission shaft 14 , the second transmission shaft 15 , the third transmission shaft 16 and the power output shaft 17 are all rotatably connected to the side wall of the box body 9 through bearings 18 .

[0050] The input end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com