Fabricated shear wall with steel plate stud combined type diagonal bracing and construction method

A shear wall and combined technology, applied to walls, building components, buildings, etc., can solve the problems of high technical level requirements for on-site construction personnel, increase the difficulty of on-site construction, and difficulty in ensuring welding quality, etc., to achieve enhanced collaborative work, Improve construction speed and facilitate hoisting and combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

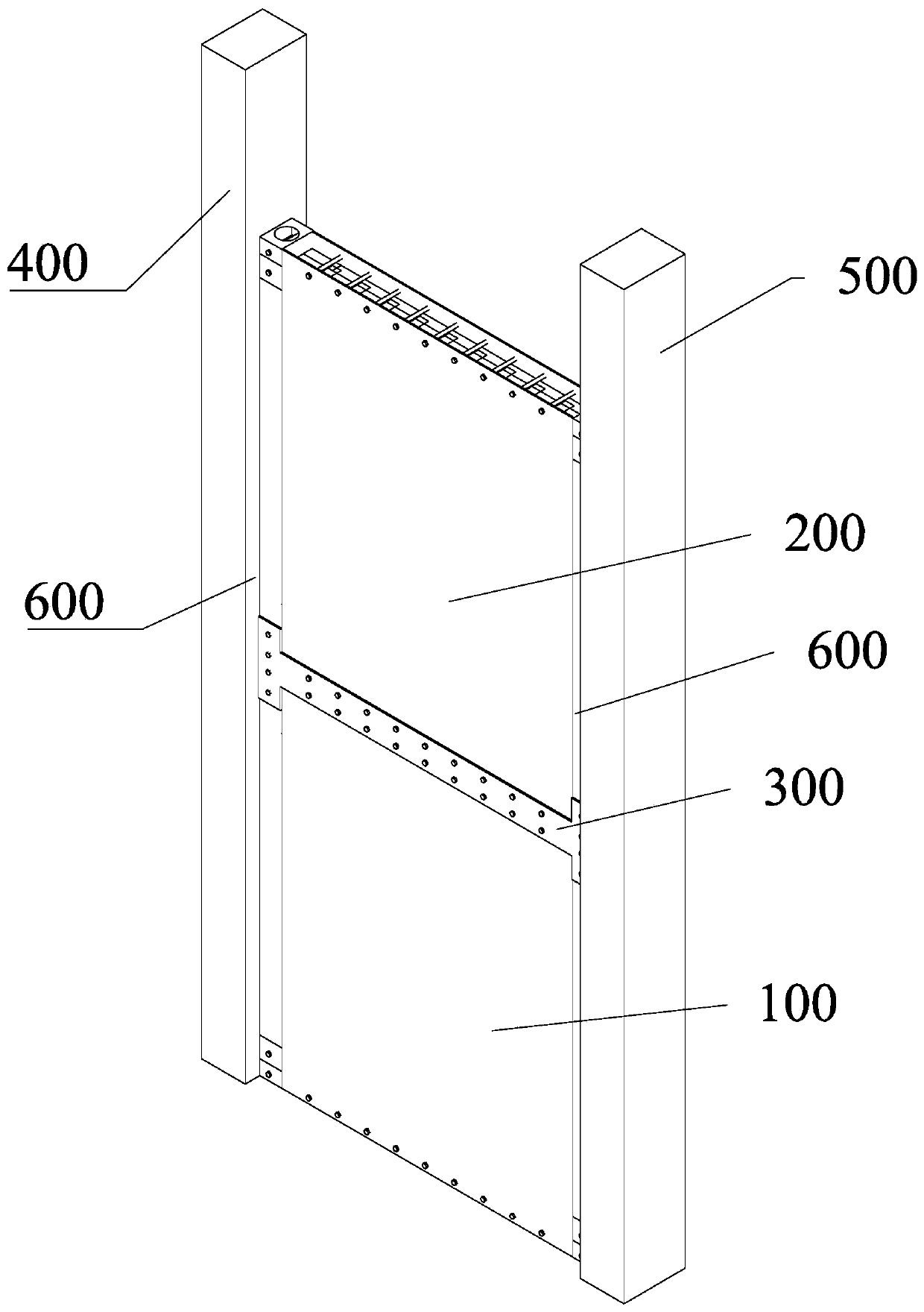

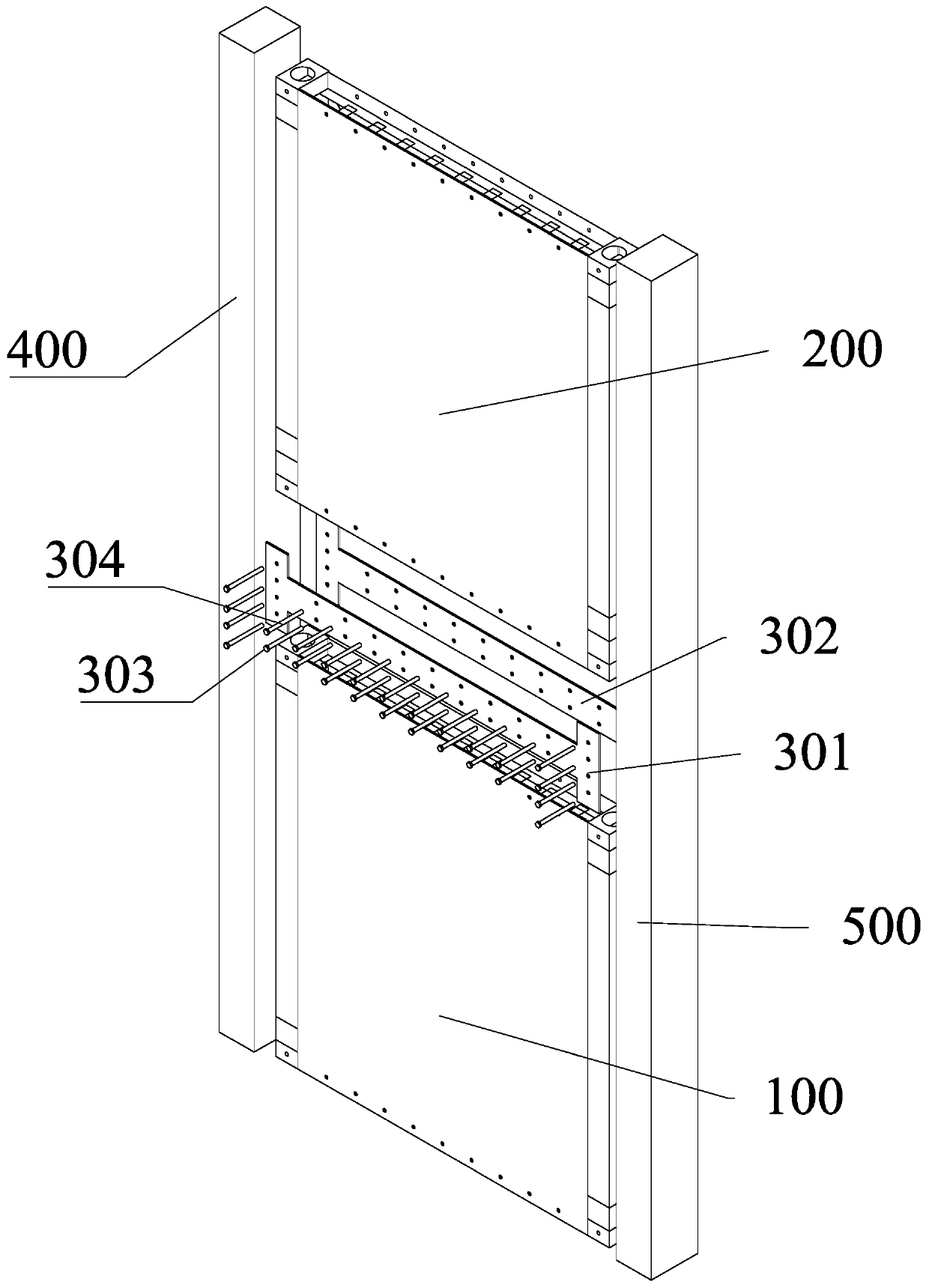

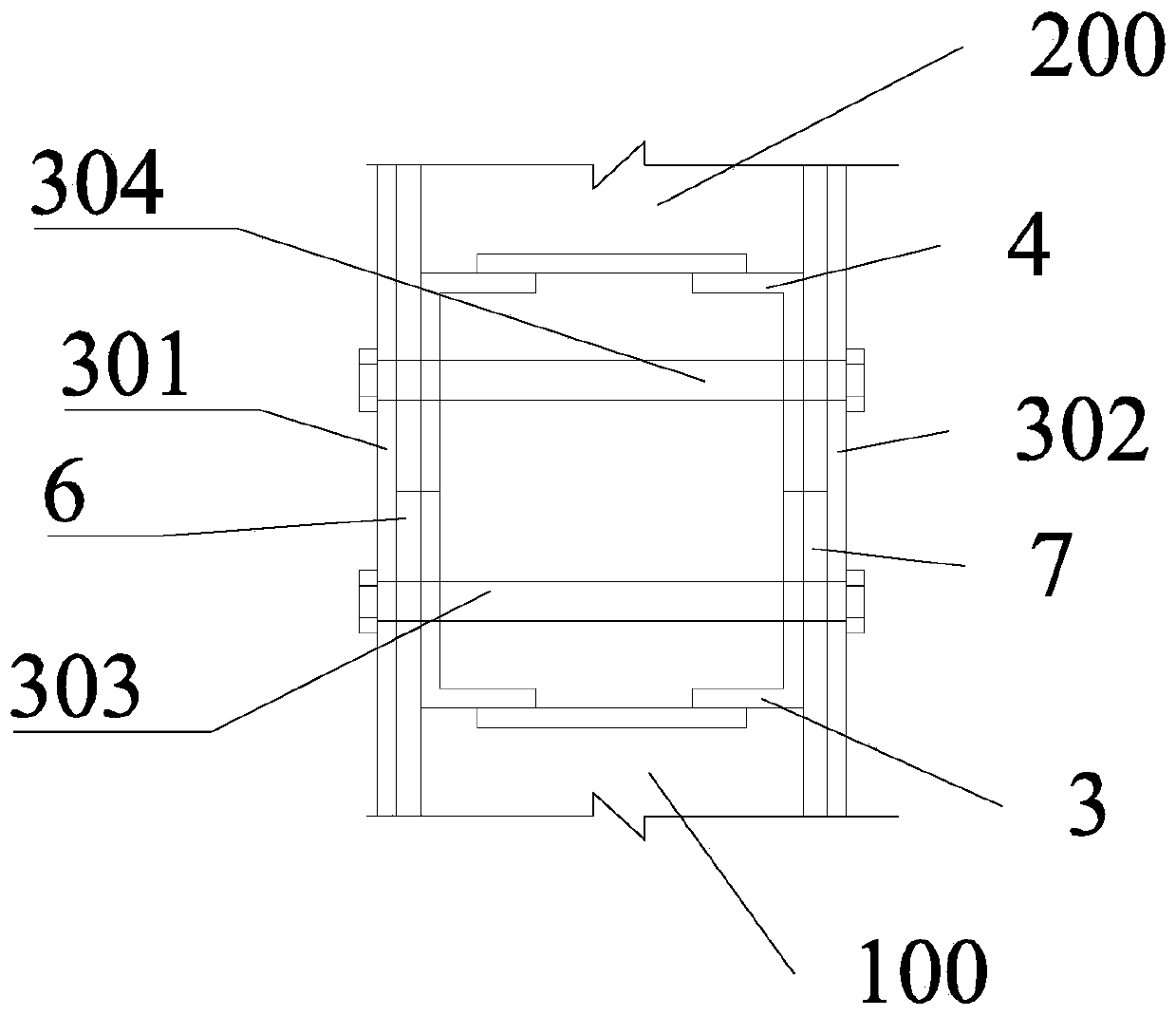

[0049] Such as Figure 1-4 As shown, a prefabricated shear wall with a steel plate stud combined diagonal brace according to a preferred embodiment of the present invention includes a first shear wall unit 100, a second shear wall unit 200 and a connecting mechanism 300;

[0050] The first shear wall unit 100 and the second shear wall unit 200 are stacked up and down and connected and fixed by a connection mechanism 300, wherein the second shear wall unit 200 is located on the upper side of the first shear wall unit 100 The connecting mechanism 300 includes a first connecting plate 301 and a second connecting plate 302; the first connecting plate 301 is used to connect and fix the front side of the first shear wall unit 100 and the front side of the second shear wall uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com