A kind of waste paper casing soaking water shredding machine for straw paper making

A shredder and paper shell technology, which is applied in papermaking, paper recycling, textiles and papermaking, etc., can solve the problems of slow shredding, uneven and unfavorable waste paper shells, and achieve the effect of accelerating the shredding speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

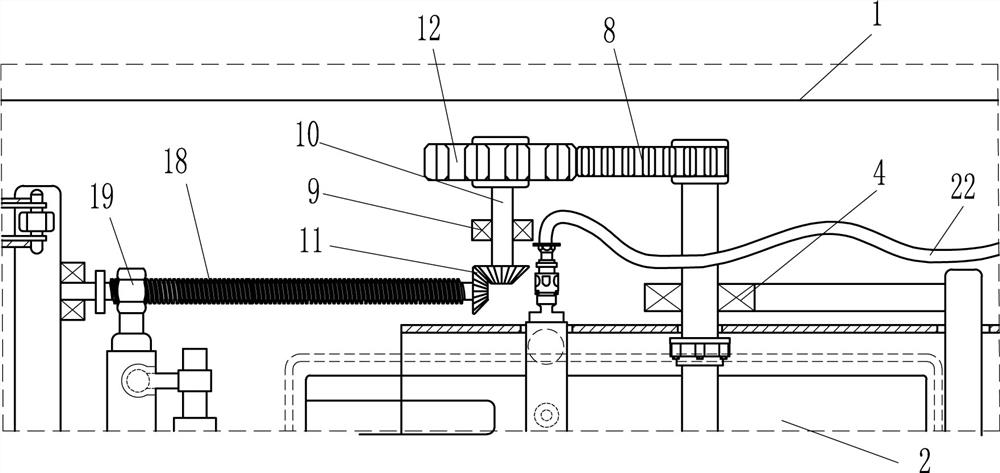

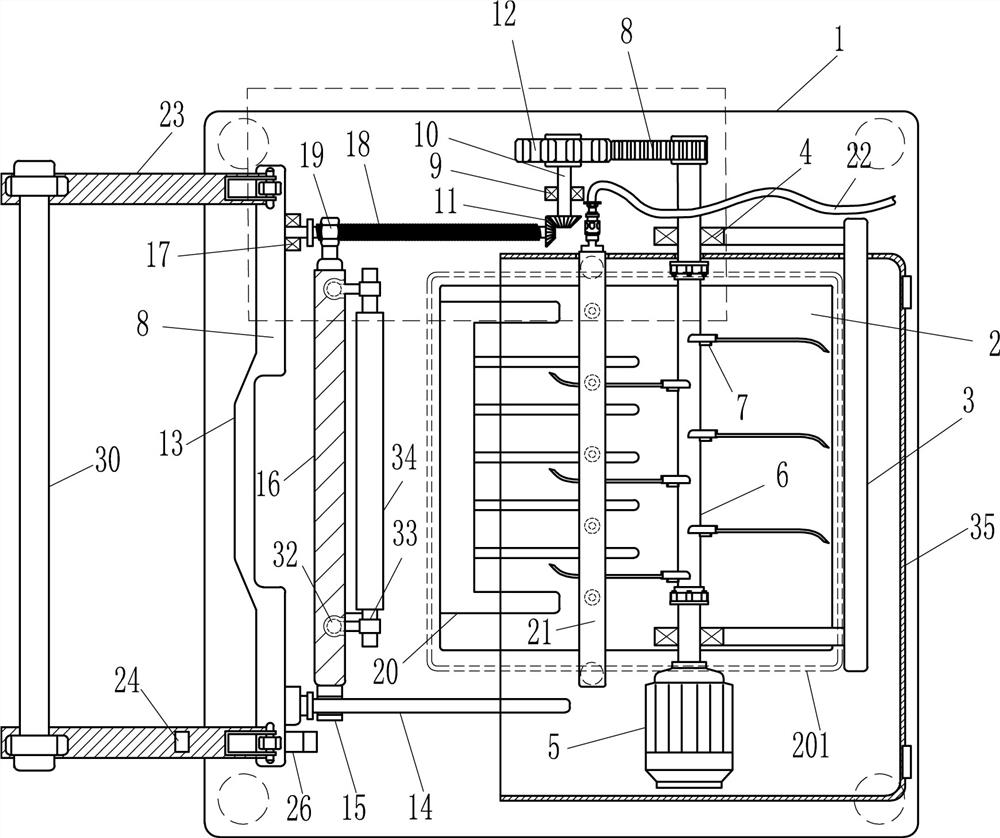

[0020] A kind of straw paper making machine of this embodiment is soaked in water with waste paper shells, such as Figure 1-3 As shown, it includes a table body 1, a vertical plate 3, a cutting device, a transmission device, a pushing device, a placement plate 20, a collection frame 201, a nozzle 21, a flexible pipe 22 and a pressing device. Opening 2, the right part of the table body 1 is provided with a vertical board 3, the vertical board 3 is provided with a cutting device for cutting waste paper shells, the rear side of the top of the table body 1 is provided with a transmission device for transmitting power, and the left part of the table body 1 is provided with a There is a pushing device to push the waste paper shell to move to the right. There is a placement plate 20 in the left part of the opening 2. A collection frame 201 is placed at the bottom of the table body 1. The collection frame 201 is located under the opening 2. A nozzle 21 is provided in the middle of the...

Embodiment 2

[0023] like Figure 1-2 As shown, the transmission device includes a sector gear 8, a second bearing seat 9, a second rotating shaft 10, a bevel gear 11 and a ring gear 12, the rear side of the first rotating shaft 6 is provided with a sector gear 8, and the rear side of the top of the table body 1 is passed through a bolt A second bearing seat 9 is fixedly connected, and a second rotating shaft 10 is interferentially connected in the second bearing seat 9. A bevel gear 11 meshing with each other is provided on the front side of the second rotating shaft 10 and the pushing device, and a bevel gear 11 is provided on the rear side of the second rotating shaft 10. There is a ring gear 12 which meshes with the sector gear 8 . Specifically, when the cutting device is started, the rotation of the first rotating shaft 6 drives the sector gear 8 to rotate; The rotating shaft 10 rotates, and the second rotating shaft 10 rotates to drive the bevel gear 11 to rotate, and the bevel gear ...

Embodiment 3

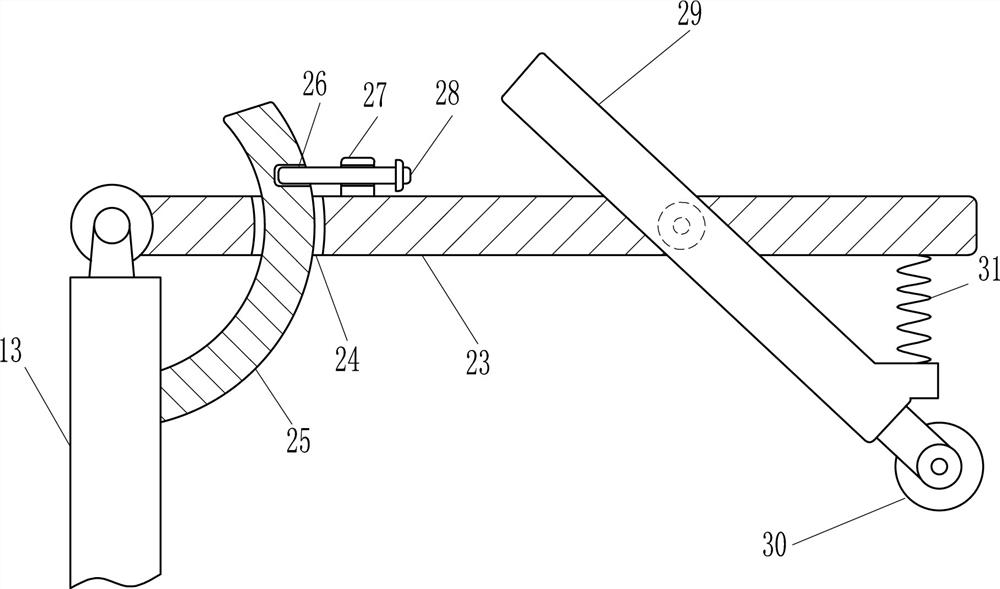

[0026] like figure 1 and image 3 As shown, the pressing device includes a first support rod 23, an arc-shaped guide rod 25, a guide sleeve 27, an insertion rod 28, a second support rod 29, a first roller 30 and an elastic member 31, and the front and rear sides of the top of the mounting plate 13 are The uniform rotation type is provided with a first support rod 23, and the first support rod 23 on the front side is provided with an arc-shaped chute 24, and the front part of the mounting plate 13 is provided with an arc-shaped guide rod 25, and the arc-shaped guide rod 25 is located in the arc-shaped chute 24, the arc guide rod 25 top has a slot 26, the first pole 23 on the front side is provided with a guide sleeve 27, the guide sleeve 27 is slidingly provided with an insertion rod 28, and the insertion rod 28 is inserted in the slot 26, The front side of the first pole 23 on the front side and the rear side of the first pole 23 on the rear side are all rotatably provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com