Method for preparing polyisocyanate by photochemical reaction and method for preparing waterborne polyurethane resin

A polyisocyanate, reaction technology, applied in the field of water-based polyurethane resin, can solve the problems of high chlorine content of polyisocyanate, yellow color and other problems, achieve the effect of improving yellowing resistance, reducing violent fluctuations, and improving yellowing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

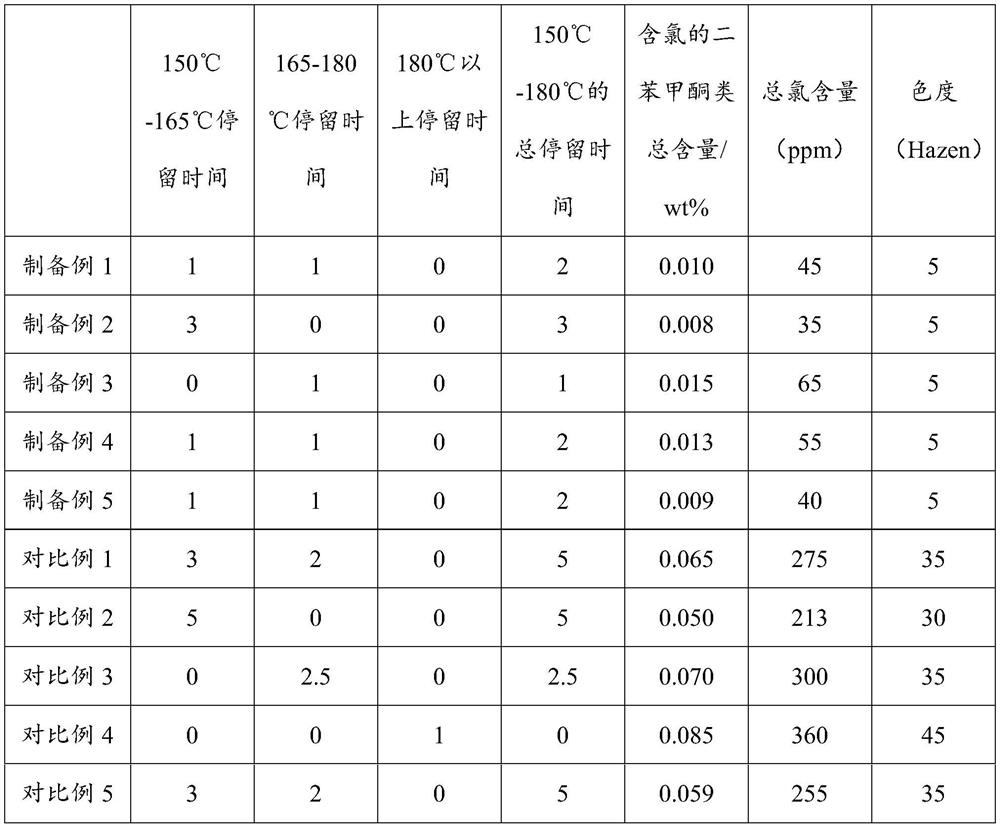

preparation example 1

[0098] a) using the heater disclosed in Example 1 of Chinese patent application CN105214568A, a diamine H 12 MDA is gasified and heated to 355 deg.] C, under nitrogen protection, and gaseous phosgene is heated to 355 deg.] C via a respective feed line continuously added phosgenation reactor; absolute pressure of the reaction is 0.05MPa, the reaction temperature is 360 deg.] C; wherein, H 12 MDA feeding amount is 800Kg / h, the feed amount of the gaseous phosgene was 3000Kg / h; using o-dichlorobenzene solution through a gas injection means for absorbing the reaction mixture obtained after the flash gas (contact time of approximately 10s) was cooled to 100 ℃, to give product containing H 12 MDI, crude product phosgene and a solution of o-dichlorobenzene; o-dichlorobenzene solution absorption -35 ℃ the absorber off-gas entering the exhaust gas after the reaction to give the o-dichlorobenzene solution of phosgene.

[0099] b) step a) obtained crude product is treated to remove phosge...

preparation example 2

[0107] Step a) the phosgenation reaction is a liquid phase phosgenation, with reference to China Patent Document CN103319372B reactor disclosed in the following steps are performed:

[0108] 1) The cold reaction: the H 12 MDA o-dichlorobenzene as a solvent configured content of 15% by mass solution, and preheated to 40 ℃, liquid phase and the liquid phosgene -5 ℃ simultaneously introduced into the reaction vessel containing a solution of o-dichlorobenzene phosgenation; wherein, H 12 MDA in feed rate is 400Kg / h, cool the reaction of phosgene feed rate of 1500kg / h, cool the reaction temperature is controlled at 60 ℃, residence time of 5min;

[0109] 2) thermal reaction: temperature was controlled at 155 deg.] C, and a residence time of 2h, the reaction was carried out in o-dichlorobenzene and the presence of excess phosgene to give the product containing H 12 MDI, phosgene and o-dichlorobenzene solution of the reaction liquid (crude product);

[0110] O-dichlorobenzene solution ...

preparation example 3

[0118] Step a) using the phosgenation of a salt phosgenation reactor tank embodiments with reference to Chinese Patent Document CN105218422B Example 1 disclosed in the following steps are performed:

[0119] 1) In the salt-forming reaction kettle was added after previously 1000Kg o-dichlorobenzene as the reaction solvent, and stirring the circulating pump, the compressed gas is hydrogen chloride at a rate of 50mol / min into the reactor via a pre-mixer, stirring 15min, the H 12 MDA and o-dichlorobenzene by heating a mixture of starting material to a preheater 30 ℃, after sufficient contact to 335Kg / h and the flow rate of hydrogen chloride gas into a salt; using external circulating cooling water for cooling, removing part of the reaction heat, cycling liquid flow 5m 3 Left / h, the reaction solution temperature was maintained at 30-45 ℃, the feed 3h, stopping H 12 O-dichlorobenzene with MDA feed mixture, continuing to pass HCl gas 30min.

[0120] 2) step 1) obtained H 12 MDA hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com