A screw mold for cooling

A mold and screw technology, which is applied in the field of screw molds that are easy to cool, can solve the problems of low cooling efficiency and cooling, and achieve the effect of improving water cooling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

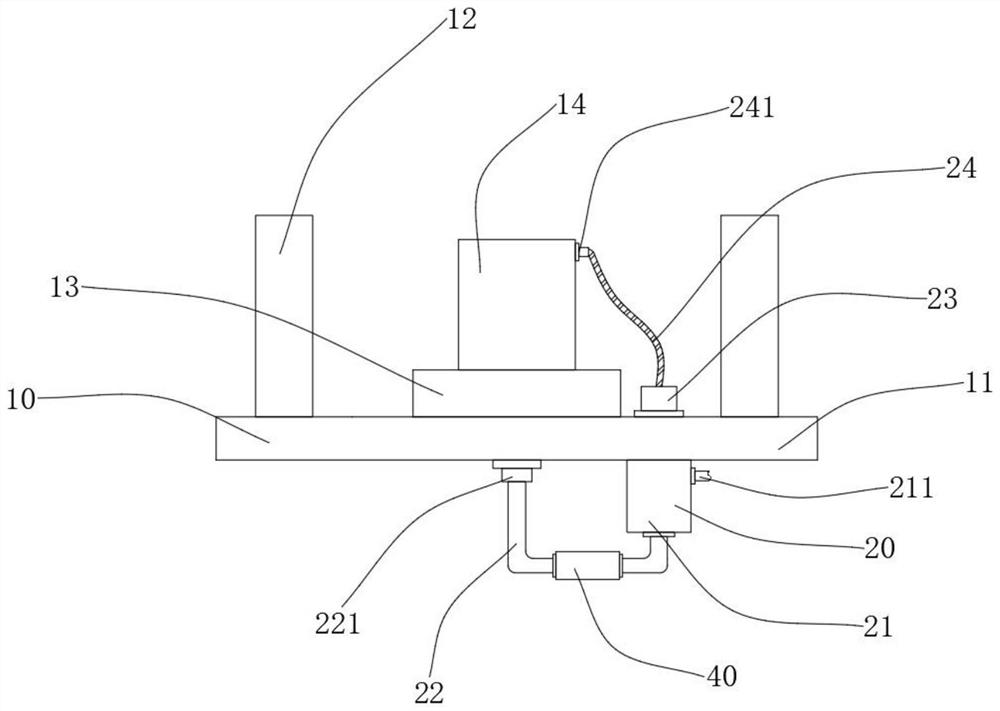

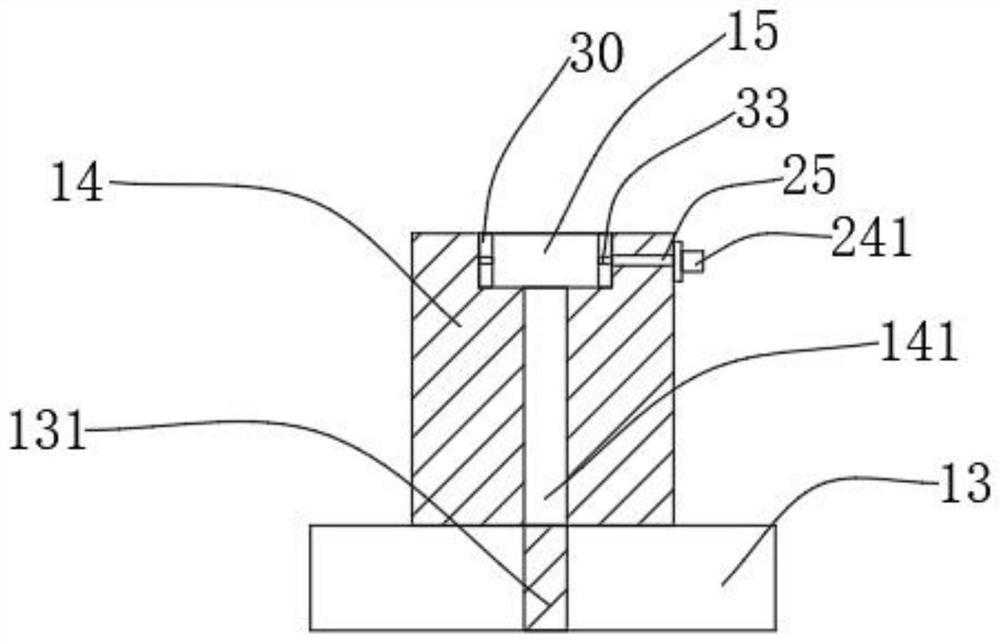

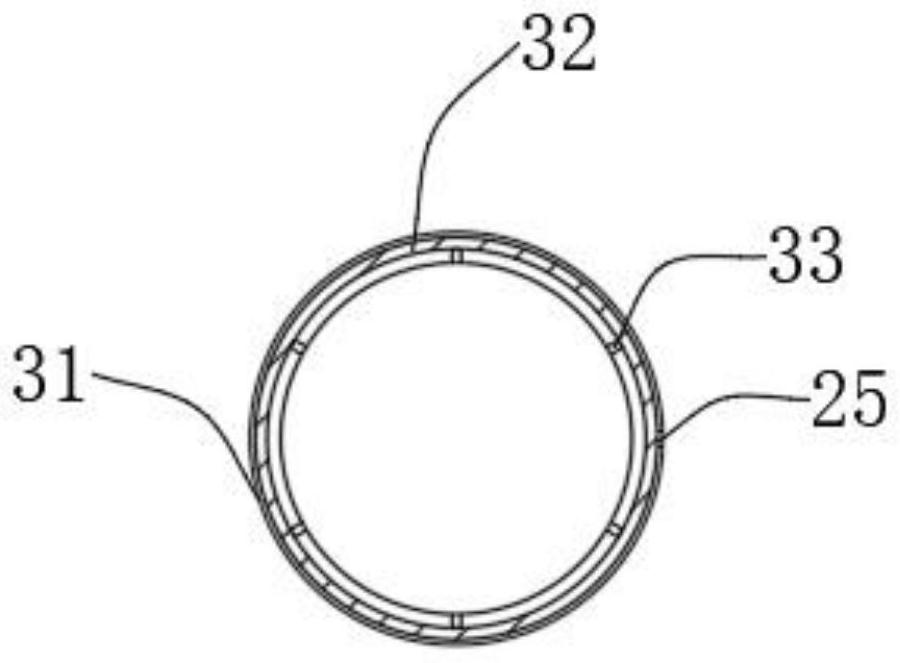

[0018] see Figure 1-4 , the present invention provides a technical solution: a convenient cooling screw mold, including a lower mold assembly 10, a circulation assembly 20, a water spray assembly 30 and a filter assembly 40, and the lower mold assembly 10 includes a lower mold base 11, Guide column 12, lower template 13, mold main body 14 and nut groove 15, described circulation assembly 20 comprises water tank 21, circulation pipe 22, miniature water pump 23, second water inlet pipe 24 and water inlet groove 25, described lower mold base 11 The bottom of the bottom of the water tank 21 is provided with the circulation pipe 22, the top of the lower mold base 11 is fixedly connected with the micro-water pump 23, and the water outlet of the micro-water pump 23 is provided with The second water inlet pipe 24, one end of the second water inlet pipe 24 is provided with the water inlet tank 25, the micro water pump 23 is electrically connected to an external power supply, the water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com