Adjustable water cooling tank for winding film blow molding processing

A water-cooled pool and adjustable technology, applied in the field of stretch film processing, can solve the problems of low cooling water utilization, energy waste, and reduced cooling efficiency, and achieve the effects of improving water cooling efficiency, increasing utilization, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

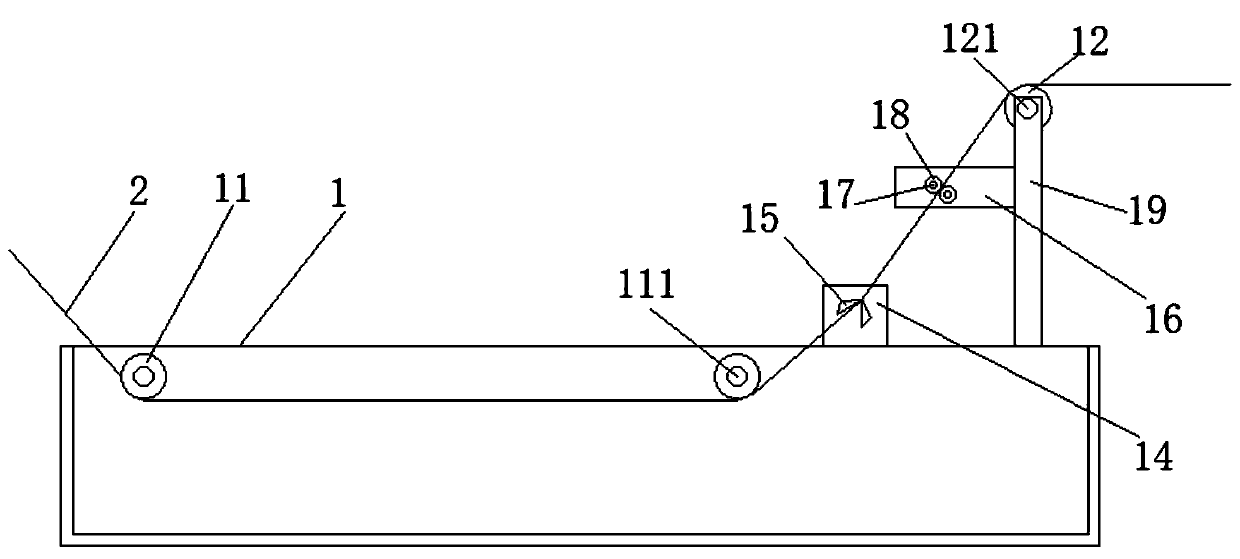

[0020] An adjustable water cooling pool for stretch film blow molding processing, comprising a water cooling pool 1, two rotatable water cooling rolls 11 are arranged in the water cooling pool 1, and the upper end of the water cooling pool 1 on one side of the water cooling roll 11 is provided with There is a discharge roller 12, and the two ends of the discharge roller 12 are fixed on the upper end of the water cooling pool 1 by fixing rods 19.

[0021] An adsorption roller 17 is arranged between the discharge roller 12 and the water-cooled roller 11, and there are two adsorption rollers 17, and the adsorption rollers 17 are close to each other but not in contact.

[0022] Utilizing the adsorption roller 17, the moisture on the surface of the stretched film 2 after water cooling can be effectively adsorbed, and the post-drying efficiency of the stretched film 2 is improved.

[0023] The two ends of the discharge roller 12 are movably connected with the fixed rod 19 through th...

Embodiment 2

[0026] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

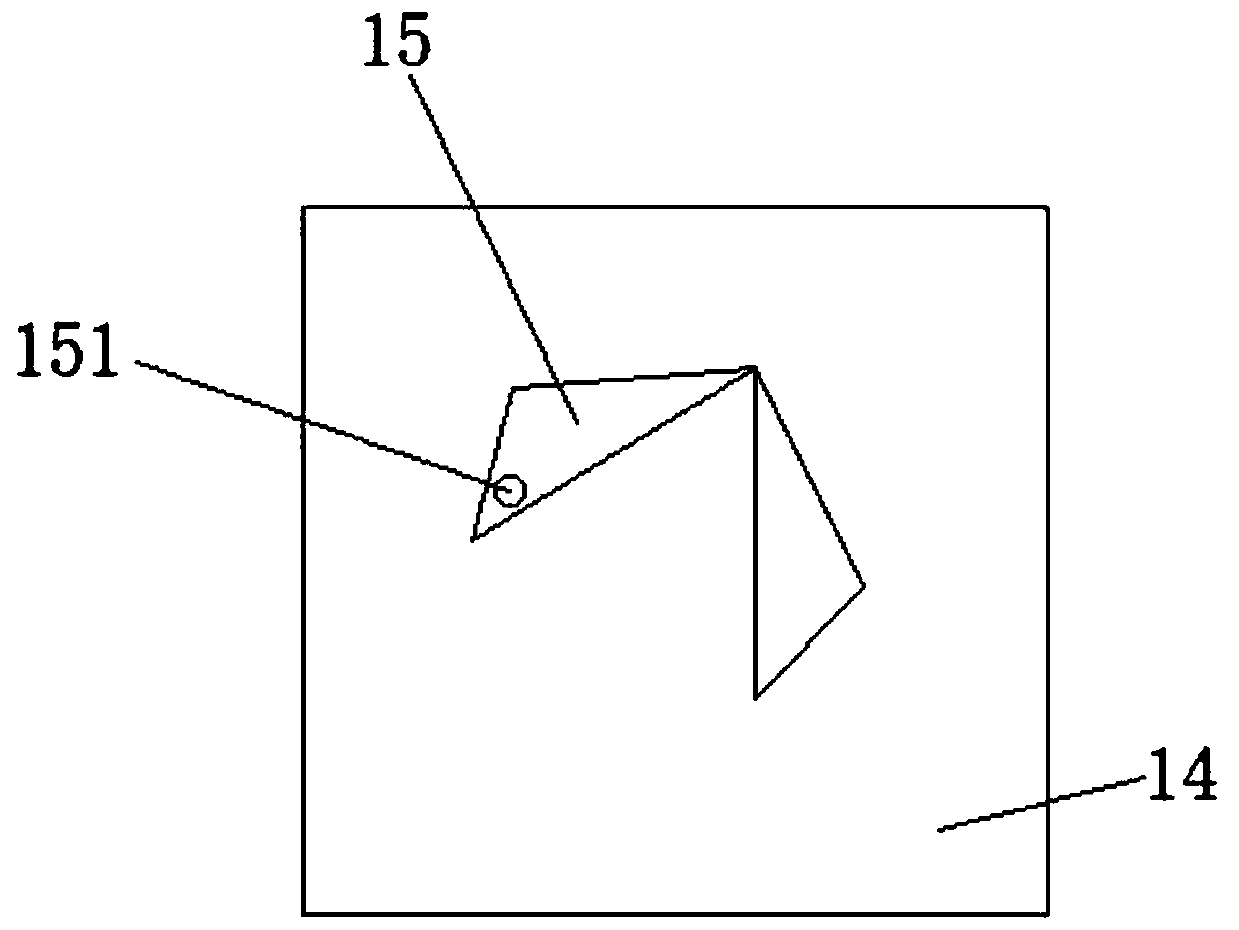

[0027] see Figure 1-2 , between the discharge roller 12 and the water-cooled roller 11, symmetrically distributed wiper blades 15 are arranged. Both ends of 15 are provided with symmetrically distributed first positioning plates 14 , and the bottom of the first positioning plates 14 is fixedly connected with the upper end of the water cooling pool 1 .

[0028] The design of the wiper 15 enables the large amount of moisture on the surface of the stretched film 2 to be quickly separated from the surface of the film after water cooling, thereby improving the overall drying efficiency.

[0029] The two ends of the wiper blade 15 on one side are provided with symmetrically distributed connecting shafts 151, and the connecting shafts 151 are connected to the first positioning plate 14 through a torsion spring (not shown in the figure). The wiper blade 15 is fixedly connected with the...

Embodiment 3

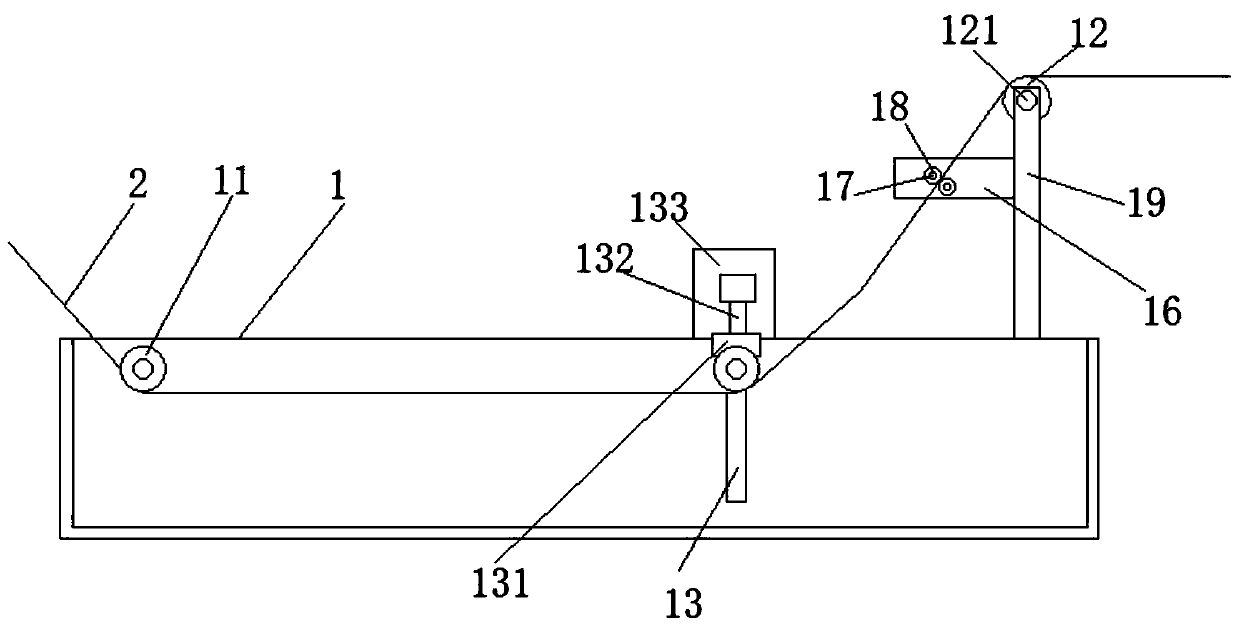

[0033] The same as embodiment 1 is no longer repeated, and the difference with embodiment 1 is:

[0034] see Figure 3-4 , both ends of the water-cooled roller 11 are provided with symmetrically distributed adjusting shafts 111, and the inner wall of the water-cooled pool 1 is provided with symmetrically distributed adjusting grooves 13 that match the adjusting shafts 111, and the adjusting grooves 13 are provided with reset Spring 134, one end of the return spring 134 is connected to the bottom of the adjustment groove 13, and the other end of the return spring 134 is connected to the adjustment shaft 111, and the middle part of the upper end of the water-cooled roller 11 is provided with a pressure block 131 that matches the size of the water-cooled roller 11. The upper end of the pressing block 131 is provided with a hydraulic rod 132 that can move up and down.

[0035] The design of the adjustment groove 13 and the hydraulic rod 132 enables the stretched film 2 to move do...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com